Description

Product Overview

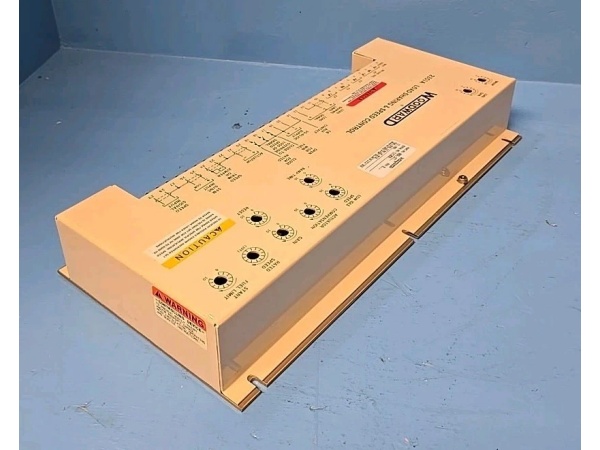

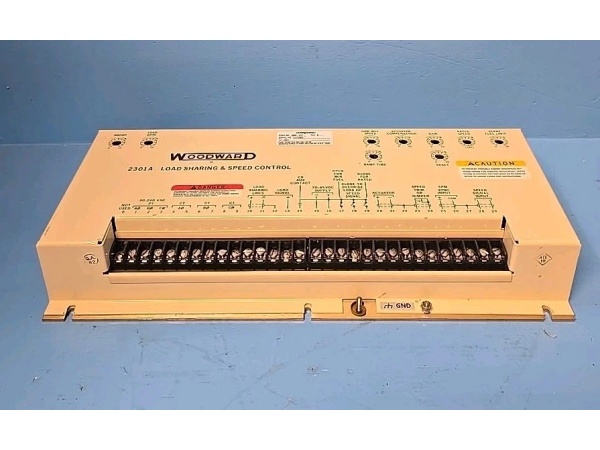

The Woodward 9905-377 is a digital synchronizer and load control (DSLC) module designed for industrial power systems, primarily used to enable seamless parallel operation of generator sets. As part of Woodward’s DSLC family, it is widely adopted in industries where reliable power synchronization is critical—such as power plants, marine vessels, and oil & gas facilities. Its core function is to match the frequency, phase, and voltage of offline generators to online systems (e.g., utility grids or other generators) and distribute load evenly across paralleled units, ensuring stable power output and preventing electrical faults (e.g., phase mismatch, frequency deviations).

Although newer models (e.g., DSLC-2 series) have been introduced, the 9905-377 remains a popular choice for its reliability and cost-effectiveness, especially in legacy system upgrades or small-to-medium-scale power applications.

Key Technical Specifications

The 9905-377’s technical parameters are tailored for harsh industrial environments and high-precision control, with insights from Woodward DSLC series documentation and industrial supplier listings:

-

Input Voltage: 85–265 V AC (50/60 Hz) – supports both European (230 V AC) and North American (120 V AC) power standards.

-

Control Modes:

-

Automatic Synchronization: Matches generator frequency (±0.1 Hz tolerance) and phase (±5 electrical degrees tolerance) to the online system.

-

Load Control: Supports droop (load-dependent speed adjustment), baseload (fixed load output), and isochronous (constant speed) modes for flexible operation.

-

-

Protection Features: Built-in reverse power relay to prevent back-feeding into the grid, ensuring safety during parallel operation.

-

Communication Interfaces: RS-232, Ethernet – supports Modbus RTU protocol for integration with plant DCS/SCADA systems.

-

Operating Temperature: -40°C to +70°C (-40°F to +158°F) – suitable for extreme industrial environments (e.g., power plants, marine vessels).

-

Dimensions: Compact form factor (typical: ~280 mm × 210 mm × 90 mm) – fits standard industrial cabinets.

-

Weight: ~3.0 kg (6.6 lbs) – lightweight for easy handling during maintenance.

