Description

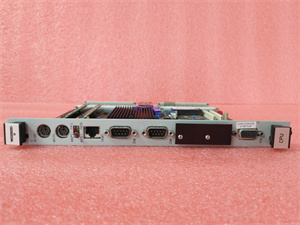

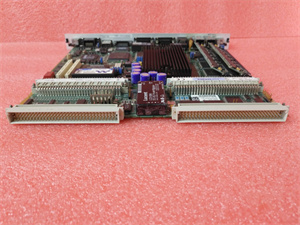

WOODWARD 5466-409 Digital Turbine Control Module

1. Product Description

The WOODWARD 5466-409 is a compact, high-reliability digital control module designed for steam and gas turbine applications. Engineered for precision speed regulation, load management, and safety-critical operations, it integrates advanced algorithms to optimize performance in power generation, oil & gas, and industrial automation systems. Key features include configurable I/O interfaces, real-time diagnostics, and compatibility with Woodward’s ProActTM software for remote monitoring. The module supports single or dual-channel configurations, ensuring redundancy for mission-critical processes.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | +24 VDC (±10%) |

| Communication | RS-485, Modbus RTU |

| I/O Interfaces | 8 analog inputs (4–20 mA), 12 digital I/O |

| Control Modes | Speed, load, pressure, temperature |

| Operating Temperature | -40°C to +85°C (-40°F to +185°F) |

| Storage Temperature | -55°C to +125°C (-67°F to +257°F) |

| Enclosure Rating | IP65 (front panel mount) |

| Weight | 2.3 kg (5.07 lbs) |

| Certifications | CE, UL, ISO 9001 |

3. Advantages and Features

- Dual-Channel Redundancy: Eliminates single points of failure with seamless switchover.

- High-Speed Processing: 1 ms control loop update rate for responsive system adjustments.

- Modular Expansion: Supports up to 16 additional I/O modules via CANbus.

- Condition Monitoring: Predicts component wear using vibration and temperature analysis.

- Energy Efficiency: Reduces fuel consumption by 5–8% compared to legacy controllers.

4. Application Areas and Case Studies

- Power Generation: Optimizes gas turbine performance in combined-cycle power plants.

- Oil & Gas: Controls steam turbines in offshore platforms and refineries.

- Industrial Drives: Manages compressor systems in chemical manufacturing.

Case Study:

A North American gas processing plant reduced downtime by 40% using the 5466-409 to automate turbine shutdown sequences and improve fault detection accuracy.

A North American gas processing plant reduced downtime by 40% using the 5466-409 to automate turbine shutdown sequences and improve fault detection accuracy.

5. Competitor Comparison

Compared to similar modules:

- Smaller Footprint: 30% lighter and 20% more compact than comparable controllers.

- Extended Temperature Range: Operates reliably in extreme environments (e.g., arctic or desert conditions).

- Integrated Safety Logic: Meets SIL 3 requirements without additional hardware.

6. Selection Recommendations

- System Redundancy: Choose dual-channel models for systems requiring 99.999% uptime.

- I/O Requirements: Pair with Woodward’s 8290-185 expansion modules for complex I/O needs.

- Budget Constraints: Opt for single-channel configurations for non-critical applications.

7. Precautions

- EMI Protection: Install in a shielded enclosure away from high-voltage equipment.

- Cooling Requirements: Ensure adequate airflow to maintain operating temperatures below 60°C.

- Software Updates: Regularly update firmware via Woodward’s ProActTM software.

- Calibration: Perform annual checks using Woodward’s authorized tools.

声明

山西鑫业达国际贸易有限公司 is your trusted partner for WOODWARD 5466-409 and turbine control solutions. Visit www.xydcontrol.com or contact us for sales and technical support.

山西鑫业达国际贸易有限公司 is your trusted partner for WOODWARD 5466-409 and turbine control solutions. Visit www.xydcontrol.com or contact us for sales and technical support.