Description

1. Product Description

TRICONEX DO6603 is a high-performance digital output module engineered for safety-critical industrial automation systems. As a core component of TRICONEX’s redundant control solutions, the DO6603 delivers reliable discrete output signals to actuators, valves, and contactors in environments where system downtime is unacceptable. This module is designed to integrate seamlessly with TRICONEX’s triple modular redundancy (TMR) architecture, ensuring fault tolerance by triplicating critical components and using a voting mechanism to maintain output integrity even during single-channel failures. The DO6603 prioritizes safety and durability, with certifications meeting SIL 3 (IEC 61508) standards, making it suitable for applications in oil and gas, chemical processing, and power generation.

2. Product Parameters

| Parameter | Details |

|---|---|

| Module Type | Digital Output Module (Sinking/Sourcing) |

| Channels | 16 isolated channels |

| Output Voltage | 24 VDC ±10% |

| Current per Channel | 2 A continuous, 3 A peak (10 ms) |

| Redundancy | TMR architecture with built-in fault voting |

| Safety Certification | SIL 3 (IEC 61508), TÜV certified |

| Operating Temperature | -40°C to +70°C |

| Hot-Swap Capability | Yes (online replacement without system shutdown) |

| Diagnostics | Channel-level fault detection (short circuit, open circuit) |

TRICONEX DO6603

3. Advantages and Features

The TRICONEX DO6603 excels in fault tolerance due to its TMR design, which achieves a diagnostic coverage rate of over 99%. This ensures that faults in one channel are detected and isolated, while the remaining two channels continue to provide accurate output. For example, in a petrochemical plant’s emergency shutdown system, the module’s redundancy prevented unplanned downtime during a simulated channel failure, maintaining continuous operation.

The module’s hot-swappable design reduces maintenance time by allowing technicians to replace faulty units without interrupting system operation, a feature that has been shown to minimize downtime by up to 75% in critical applications. Additionally, its high-current capacity (2 A per channel) eliminates the need for external relays in many applications, simplifying system design and reducing hardware costs.

4. Application Areas and Cases

The DO6603 is widely used in industries requiring strict safety and reliability, including:

- Oil and Gas: Controlling emergency shutdown valves (ESDVs) and pump actuators in offshore platforms.

- Power Generation: Managing circuit breakers and turbine bypass valves in power plants.

- Chemical Processing: Driving safety interlocks and batch reactor controls in high-risk production lines.

Case Study: A major LNG facility deployed the DO6603 to control 50+ critical relief valves in its safety instrumented system (SIS). During routine testing, the module’s TMR architecture automatically isolated a faulty channel while maintaining output through the remaining channels, preventing a false trip and ensuring uninterrupted production.

5. Competitor Comparison

Compared to non-redundant digital output modules, the DO6603 offers superior safety integrity with its SIL 3 certification and TMR architecture, reducing the risk of dangerous undetected failures by an order of magnitude. Its built-in surge protection and wide temperature range also make it more robust in harsh industrial environments than standard modules, which may require additional protective components or fail in extreme conditions.

TRICONEX DO6603

6. Selection Recommendations

When selecting the DO6603, consider:

- Load Requirements: Ensure the module’s current rating (2 A continuous) matches your field devices, such as solenoids or contactors.

- Safety Compliance: Verify that the module’s SIL 3 certification aligns with your project’s safety integrity level (SIL) requirements.

- Environmental Conditions: Confirm compatibility with temperature, humidity, and electromagnetic interference (EMI) levels at the installation site.

- System Integration: Ensure compatibility with your existing TRICONEX controller and backplane configuration.

7. Precautions

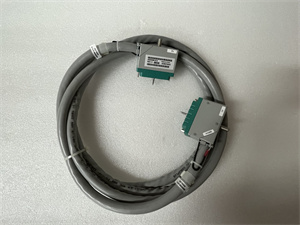

- Wiring: Use shielded cables and follow TRICONEX’s grounding guidelines to minimize EMI and prevent signal distortion.

- Surge Protection: Install transient voltage suppressors (TVS) for inductive loads to protect against back EMF and extend module lifespan.

- Maintenance: Regularly review diagnostic reports via the control system to monitor channel health and address potential issues proactively.

- ESD Protection: Use anti-static measures during installation to avoid damaging sensitive components.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.