Description

Product Overview

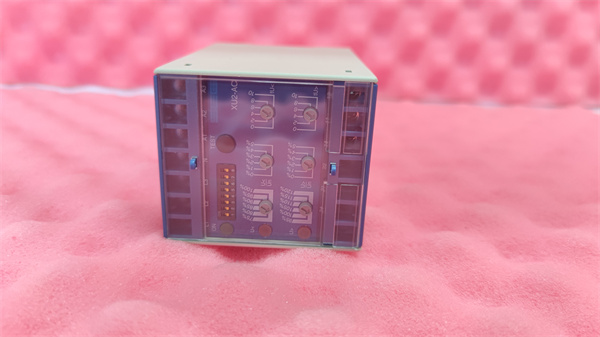

The WOODWARD XU2 – AC is a high – performance control product developed by WOODWARD, a globally recognized leader in industrial control solutions. As a significant offering in WOODWARD’s diverse product portfolio, the XU2 – AC is engineered with advanced technology to provide precise and reliable control for a wide range of industrial applications, especially those related to engine management and power – generation systems. It serves as a crucial component in optimizing system performance, ensuring stable operation, and enhancing overall efficiency across various industrial settings.

Equipped with sophisticated control algorithms and a powerful processing unit, the WOODWARD XU2 – AC enables real – time monitoring and intelligent adjustment of critical parameters. It can effectively manage aspects such as engine speed, fuel injection, and load distribution, allowing engines and power – generation units to operate at their optimal levels. Whether deployed in large – scale power plants, marine vessels navigating challenging waters, or heavy – duty mobile equipment operating in harsh environments, the XU2 – AC offers seamless control, significantly contributing to the reliability, productivity, and sustainability of industrial operations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | XU2 – AC |

| Manufacturer | WOODWARD |

| Product Type | Control Product |

| Power Supply | 100 – 240 VAC, 50/60 Hz |

| Operating Temperature Range | – 30 °C – 70 °C |

| Storage Temperature Range | – 40 °C – 85 °C |

| Input Signals | Analog (0 – 10 V, 4 – 20 mA), Digital (TTL – compatible), Frequency – based inputs |

| Output Signals | Analog (4 – 20 mA, 0 – 10 V), Pulse – Width – Modulated (PWM), Relay – based outputs |

| Communication Interfaces | CAN bus, RS – 485, Ethernet |

| Dimensions | 155 mm x 120 mm x 80 mm |

| Weight | 1.1 kg |

| Protection Level | IP65 (dust – tight and protected against water jets) |

| Processing Speed | High – performance microcontroller for rapid data processing |

woodward XU2-AC

Main Features and Advantages

Precise and Stable Control

The WOODWARD XU2 – AC excels in delivering precise and stable control over industrial processes. Its advanced control algorithms can analyze complex operating conditions in real – time and make accurate adjustments to critical parameters. In a gas – fired power – generation engine, when there are fluctuations in gas pressure or load demand, the XU2 – AC can instantly detect the changes and precisely regulate the engine speed and fuel injection. This ensures a stable power output, maximizing energy conversion efficiency and reducing emissions. The stable control also helps to extend the service life of the equipment by minimizing mechanical stress caused by inconsistent operation.

Versatile Connectivity

With support for multiple communication interfaces including CAN bus, RS – 485, and Ethernet, the XU2 – AC offers versatile connectivity options. It can seamlessly integrate with a wide variety of sensors, actuators, control systems, and higher – level management platforms. In a marine engine control system, the module can connect with sensors monitoring engine vibration, oil temperature, and exhaust gas quality, and transmit this real – time data to the ship’s bridge, on – shore monitoring centers, and other onboard systems. This enables comprehensive monitoring, remote control, and data – driven decision – making. The compatibility with different communication protocols allows for easy integration into existing industrial networks, reducing the complexity and cost of system upgrades.

Robust Design for Harsh Environments

Built to withstand harsh industrial environments, the WOODWARD XU2 – AC has an IP65 protection rating. This makes it highly resistant to dust, water jets, and vibrations, ensuring reliable operation in challenging settings such as construction sites, oil rigs, and offshore platforms. The wide operating temperature range from – 30 °C to 70 °C allows it to function effectively in various climates. The use of high – quality, industrial – grade components and a rugged construction further enhances its durability, reducing the risk of failure and minimizing maintenance requirements. This robust design ensures that the module can operate continuously, even in the most demanding industrial conditions.

