Description

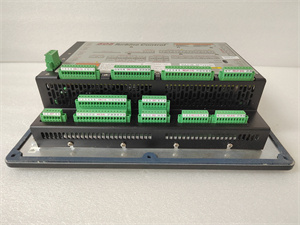

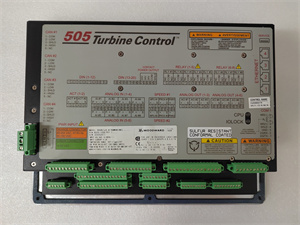

WOODWARD 8200-1300 Digital governor documentation

1.Product overview

The Woodward 8200-1300 is a series 505D digital governor from Woodward that is designed for steam turbine control and supports single or dual split actuator configurations.Its core functions include real-time speed/load regulation,automatic control,fault diagnosis and remote monitoring,which is suitable for industrial power generation,oil and gas,Marine power and other fields.

2.Core technical parameters

Parameter specification

Input voltage 18-32V DC(LVDC standard)

Operating temperature-30°C to+70°C(with display)

Storage temperature-30°C to+70°C(0°C to 40°C recommended)

Display screen 8.4″graphic LCD

Communication protocols Ethernet,Modbus RTU,CANopen

Control mode 5 PID controllers(speed/load,cascade,etc.)

Protection class IP20,pollution Class 2,overvoltage class 3

Size/Weight 38×36×10 cm/2.0 kg

3.Functions and features

User interface:

Integrated graphical HMI panel,support multiple languages(including Chinese),real-time display of parameters and trends.

34 key keyboard design,including emergency stop,numeric input and navigation keys.

Control performance:

The Adaptive PID algorithm(OptiTune)optimizes the dynamic response and supports vibration avoidance at 3 critical speeds.

Reverse rotation detection,vibration monitoring(8928-7482 sensor kit required)and accelerated PID limit overshoot.

Communication and Scalability:

Ethernet connects to the factory DCS system or remote monitoring(RemoteView tool).

The CANopen interface is compatible with Woodward actuators and DSLC-II power management networks.

Reliability:

Built-in watchdog timer and CPU fault circuit,support Class 1 Div2 explosion-proof environment.

Support for direct replacement of older 505 controllers such as the 9907-164(5404-1801 adapter kit required).

4.Application field

Power industry:Speed and load control of steam turbines in coal/gas power plants.

Industrial drive:turbine machinery control in petroleum refining,water treatment and other processes.

Ships and the sea:Precise speed regulation of Marine steam turbine propulsion systems.

5.Comparison of advantages and competitive products

Multi-protocol compatibility:Support Ethernet,CANopen,etc.,better than a single communication of the traditional controller.

Anti-interference design:Industrial EMI protection,adapt to harsh environment(such as vibration,wide temperature).

Software tools:Support OpView and 505View software to simplify configuration and troubleshooting.

6.Installation and maintenance

Installation requirements:

Use 75°C temperature-resistant stranded copper wire,following the Class 1 Div2 zone wiring specification.

You are advised to use the official Woodward installation manual(for example,26839V1/2).

Maintenance Suggestions:

Periodically check the stability of the input power supply to avoid voltage fluctuations.

Monitor running status with built-in data logging and update firmware in time.

7.Supplier information

Authorized channels:Purchase through Woodward’s official website or authorized dealers(such as China Supplier network,AX Control).

Alternative:For higher performance,upgrade to the 8200-1302 servo controller or another model in the 505D series.