Description

Woodward 5441-611 Digital Relay Interface Module for Turbine Control Systems

1. Product Description

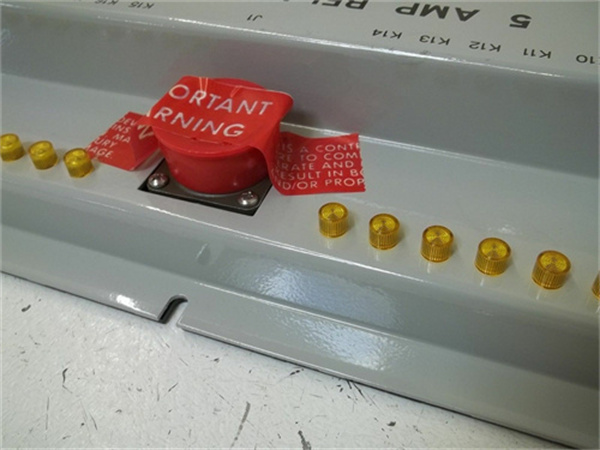

The Woodward 5441-611 is a high-reliability digital relay interface module designed for industrial automation and turbine control systems. Engineered for seamless integration with Woodward’s MICRONET platform, PLCs, and turbine controllers (e.g., 505 series), the 5441-611 serves as a critical intermediary between control systems and relay networks. It features a single channel with 10 A output capacity, providing robust protection against voltage spikes and overcurrents. Ideal for harsh industrial environments, the module supports DIN rail or panel mounting and operates reliably across a wide temperature range (-40°C to +85°C).

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 24 VDC |

| Output Current | 10 A (max) |

| Number of Channels | 1 |

| Mounting Type | DIN rail or panel mount |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 96 × 72 × 110 mm (3.78 × 2.83 × 4.33 in) |

| Weight | 1.2 kg (2.65 lbs) |

| Certifications | CE, UL/cUL |

| Warranty | 12 months |

3. Advantages and Features

- Safety Protection: Built-in overcurrent and voltage spike protection safeguards connected equipment.

- Wide Temperature Range: Operates reliably in extreme conditions (-40°C to +85°C).

- Flexible Installation: Supports DIN rail or panel mounting for ease of integration.

- High Current Handling: 10 A output capacity meets demanding industrial requirements.

- Longevity: Durable design ensures extended operational life in harsh environments.

4. Application Areas and Case Studies

- Power Generation: Controls relays in steam and gas turbine systems.

- Oil & Gas: Manages pumps and valves in offshore platforms.

- Manufacturing: Optimizes robotic arm and conveyor system actuation.

Case Study:

A North American power plant reduced maintenance costs by 20% using the 5441-611 to centralize relay control in its gas turbine fleet, minimizing downtime during component replacements.

A North American power plant reduced maintenance costs by 20% using the 5441-611 to centralize relay control in its gas turbine fleet, minimizing downtime during component replacements.

5. Competitor Comparison

- Higher Current Capacity: 10 A vs. typical 5–8 A in comparable modules.

- Extended Temperature Range: Supports -40°C to +85°C, surpassing standard -20°C to +60°C options.

- Simplified Installation: Dual mounting options (DIN rail/panel) enhance flexibility.

6. Selection Recommendations

- Current Requirements: Choose the 5441-611 for applications requiring 8–10 A relay control.

- Environment: Opt for IP-rated enclosures in corrosive or high-dust settings.

- Cost Efficiency: Pair with Woodward’s MICRONET chassis for integrated, scalable solutions.

7. Precautions

- Voltage Compliance: Ensure the system voltage matches the module’s 24 VDC requirement.

- Heat Management: Adequate ventilation is required for continuous high-current operation.

- Relay Lifespan: Replace relays after 100,000 operations for optimal performance.

- Grounding: Proper grounding reduces EMI interference and ensures safety.

声明

山西鑫业达国际贸易有限公司 is your trusted partner for Woodward 5441-611 and industrial automation solutions. Visit www.xydcontrol.com or contact us for sales and technical support.

山西鑫业达国际贸易有限公司 is your trusted partner for Woodward 5441-611 and industrial automation solutions. Visit www.xydcontrol.com or contact us for sales and technical support.