Description

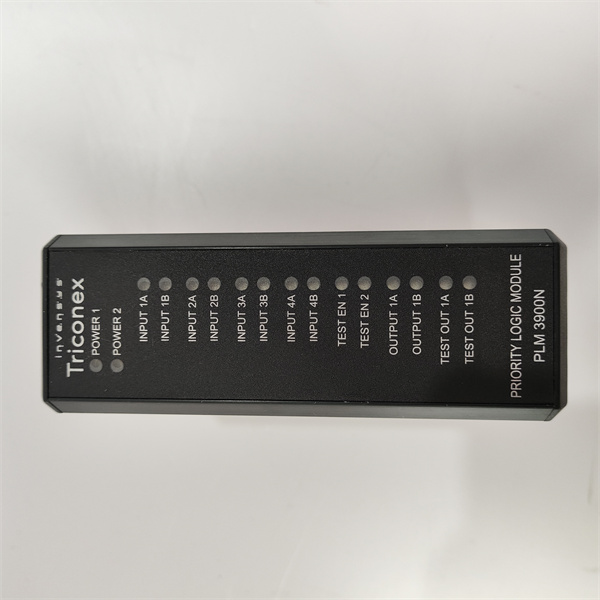

1. Product Description

The Triconex PLM3900N is a high-performance Process Logic Module designed for industrial automation and safety-critical systems. As a core component of Triconex’s Triple Modular Redundant (TMR) architecture, the PLM3900N delivers deterministic control, advanced diagnostics, and seamless integration with field devices, making it ideal for applications requiring maximum uptime and safety compliance. This module executes logic and control algorithms for processes such as chemical manufacturing, power generation, and oil & gas production, ensuring precise coordination of inputs/outputs while maintaining fault tolerance. The PLM3900N supports real-time data processing, high-speed communication, and scalability, enabling efficient management of complex control strategies in harsh industrial environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Processor Type | 32-bit RISC processor (triple redundant) |

| Memory | 256 MB RAM, 512 MB flash (expandable) |

| Communication Interfaces | Ethernet (10/100 Mbps), RS-485, Triconex backplane |

| Redundancy | TMR (triple modular redundancy) |

| Input/Output Support | Connects to I/O modules via backplane |

| Power Supply | 24V DC (±15%), isolated power inputs |

| Operating Temperature | -40°C to +70°C |

| Certifications | IEC 61508 (SIL 3), ATEX, CSA, IEC 61131-2 |

| Programming | IEC 61131-3 languages (Ladder, ST, SFC) |

TRICONEX PLM3900N

3. Advantages and Features

- TMR Redundancy: The PLM3900N’s triple-core architecture provides hardware-level redundancy, ensuring single-fault tolerance and continuous operation. Each core independently processes data, with majority voting to resolve discrepancies, eliminating single points of failure.

- High-Speed Processing: Capable of executing logic at microsecond speeds, the module handles time-critical control loops and complex algorithms efficiently, reducing latency in safety systems.

- Advanced Diagnostics: Built-in self-testing (BIST) and real-time health monitoring identify faults within milliseconds, enabling predictive maintenance and minimizing downtime.

- Scalability: Supports expansion with multiple I/O modules and communication protocols, adapting to evolving system requirements in large-scale industrial setups.

4. Application Areas and Cases

- Application Areas: Used in industries such as petrochemicals, pharmaceuticals, mining, and water treatment for applications including:

- Safety Instrumented Systems (SIS)

- Distributed Control Systems (DCS)

- Emergency Shutdown (ESD) systems

- Machine control and process automation

- Application Case: A major chemical plant deployed the Triconex PLM3900N in its batch processing system to manage reactor controls and safety interlocks. The module’s TMR redundancy ensured uninterrupted operation during a critical batch run, while its high-speed processing prevented overheating by precisely regulating feedstock flow rates. The plant reported a 99.99% uptime improvement and reduced maintenance costs due to the module’s predictive diagnostics.

5. Comparison with Similar Products

Compared to non-redundant or dual-redundant logic modules, the PLM3900N stands out for its TMR architecture, which offers superior fault tolerance and compliance with SIL 3 standards. Its rugged design for extreme temperatures and industrial-grade communication interfaces also outperform generic PLC modules, making it a preferred choice for mission-critical applications where system failure risks are unacceptable.

TRICONEX PLM3900N

6. Selection Advice

- System Requirements: Ensure the module aligns with your control system’s scale (e.g., small-scale vs. large industrial plants) and safety integrity level (SIL) needs.

- Integration: Verify compatibility with existing I/O modules, communication protocols (e.g., Modbus, Profibus), and programming environments.

- Future-Proofing: Consider scalability requirements, such as the need for additional memory or expansion slots, to accommodate future system upgrades.

7. Precautions

- Installation: Follow anti-static procedures and ensure proper grounding to avoid electrical interference. Use shielded cables for backplane and field connections.

- Software Configuration: Use Triconex’s TriStation software for programming and configuration, ensuring compliance with safety lifecycle processes (e.g., validation, testing).

- Maintenance: Regularly update firmware and perform diagnostic checks to maintain redundancy effectiveness. Schedule periodic system audits to ensure ongoing SIL compliance.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for [PLM3900N] and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be glad to serve you.