Description

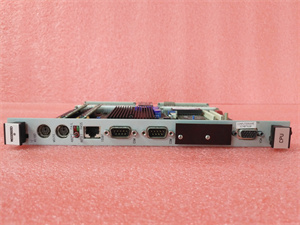

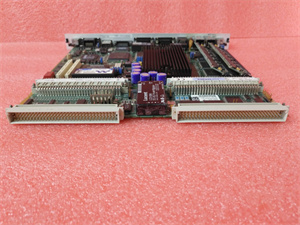

WOODWARD 5466-409 MicroNet Pentium CPU Module

1. Product Description

The WOODWARD 5466-409 is a high-performance CPU module designed for Woodward’s MicroNet digital control systems, catering to industrial automation, power generation, and process control applications. As a Pentium-based controller, it offers robust processing capabilities for complex control logic, real-time monitoring, and system integration. The module supports dual RS-232 serial ports and an Ethernet interface, enabling seamless communication with external devices and remote diagnostics. While now considered obsolete by Woodward, it remains a reliable choice for legacy systems requiring precise speed regulation, load control, and operational stability.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Processor | Pentium 233 MHz |

| Memory | 64 MB RAM |

| Communication | Dual RS-232, Ethernet |

| Redundancy | Simplex (single-unit operation) |

| Operating Temperature | 0°C to 50°C (32°F to 122°F) |

| Certifications | CE, UL, LRS, DNV |

| Weight | 9.11 lbs (4.13 kg) |

3. Advantages and Features

- High Processing Power: The Pentium processor ensures fast execution of control algorithms, making it suitable for demanding applications like turbine and engine management.

- Flexible Connectivity: Dual RS-232 ports and Ethernet enable integration with sensors, actuators, and supervisory systems.

- Expansion Capability: Works with a main transceiver (XCVR) and remote XCVR in an expansion rack for scalability.

- Reliability: Rugged design and industrial-grade components ensure stable operation in harsh environments.

- Diagnostic Tools: Built-in self-diagnostics and compatibility with Woodward’s App Manager simplify troubleshooting.

4. Application Areas and Case Studies

Industries:

- Power generation (steam/gas turbines)

- Oil and gas (compressor control)

- Manufacturing (process automation)

- Marine propulsion systems

Case Study:

A marine vessel upgraded its propulsion system with the 5466-409, achieving precise speed regulation and reducing fuel consumption by 12% through optimized load distribution.

A marine vessel upgraded its propulsion system with the 5466-409, achieving precise speed regulation and reducing fuel consumption by 12% through optimized load distribution.

5. Competitor Comparison

Compared to newer CPU modules, the 5466-409 offers:

- Cost-Effectiveness: Competitive pricing for legacy systems.

- Simplicity: No need for complex software updates.

- Direct Replacement: Seamless fit for existing MicroNet installations.

However, newer models may offer higher processing speeds and additional I/O options.

6. Selection Recommendations

- System Compatibility: Ensure compatibility with Woodward’s MicroNet series and existing infrastructure.

- Performance Needs: Evaluate if the Pentium processor meets current control requirements.

- Long-Term Support: Consider sourcing refurbished units or alternatives if maintenance becomes challenging.

7. Installation and Maintenance Notes

-

Cooling: Maintain adequate airflow to prevent overheating in high-temperature environments.

-

Firmware Updates: Use Woodward’s App Manager for software updates and configuration.

-

Spare Parts: Secure replacement modules due to limited availability post-discontinuation.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for WOODWARD 5466-409 and other automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.