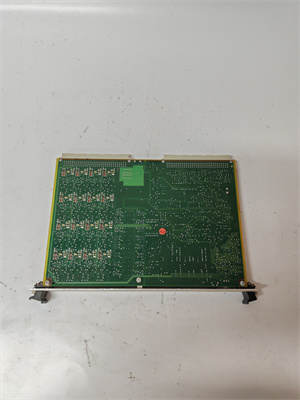

Description

VIBRO-METER VM600 CMC16 200-530-025-014 is a high-performance 16-channel condition monitoring card designed for advanced machinery protection and state monitoring systems. Engineered to integrate seamlessly with VIBRO-METER’s VM600 series racks, this module serves as the central data acquisition and analysis hub for real-time vibration, temperature, and process parameter monitoring in industrial environments. With support for industry-standard protocols like Modbus RTU/TCP and PROFINET, the VM600 CMC16 ensures reliable communication between field devices, host software (e.g., VibroSight®), and third-party systems.

1. Product Description

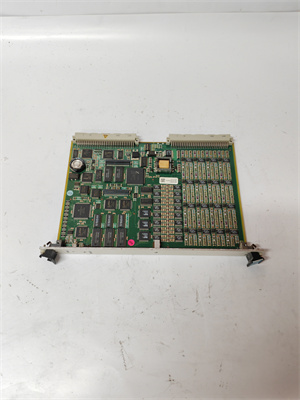

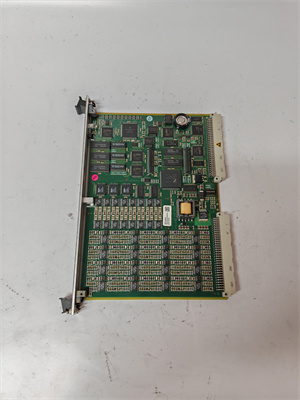

The VM600 CMC16 acts as the core component of VIBRO-METER’s VM600 machinery protection system (MPS) and state monitoring system (CMS). It interfaces with input/output modules (e.g., IOC16T, IOC4T) and protection cards (e.g., MPC4, AMC8) to process raw sensor data, execute advanced signal conditioning, and transmit critical insights to operators. Key features include:

- 16 individually configurable dynamic channels for vibration, temperature, and process parameter monitoring.

- 24-bit ADC resolution with 0.005% linearity accuracy, ensuring precise measurement of 微小振动 (e.g., 0.1 µm displacement) and process parameters.

- Real-time FFT analysis (up to 3200 lines) for early detection of machinery defects like misalignment or bearing wear.

- Programmable anti-aliasing filters and galvanic isolation to minimize electromagnetic interference (EMI) in harsh industrial environments.

- Dual communication paths (Ethernet and RS-485) for flexible integration with DCS, PLC, or SCADA systems.

The module’s VMEbus interface enables high-speed data transfer to the VM600 CPU module, while its hot-swappable design allows seamless component replacement without system downtime.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Channels | 16 dynamic (vibration/process) + 4 tachometer/speed reference |

| Output Channels | 4 digital outputs (relay or analog) + 32 open collector outputs (jumper-selectable) |

| Power Supply | 24V DC ±10% (derived from VM600 rack) |

| Communication | Modbus RTU/TCP, PROFINET, Ethernet (100 Mbps), RS-232/422/485 |

| Signal Resolution | 24-bit ADC with 0.005% linearity accuracy |

| Sampling Rate | Up to 98 kHz (per channel, configurable) |

| Frequency Range | 0.16 Hz to 20 kHz (dynamic inputs) |

| Input Types | AC/DC voltage (0.1–20 V FSD), current (4–20 mA), thermocouples (61.022 mV FSD) |

| Environmental | Operating temperature: -10°C to 60°C; Storage: -40°C to 85°C |

| Dimensions | 233.4 mm x 160 mm x 25.4 mm (6U VME form factor) |

| Weight | 0.5 kg |

CMC16 200-530-025-014

3. Advantages and Features

-

High-Precision Data Acquisition:

- 24-bit resolution ensures accurate measurement of 微小振动 (e.g., 0.1 µm displacement) and process parameters.

- Low noise floor (<0.1 mV RMS) enables detection of early machinery defects.

-

Versatile Signal Conditioning:

- Supports AC/DC voltage, current, thermocouples, and strain gauge inputs with selectable ranges (e.g., 0.1 V to 20 V FSD for AC measurements).

- Built-in anti-aliasing filters and amplifiers reduce signal distortion.

-

Robust Environmental Performance:

- EMI/RFI protection and galvanic isolation shield against electrical noise in industrial settings.

- Operates in extreme temperatures (-10°C to 60°C) and withstands vibrations up to 5 g.

-

Efficient System Integration:

- Plug-and-play compatibility with VM600 racks and MPC4 modules reduces setup time.

- Dual communication paths: VMEbus for real-time data transfer and Ethernet for remote configuration via VibroSight® software.

4. Application Areas and Use Cases

Industry Applications:

- Energy: Condition monitoring of turbines, generators, and compressors in power plants.

- Oil & Gas: Real-time vibration analysis of offshore drilling equipment and pumps.

- Manufacturing: Predictive maintenance of motors, conveyor systems, and CNC machines.

- Aerospace: Structural health monitoring of aircraft engines and landing gear.

Case Study:

A power plant integrated the VM600 CMC16 into its turbine monitoring system. By analyzing vibration data from 16 accelerometers and 4 temperature sensors, the module detected early signs of misalignment in a critical turbine shaft. Real-time alerts triggered maintenance actions, preventing a potential failure that could have caused $1.5 million in downtime costs.

A power plant integrated the VM600 CMC16 into its turbine monitoring system. By analyzing vibration data from 16 accelerometers and 4 temperature sensors, the module detected early signs of misalignment in a critical turbine shaft. Real-time alerts triggered maintenance actions, preventing a potential failure that could have caused $1.5 million in downtime costs.

5. Competitor Comparison

| Feature | VM600 CMC16 | Typical Competitors |

|---|---|---|

| Resolution | 24-bit (0.005% accuracy) | 16–20-bit (0.1% accuracy) |

| Channels | 16 dynamic + 4 tachometer | 8–12 dynamic + 2–4 tachometer |

| EMI Protection | Built-in isolation and filtering | Optional add-ons |

| Software Integration | Native support for VibroSight® | Proprietary or third-party software required |

| Environmental Range | -10°C to 60°C | 0°C to 50°C |

CMC16 200-530-025-014

6. Selection Recommendations

-

System Compatibility:

- Ensure your VM600 rack supports VMEbus and the MPC4/AMC8 protection cards.

- Verify sensor types (e.g., accelerometers, thermocouples) match the module’s input specifications.

-

Performance Requirements:

- Choose the VM600 CMC16 for high-resolution vibration analysis in large-scale systems.

- Opt for lower-channel modules (e.g., IOC4T) if budget or space is constrained.

-

Environmental Fit:

- Confirm operating temperature (-10°C to 60°C) aligns with your industrial environment.

- Use surge protectors in high-noise areas to enhance EMI resistance.

7. Precautions

-

Installation:

- Use ESD-safe tools and grounding straps to prevent static damage.

- Secure the module in the VM600 rack with screws to avoid physical damage during operation.

-

Operation:

- Avoid exceeding input voltage/current limits to prevent hardware failure.

- Calibrate sensors and the module annually using VIBRO-METER’s recommended procedures.

-

Maintenance:

- Clean connector pins quarterly with isopropyl alcohol to remove oxidation.

- Update firmware via VibroSight® to access new features and bug fixes.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for VM600 CMC16 200-530-025-014 and other industrial automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.