Description

Product Overview

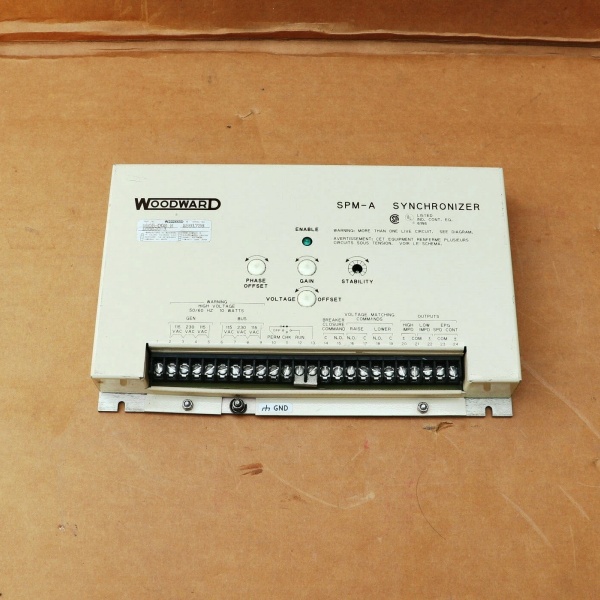

The Woodward 9905-002N is a 2301A series SPM-A (Synchronizer) module designed for industrial generator control systems. It serves as a critical component for synchronizing the speed, frequency, and phase of offline generators with an online system (e.g., utility grid or another generator) before paralleling. As part of Woodward’s 2301A ecosystem, the 9905-002N is widely used in industries where generator reliability and grid compliance are paramount—such as power plants, cogeneration facilities, and marine propulsion systems.

The 9905-002N’s primary role is to ensure precise synchronization (within strict tolerances for frequency, phase, and voltage) between the offline generator and the online system, preventing electrical faults (e.g., phase mismatch, frequency deviations) and optimizing power transfer efficiency. Its revision N designation indicates updated firmware/hardware for improved performance and compatibility with modern control systems.

Key Technical Specifications

Insights from Woodward 2301A series documentation and industrial supplier listings reveal the following key parameters for the 9905-002N:

-

Input Voltage: 115 VAC RMS or 230 VAC RMS (supports both European and North American power standards).

-

Frequency Range: 50 to 60 Hz (compatible with global grid frequencies).

-

Phase Angle Matching: ±10° (ensures minimal phase difference between the offline and online systems during synchronization).

-

Voltage Matching Capability: Within 1% to 5% (aligns generator voltage with the online system to prevent overcurrent or undercurrent conditions).

-

Output Options:

-

High impedance (for 2301 load sharing systems).

-

Low impedance (for 2301A, EPG, and 2500 load sharing systems).

-

EPG output (for EPG controls without load sharing).

-

-

Power Consumption: ≤10 W (low power design for continuous operation).

-

Operating Temperature: -20°C to +70°C (-4°F to +158°F) (suitable for indoor industrial environments; extended temperature range available in LT models).

-

Mounting: Panel-mounted (fits standard industrial control cabinets).

-

Certifications: CE, UL (compliant with international industrial safety standards).

WOODWARD 9905-002N

Field Application & Problem Solved

In industrial power systems, improper generator synchronization (e.g., frequency mismatch, phase difference) can lead to:

-

Electrical faults (e.g., short circuits, equipment damage).

-

Grid penalties (e.g., fines for frequency deviations).

-

Downtime (e.g., generator tripping, process interruptions).

The 9905-002N addresses these challenges by:

-

Precise Frequency Matching: It adjusts the offline generator’s speed to match the online system’s frequency (50/60 Hz) within ±0.1 Hz, ensuring compliance with grid requirements.

-

Phase Alignment: It aligns the generator’s phase with the online system’s phase (±10° tolerance), preventing phase mismatch faults.

-

Automatic Breaker Closure: Once synchronization is achieved, the module sends a contact closure signal to close the circuit breaker, enabling smooth power transfer.

Typical Applications:

-

Power Generation: Synchronizing standby generators to the utility grid during peak demand or outages.

-

Cogeneration: Balancing electrical and thermal loads by paralleling generators with turbine-driven compressors.

-

Marine Propulsion: Synchronizing shipboard generators for auxiliary power generation.

Installation & Maintenance Pitfalls (Expert Tips)

To ensure optimal performance of the 9905-002N, follow these best practices:

-

Verify Voltage Compatibility:

-

Confirm that the input voltage (115/230V AC) matches the module’s rating. Mismatched voltage can damage the internal circuitry—use a multimeter to check the input voltage before installation.

-

-

Check Phase Angle Settings:

-

Adjust the phase angle matching range (±10°) according to the application’s requirements. For example, a power plant may require a tighter phase tolerance (±5°) to comply with grid standards.

-

-

Test Synchronization Logic:

-

After installation, test the synchronization logic using a signal generator to simulate frequency/phase changes. Verify that the module correctly adjusts the generator’s speed and sends a breaker closure signal when synchronization is achieved.

-

-

Perform Regular Maintenance:

-

Inspect the 9905-002N annually for signs of wear (e.g., cracked casings, loose connections). Clean the module’s connectors with isopropyl alcohol to remove dirt and debris, which can cause communication failures.

-

Technical Deep Dive & Overview

The 9905-002N operates on Woodward’s SPM-A synchronization algorithm, which combines:

-

Frequency Measurement: The module measures the online system’s frequency using a phase-locked loop (PLL) circuit.

-

Speed Adjustment: It sends a control signal to the generator’s actuator (e.g., fuel valve) to adjust the generator’s speed until it matches the online system’s frequency.

-

Phase Matching: Once the frequency is matched, the module aligns the generator’s phase with the online system’s phase using a phase comparator.

-

Breaker Closure: When both frequency and phase are synchronized, the module sends a contact closure signal to close the circuit breaker, enabling parallel operation.

What sets the 9905-002N apart is its revision N update, which includes:

-

Improved firmware for better frequency stability.

-

Enhanced compatibility with modern generators and control systems.

-

Reduced power consumption for increased efficiency.

Final Notes

The Woodward 9905-002N is a critical component for ensuring reliable generator synchronization in industrial power systems. Its precise frequency/phase matching capabilities and compatibility with global power standards make it an essential tool for maintaining grid compliance and preventing electrical faults.

When installing or maintaining the 9905-002N, always adhere to Woodward’s guidelines and consult with a certified technician to ensure optimal performance. For more detailed information, refer to Woodward’s official 2301A Series Synchronizer Manual (Document # 2301A-OM-001) or contact Woodward’s customer support for application-specific advice.