User – Friendly Configuration

The XU2 – AC offers a user – friendly configuration interface. Through intuitive software tools, operators can easily customize its settings according to specific application requirements. Whether it’s adjusting control parameters for different engine models, configuring input/output signals, or setting up communication protocols, the module can be quickly configured to meet the unique needs of each application. For example, in an industrial manufacturing plant with multiple production lines powered by different engines, operators can easily adapt the XU2 – AC to the control needs of each line, saving time and effort in the installation and deployment process. This flexibility makes it suitable for a wide range of industrial scenarios.

woodward XU2-AC

Application Field

In the power – generation industry, the WOODWARD XU2 – AC is widely used for controlling diesel, gas, and hybrid – power generators in both standby and prime – power systems. It helps power plants optimize generator performance, improve fuel efficiency, and enhance grid stability. For data centers, hospitals, and other facilities that rely on uninterrupted power, the module ensures the reliable operation of backup generators, protecting critical operations from power outages. In renewable energy – integrated power plants, it can coordinate the operation of different power sources, optimizing energy production and storage.

In the marine sector, the XU2 – AC plays a crucial role in managing the operation of main engines, auxiliary engines, and generators on ships. It optimizes engine performance based on factors such as ship speed, load, sea conditions, and fuel availability, reducing fuel consumption and minimizing environmental impact. On cruise ships, it can balance power demands for propulsion, hotel services, and onboard entertainment systems. In naval vessels, its high – reliability and security features ensure the stable operation of critical power systems, enhancing mission capabilities.

For the heavy – duty mobile equipment industry, the WOODWARD XU2 – AC is used to control engine performance in construction machinery, mining trucks, and agricultural equipment. By precisely regulating engine parameters, it can enhance the productivity of equipment, reduce maintenance costs, and improve operator comfort. In the oil and gas industry, it is applied in exploration, production, and transportation equipment, ensuring reliable engine operation in harsh environments and enabling efficient resource extraction and distribution.

Related Products

- WOODWARD XU2 – DC: A related model, the XU2 – DCmay have differences in power supply type, with it being powered by direct current instead of alternating current like the XU2 – AC. It can be an alternative option for applications where a DC power supply is more suitable, while still providing similar core control capabilities.

- WOODWARD 9907 Series: This series shares some common control functions with the XU2 – ACbut is typically designed for more complex or high – performance applications. The 9907 Series may offer enhanced processing power, additional communication interfaces, or more advanced control algorithms, making it suitable for large – scale industrial setups with higher control requirements.

- WOODWARD 5464 – 461: A high – performance actuator driver, the 5464 – 461can be used in conjunction with the XU2 – AC. While the XU2 – AC generates control signals, the 5464 – 461 drives the actuators that control engine components such as fuel valves and throttle positions, forming a comprehensive engine control solution.

- WOODWARD 8290 – 100: As a communication interface module, the 8290 – 100can be integrated with the XU2 – AC to expand its communication capabilities. It enables the module to connect with a wider range of devices and systems, facilitating more complex data exchange and remote monitoring, such as interfacing with enterprise – level management systems for centralized control.

Installation and Maintenance

Pre – installation preparation: Before installing the WOODWARD XU2 – AC, carefully read the installation manual provided by WOODWARD. Ensure that the power supply voltage at the installation site is within the range of 100 – 240 VAC, 50/60 Hz. Prepare all the necessary cables and connectors for connecting the module to sensors, actuators, communication networks, and other relevant devices in the system. Select an appropriate installation location that meets the specified temperature and humidity requirements, is well – ventilated, and is free from excessive dust, moisture, and electromagnetic interference. Mount the module securely using the provided mounting brackets or screws, and make sure all connections are properly aligned and tightened according to the wiring diagram.

Maintenance recommendations: Regularly inspect the WOODWARD XU2 – AC for any signs of physical damage, such as cracks in the housing, loose connectors, or signs of overheating. Clean the module’s exterior periodically using a dry, soft cloth to remove dust and debris, especially in dusty environments. Monitor the power supply voltage regularly to ensure it remains within the specified range. Check the communication interfaces for any errors, disruptions, or data loss in data transfer. Utilize the module’s built – in diagnostic functions or the associated software tools to perform routine health checks, which can help detect potential issues like sensor malfunctions, software glitches, or hardware failures. If any abnormal behavior is detected, refer to the troubleshooting guide in the product manual or contact WOODWARD’s technical support team for assistance. Additionally, keep the module’s software updated by installing the latest firmware releases provided by WOODWARD, as these updates often include performance improvements, security enhancements, and bug fixes.

Product Guarantee

WOODWARD stands firmly behind the quality and reliability of the WOODWARD XU2 – AC. The product undergoes rigorous testing and quality control procedures during the manufacturing process to meet the highest industry standards. WOODWARD offers an extended warranty period, during which, in the event of a defect caused by faulty materials or workmanship, the company will provide free repair or replacement services. In addition to the warranty, WOODWARD’s dedicated technical support team is available 24/7 to assist customers with any installation, operation, or maintenance issues. Whether it’s providing remote diagnostic support, helping with software configuration, or offering on – site service, WOODWARD is committed to ensuring that customers can rely on the XU2 – AC for their critical control needs. This comprehensive product guarantee reflects WOODWARD’s confidence in the performance and durability of the WOODWARD XU2 – AC and its unwavering commitment to customer satisfaction.