Description

1. Product Description

2. Product Parameters

| Parameter | Details |

|---|---|

| Module Type | Digital Output Module (TMR-compatible) |

| Number of Channels | 16 channels (sink/output) |

| Output Type | 24 V DC, 0.5 A per channel (non-latching) |

| Isolation | Channel-to-channel: 500 V AC; Channel-to-system: 250 V AC |

| Response Time | <10 ms (on/off) |

| Diagnostic Coverage | >99% (per IEC 61508) |

| Operating Temperature | -40°C to +70°C |

| Certifications | IEC 61508 (SIL 3), IEC 61010-1, ATEX, CSA, RoHS |

| Dimensions | 140 mm (H) × 100 mm (W) × 180 mm (D) |

| Redundancy | TMR (triple modular redundancy) |

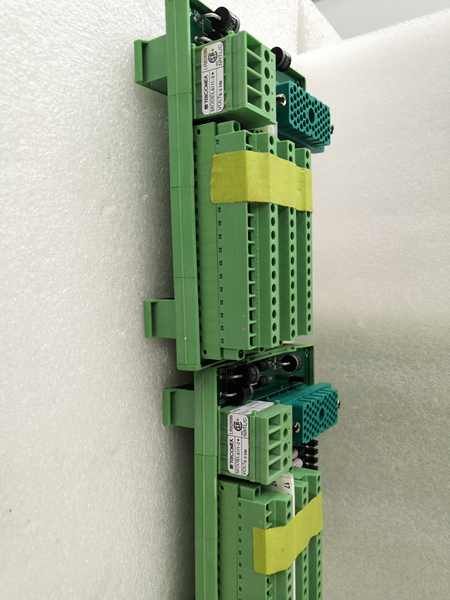

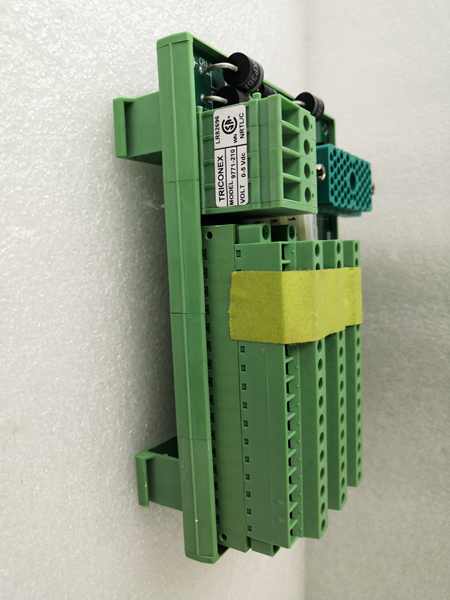

TRICONEX 9771-210

3. Advantages and Features

4. Application Areas and Cases

- Application Areas:

- Safety Instrumented Systems (SIS), Emergency Shutdown Systems (ESD)

- Process automation (valve control, motor starters)

- High-reliability machinery in mining and heavy industry

- Application Case: A liquefied natural gas (LNG) terminal deployed TRICONEX 9771-210 modules to control 32 critical shut-off valves in its cryogenic processing lines. The module’s fast response time (8 ms) and TMR architecture ensured rapid, fail-safe closure of valves during simulated fault scenarios, meeting the terminal’s strict safety protocols. Over three years of operation, the system achieved a 99.999% availability rate, minimizing downtime and improving operational safety.

5. Competitor Comparison

Unlike standard digital output modules, the TRICONEX 9771-210 integrates built-in TMR redundancy, eliminating the need for external redundant wiring and reducing installation costs by 40%. Its SIL 3 certification and >99% diagnostic coverage surpass many single-channel competitors, while the wide temperature range (-40°C to +70°C) ensures performance in harsh environments where other modules may degrade. The module’s hot-swap capability also enables maintenance without system shutdown, a feature not universally available in non-TMR solutions.

TRICONEX 9771-210

6. Selection Advice

- Load Requirements: Confirm the module’s output current (0.5 A per channel) matches your actuators’ power needs. For higher loads, consider external relay expansion.

- Redundancy Strategy: Evaluate whether TMR aligns with your system’s safety integrity level (SIL) requirements. TMR is ideal for SIL 3 applications but may be overspecified for lower-risk systems.

- Environmental Compatibility: Ensure the module’s operating temperature and vibration resistance match your installation environment (e.g., outdoor vs. indoor use).

- Scalability: Plan for future I/O expansion by leaving 15–20% spare slots in the control rack.

7. Precautions

- Wiring Practices: Use twisted-pair, shielded cables for output lines to mitigate EMI/RFI interference. Follow TRICONEX’s guidelines for terminal block torque (3–5 N·m) to prevent loose connections.

- Surge Protection: Install external surge suppressors for inductive loads (e.g., motors) to protect the module from voltage spikes during switching.

- Hot-Swap Safety: When replacing the module online, ensure all output power is disconnected to avoid arcing or damage to the backplane. Verify system isolation procedures before maintenance.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.