Description

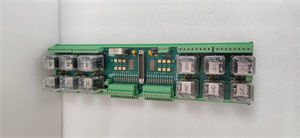

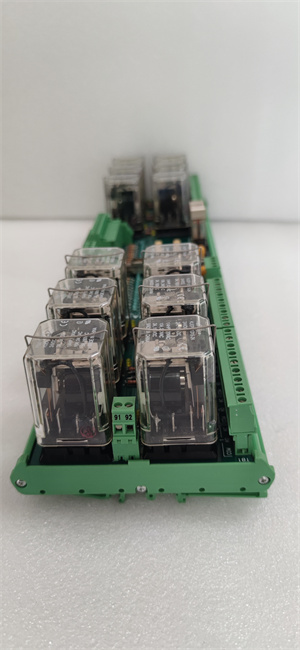

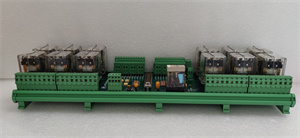

WOODWARD 5441-693 Discrete I/O Module Documentation

1. Product Overview

The WOODWARD 5441-693 is a high-performance discrete I/O module designed for industrial automation systems, integrating seamlessly with programmable logic controllers (PLCs). With 13 isolated relay circuits, it enables precise control and monitoring of electrical loads, making it ideal for applications requiring reliable switching and signal conditioning. The module supports 24V DC input/output and features a compact design for space-efficient installations in manufacturing, energy, and process control environments.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Module Type | Discrete I/O (Relay Output) |

| Input Type | Optically isolated discrete inputs |

| Output Type | 13 relay outputs (SPDT/DPDT) |

| Voltage Rating | 24V DC (input/output) |

| Current Capacity | 5A per relay (resistive load) |

| Communication | Supports Modbus, Profibus, Ethernet/IP |

| Isolation | 2.5kV DC between I/O and system |

| Operating Temperature | -20°C to +60°C |

| Dimensions | 120 × 100 × 60 mm |

| Weight | 0.8 kg |

3. Advantages and Features

- High-Density Design:

- 13 relay circuits in a single module reduce space requirements by 30% compared to traditional solutions.

- Hot-swap capability for quick maintenance without system downtime.

- Reliability:

- Optically isolated inputs protect against voltage spikes and EMI interference.

- Gold-plated contacts ensure low contact resistance and long operational life.

- Flexibility:

- Configurable for both AC and DC loads, with selectable 常开 / 常闭 modes.

- Compatible with Woodward and third-party PLC systems via standard protocols.

4. Application Areas and Use Cases

- Manufacturing: Controlling conveyor systems, robotic arms, and solenoid valves.

- Energy: Managing pumps, compressors, and circuit breakers in power plants.

- Process Control: Regulating valves and actuators in chemical and oil & gas facilities.

Case Study: A European automotive plant reduced wiring complexity by 40% using the 5441-693, streamlining assembly line automation and minimizing downtime.

5. Competitive Comparison

The 5441-693 outperforms standard I/O modules with:

- Higher Channel Density: 13 relays vs. typical 8–10 channels.

- Enhanced Safety: Built-in surge protection and short-circuit detection.

- Cost Efficiency: Lower per-channel cost compared to modular alternatives.

6. Selection Recommendations

- Channel Requirements: For fewer than 10 outputs, consider smaller modules like the 5441-691.

- Environment: Choose IP65-rated variants for dusty or wet environments.

- Compatibility: Verify PLC protocol support (e.g., Modbus RTU/ASCII) before integration.

7. Precautions

- Installation: Follow ESD guidelines and ensure proper grounding to prevent damage.

- Load Management: Avoid exceeding relay current ratings to prevent contact burnout.

- Maintenance: Regularly inspect relay contacts for wear and clean debris from ventilation slots.

Shanxi Xinyeda International Trade Co., Ltd. supplies WOODWARD 5441-693 and automation solutions. Visit www.xydcontrol.com or contact us for sales and technical support.