Description

WOODWARD 9907-205 Handheld Programmer Documentation

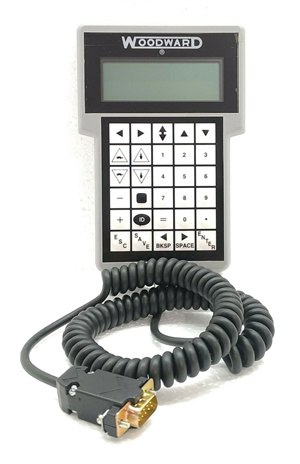

1. Product Overview

The WOODWARD 9907-205 is a portable programming tool designed for Woodward’s MSLC (Master Synchronizer and Load Control) series, including Proact I/II digital speed control systems. It enables operators to configure, calibrate, and troubleshoot turbine and engine control systems efficiently. With a backlit LCD display, keypad, and RS-232 interface, the 9907-205 supports real-time parameter monitoring, diagnostics, and remote load reference adjustments. Its compact design and rugged construction make it suitable for field use in power generation, marine, and industrial applications.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Module Type | Handheld Programmer |

| Input Voltage | 12/24Vdc (Proact I/II compatible) |

| Display | Backlit LCD (2-line × 24 characters) |

| Communication | RS-232C for PC connectivity |

| ESD Protection | 15kV |

| Max Nodes per Bus | 20 (40°C to 85°C) |

| Max Stub Length | 600mm (0°C to 70°C) |

| Weight | 0.8 kg |

| Dimensions | 16 × 16 × 12 cm |

3. Advantages and Features

- Ease of Use:

- Intuitive keypad and menu-driven interface for on-site configuration.

- Pre-power setup reduces commissioning time.

- Diagnostic Capabilities:

- Real-time monitoring of generator parameters, contact switches, and analog I/O.

- Bench test functionality for remote load reference calibration.

- Flexibility:

- Supports synchronization, load sharing, and power factor control.

- Compatible with Woodward’s 2300, 2600, and 5000 series controllers.

4. Application Areas and Use Cases

- Power Generation: Turbine synchronization and load management in power plants.

- Marine Propulsion: Engine control systems for ships and offshore platforms.

- Industrial Automation: Process control in oil, gas, and manufacturing facilities.

Case Study: A European power plant used the 9907-205 to optimize load sharing across multiple generators, reducing downtime by 20% and improving system efficiency.

5. Competitive Comparison

The 9907-205 stands out with:

- Dual Voltage Support: Works with both 12V and 24V systems, unlike many single-voltage competitors.

- ESD Protection: 15kV rating exceeds industry standards for harsh environments.

- Multi-Protocol Compatibility: Seamless integration with Woodward’s diverse controller portfolio.

6. Selection Recommendations

- System Type: Ideal for Proact I/II systems; consider higher models (e.g., 9907-207) for complex multi-engine setups.

- Environment: Ensure temperature compatibility (-40°C to +85°C) and EMI shielding.

- Software: Pair with Woodward’s OP View™ for advanced system analysis.

7. Precautions

- Calibration: Regularly verify sensor accuracy using the built-in test mode.

- Data Backup: Always save configurations before updates to prevent parameter loss.

- Power Management: Use a stable power supply to avoid voltage spikes during programming.

Shanxi Xinyeda International Trade Co., Ltd. offers the WOODWARD 9907-205 and comprehensive automation solutions. Visit www.xydcontrol.com or contact us for sales and technical support.