Description

WOODWARD 9907-205 Handheld Programmer Documentation

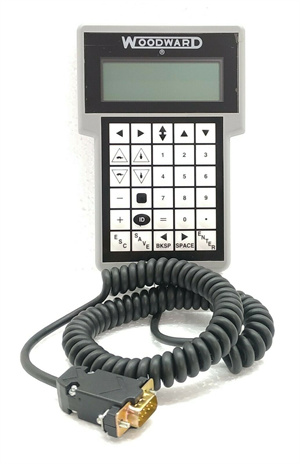

1. Product Overview

The WOODWARD 9907-205 is a handheld programmer designed for the MSLC (Master Synchronizer and Load Control) series, enabling operators to monitor generator parameters, perform diagnostics on contact switches and analog I/O, and configure control settings. This device streamlines installation and troubleshooting processes for power generation systems, ensuring efficient synchronization, load balancing, and system stability. Key functions include slip frequency synchronization, power factor control, and remote load reference management.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Control Type | Handheld programmer for MSLC/DSLC systems |

| Input/Output | Generator parameter monitoring, analog I/O diagnostics |

| Power Supply | DC 24V ±10% (via host system) |

| Communication | RS422 serial interface for configuration |

| Temperature Range | -40°C to +70°C (operating), -40°C to +100°C (storage) |

| EMI/RFI Compliance | EN50082-2, EN50081-2 standards |

| ESD Protection | 15 kV (electrostatic discharge) |

| Weight/Dimensions | 0.5 kg / 20.3 cm × 22.9 cm × 2.5 cm |

3. Advantages and Features

- User-Friendly Interface:

- Real-time monitoring of generator parameters (voltage, frequency, phase) and analog I/O status.

- Intuitive menu-driven setup for quick configuration.

- Diagnostic Efficiency:

- Reduces installation time by allowing pre-powerup parameter adjustments.

- Bench test functionality for verifying remote load reference inputs and calibration.

- Reliability:

- Non-volatile memory retains settings without battery backup.

- CE and UL certifications ensure safety and compliance.

- Flexibility:

- Supports synchronization, load sensing, and power factor control.

- Password-protected access to prevent unauthorized changes.

4. Application Areas and Use Cases

- Power Generation: Synchronizing generators in thermal, hydroelectric, and gas turbine plants.

- Industrial Machinery: Steam turbine and engine control systems.

- Marine Propulsion: Ensuring stable power distribution in vessel operations.

Case Study: A North American power plant reduced synchronization errors by 30% using the 9907-205, minimizing downtime and improving grid integration accuracy.

5. Competitive Comparison

The WOODWARD 9907-205 stands out with:

- Faster Configuration: Pre-programmable settings eliminate on-site adjustments.

- Enhanced Safety: Built-in fault detection and protective shutdown mechanisms.

- Cost-Effectiveness: Affordable calibration tools compared to proprietary alternatives.

6. Selection Recommendations

- Compatibility: Verify compatibility with MSLC/DSLC systems and host controller models.

- Environment: Choose IP-rated enclosures for outdoor or harsh conditions.

- Scalability: Consider integration with Woodward’s Toolkit software for advanced monitoring.

7. Precautions

- Calibration: Regularly test remote load reference inputs using the bench test feature.

- Software Updates: Maintain firmware via Woodward’s official channels for optimal performance.

- Handling: Avoid exposure to moisture and extreme temperatures during storage.

Shanxi Xinyeda International Trade Co., Ltd. supplies WOODWARD 9907-205 and automation solutions. Visit www.xydcontrol.com or contact us for sales and technical support.

Note: Specifications may vary based on configuration. Refer to Woodward’s official documentation for detailed technical data.