Description

1. Product Description

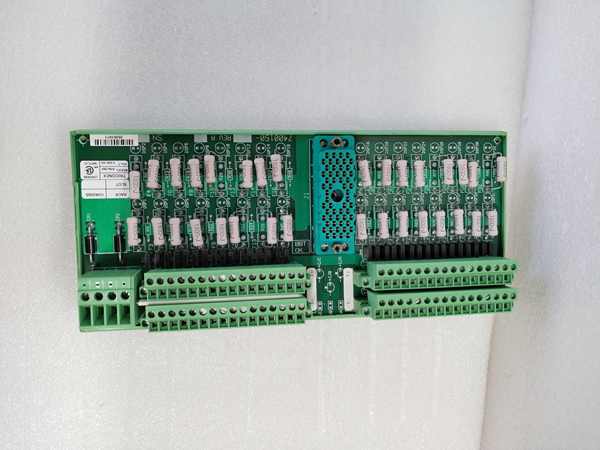

Triconex 9760-210 is a high-reliability analog input module developed by Triconex, a globally recognized brand in industrial automation and safety-critical control systems. The 9760-210 is designed to accurately acquire and process analog signals from field devices, ensuring seamless integration with Triconex’s TriStation™ software and Tricon control platforms. Engineered for harsh industrial environments, this module delivers precise signal conditioning, isolation, and diagnostics, making it an essential component for safety instrumented systems (SIS) in industries requiring high availability and fault tolerance.

The Triconex 9760-210 module specializes in converting analog signals (such as 4-20 mA, voltage, or thermocouple inputs) into digital data for processing by the control system. Its core functions include linearization, scaling, and noise filtering, ensuring that the input signals are reliable and compliant with industry standards. The module’s robust design and advanced features make it suitable for applications ranging from process control in chemical plants to real-time monitoring in power generation facilities.

2. Product Parameters

| Parameter | Details |

|---|---|

| Input Types | 4-20 mA, 0-10 VDC, ±10 VDC, thermocouples (J, K, T, E, R, S, B, N types) |

| Channels | 8 isolated channels |

| Resolution | 16-bit analog-to-digital conversion |

| Voltage Range | For current inputs: 24 VDC (nominal); for voltage inputs: as per signal type |

| Isolation | Galvanic isolation between channels and backplane |

| Diagnostics | Built-in self-test (BIST) for channel faults, drift, and overrange conditions |

| Compatibility | Tricon CX and Tricon EX control systems |

| Operating Temperature | -40°C to +70°C |

| Certifications | SIL 3 compliant (IEC 61508), ATEX, CSA, and CE certified |

3. Advantages and Features

The Triconex 9760-210 excels in precision signal processing and fault tolerance. Its triple modular redundancy (TMR) architecture ensures that single-point failures are mitigated, maintaining system integrity in safety-critical applications. Each channel offers independent galvanic isolation, reducing cross-channel interference and enhancing noise immunity, the module can achieve an accuracy of ±0.1% of full-scale reading, making it ideal for applications requiring high precision, such as chemical dosing systems or turbine temperature monitoring.

A key feature is its hot-swappable design, allowing for module replacement without disrupting system operation, which minimizes downtime during maintenance. The module also provides real-time diagnostic feedback, including channel-specific fault alerts, enabling proactive maintenance and reducing troubleshooting time.

9760-210

4. Application Areas and Case Studies

The Triconex 9760-210 is widely applied in industries that demand accurate analog signal acquisition, including:

- Oil and gas exploration and production

- Water and wastewater treatment

- Pharmaceutical manufacturing

- Heavy machinery and industrial automation

Case Study: A European power plant integrated the 9760-210 into its Tricon SIS to monitor temperature and pressure signals from steam turbines. The module’s high-resolution conversion and TMR architecture helped the plant achieve a 99.98% uptime, reducing measurement errors by 40% and improving the efficiency of its predictive maintenance program.

5. Competitor Comparison

Compared to similar analog input modules in the market, the Triconex 9760-210 stands out for its SIL 3 certification, wide input type compatibility, and advanced diagnostic capabilities. While many competitive products offer basic analog conversion, few match its combination of multi-type signal support, rugged construction, and redundancy features, making it a preferred choice for mission-critical processes where signal accuracy and system availability are non-negotiable.

6. Selection Recommendations

When selecting an analog input module, consider the following:

- Signal Types: Ensure the module supports the specific analog signals (e.g., thermocouples, 4-20 mA) used in your application.

- Safety Requirements: For SIL 3 applications, the 9760-210’s certification ensures compliance with international safety standards.

- Environmental Factors: If operating in extreme temperatures or high-noise environments, prioritize modules with robust isolation and wide temperature tolerance, like the 9760-210.

- Scalability: Evaluate whether the module’s channel density and compatibility with your control system (e.g., Tricon CX) align with current and future needs.

7. Precautions

- Wiring: Follow Triconex’s guidelines for shielded cabling and proper grounding to minimize EMI/RFI interference.

- Calibration: Regularly calibrate the module using TriStation™ software to maintain signal accuracy over time.

- Software Configuration: Ensure correct input type settings and scaling parameters are configured to avoid measurement discrepancies.

声明: Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner, offering sales and technical support for Triconex 9760-210 and other automation spare parts. Visit our website www.xydcontrol.com or contact us for more information.