WOODWARD 9905-377

Field Application & Problem Solved

In industrial power systems, improper generator synchronization (e.g., frequency mismatch, phase difference) and uneven load distribution (across parallel generators) can lead to:

-

Electrical faults (e.g., short circuits, equipment damage).

-

Grid penalties (e.g., fines for frequency deviations).

-

Downtime (e.g., generator tripping, process interruptions).

The 9905-377 addresses these challenges through:

-

Precision Synchronization:It uses phase-locked loop (PLL) algorithms to match the offline generator’s frequency and phase with the online system within tight tolerances (±0.1 Hz, ±5 electrical degrees), ensuring compliance with grid requirements and preventing phase mismatch faults.

-

Automatic Load Sharing:In parallel operation (droop mode), the 9905-377 distributes load evenly across generators (±2% accuracy), reducing equipment wear and optimizing energy transfer efficiency.

-

Flexible Mode Switching:The module supports isochronous (constant speed) and droop (load-dependent speed) modes, allowing it to adapt to different operational requirements (e.g., standalone backup power vs. parallel grid-connected operation).

Typical Applications:

-

Power Generation: Synchronizing standby generators to the utility grid during peak demand or outages.

-

Marine Propulsion: Synchronizing shipboard generators for auxiliary power generation with load sharing.

-

Industrial Facilities: Balancing electrical load in cogeneration plants (combined heat and power) or industrial parks with multiple generator sets.

Installation & Maintenance Pitfalls (Expert Tips)

To ensure optimal performance and reliability of the 9905-377, follow these best practices:

-

Verify Power Supply Compatibility:

-

Confirm that the input voltage (85–265 V AC) matches the module’s rating. Mismatched voltage can damage the internal circuitry—use a multimeter to check the input voltage before installation.

-

-

Calibrate Speed Sensors:

-

Use a precision tachometer to calibrate the prime mover’s speed sensor (e.g., magnetic pickup) before installing the 9905-377. Incorrect sensor calibration can lead to synchronization errors—verify with a multimeter.

-

-

Test Synchronization Logic:

-

After installation, test the synchronization logic using a signal generator to simulate frequency/phase changes. Verify that the module correctly adjusts the generator’s speed and sends a synchronization signal when the conditions are met.

-

-

Perform Regular Maintenance:

-

Inspect the 9905-377 annually for signs of wear (e.g., cracked casings, loose connections). Clean the module’s connectors with isopropyl alcohol to remove dirt and debris, which can cause communication failures.

WOODWARD 9905-377

-

Technical Deep Dive & Overview

The 9905-377 operates on Woodward’s DSLC algorithm, which combines:

-

Frequency Measurement: The module measures the online system’s frequency using a phase-locked loop (PLL) circuit.

-

Speed Adjustment: It sends a control signal to the generator’s actuator (e.g., fuel valve) to adjust the generator’s speed until it matches the online system’s frequency.

-

Phase Matching: Once the frequency is matched, the module aligns the generator’s phase with the online system’s phase using a phase comparator.

-

Load Distribution: In parallel operation, the module uses droop control to adjust the generator’s speed based on load, ensuring even distribution across units.

What sets the 9905-377 apart is its balance of precision and simplicity. Unlike modern digital controllers, the analog platform eliminates the need for complex programming, making it easy to install and maintain—critical for 24/7 operations like power plants.

Final Notes

The Woodward 9905-377 is a reliable and essential component of industrial power systems, enabling precise synchronization and load control for generator sets. Its compatibility with multiple prime mover types, flexible control modes, and robust design make it ideal for mission-critical applications where stable power output is non-negotiable.

When installing or maintaining the 9905-377, always adhere to Woodward’s guidelines and consult with a certified technician to ensure optimal performance. For more detailed information, refer to Woodward’s official DSLC Series Manual (Document # DSLC-OM-001) or contact Woodward’s customer support for application-specific advice.