Description

Product Overview

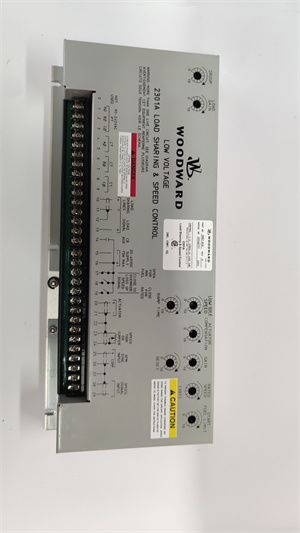

The Woodward 2301A 9907-018 is a speed – controller designed for diesel engines, gas engines, steam turbines, or gas turbines. It is a key component in the industrial automation control system, mainly used for speed and load control. Belonging to Woodward’s 2301A series, this product is positioned as a high – performance speed control device, which can meet the precise control requirements of various prime movers.

The controller can set the speed or load of the equipment according to the 4–20mA or 1–5 Vdc computer – control signal, providing users with flexible control options. It has two working modes: isochronous regulation and droop regulation, which can be applied to different working conditions, such as constant – speed control of a single – unit operation or multi – unit operation on an isolated power grid. In addition, it has functions such as synchronization or droop control, high – speed and low – speed adjustment, and override start fuel limit, which enhances its performance and application scope.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 2301A 9907 – 018 |

| Manufacturer | Woodward |

| Product Type | Speed Controller |

| Power Supply Voltage | Low – voltage type: 20 – 40Vdc; High – voltage type: 88 – 132Vac or 90 – 150Vdc6 |

| Power Consumption | Approximately 10W4 |

| Speed Range | 0 – 6000 RPM4 |

| Load Range | 0 – 100%4 |

| Operating Temperature | – 40 °C – 85 °C4 |

| Dimensions | 100 x 72 x 45 mm4 |

| Weight | 0.5 kg4 |

| Output Signal | 0 – 200mA (0 – 20mA for special applications), proportional to the fuel setting5 |

| Enclosure Material | Metal2 |

| Working Mode | Isochronous regulation, droop regulation1 |

| Certifications | CE – certified2 |

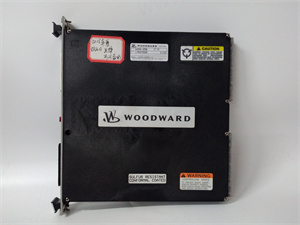

WOODWARD 2301A 9907-018

Main Features and Advantages

- Flexible Control Modes: The Woodward 2301A 9907 – 018offers two control modes, isochronous and droop regulation. Isochronous regulation is suitable for constant – speed control in single – unit or multi – unit operations on an isolated power grid, while droop regulation provides more flexible control, meeting different application requirements.

- Diverse Signal Inputs: It can accept 4–20mA or 1–5 Vdc computer – control signals, allowing for easy integration with various control systems and facilitating users to set the speed or load according to actual needs.

- Rich Additional Functions: In addition to basic speed and load control, it also has functions like synchronization or droop control, high – and low – speed adjustment, and override start fuel limit. These functions can optimize the operation of prime movers, reduce pollution and engine wear, and improve the overall efficiency of the system.

- High – precision Output: The output signal of the controller is proportional to the fuel setting required to achieve the desired speed/load, which can ensure precise control of the prime mover and make the equipment run more stably1.

- Strong Environmental Adaptability: With a metal enclosure, it has good anti – interference ability, and can work stably in harsh environments with electromagnetic interference, humidity, dust, and vibration. Its operating temperature range is wide, from – 40 °C to 85 °C, which can meet the requirements of various industrial scenarios.

Application Field

The Woodward 2301A 9907 – 018 has a wide range of application fields. In the power generation industry, it is widely used in generator systems driven by diesel engines, gas engines, etc., which can realize load sharing and speed control of multiple units, ensuring the stable operation of the power generation system and the stability of power supply.

In the oil and gas industry, it can be used for the speed control of engines and turbines in oil and gas production equipment, such as compressors and pumps, to ensure the normal operation of the equipment and improve the efficiency of oil and gas production1.

In the marine field, it is suitable for diesel engines and gas turbines on ships, which can control the speed of the main engine and auxiliary engine, and play an important role in ship navigation and power supply systems. In addition, it can also be applied to locomotives and other mobile power equipment, providing reliable speed control for them.

WOODWARD 2301A 9907-018

Related Products

- Woodward 2301A 9905: Belongs to the same 2301A series as 2301A 9907 – 018, mainly used for load sharing and speed control of generators, with similar functions but possibly different in some parameter settings.

- Woodward SPM – A Synchronizer: It can be used in conjunction with the 2301A 9907 – 018 to realize the synchronization function of the generator set, and improve the stability of the power system.

- Woodward Automatic Generator Loading Control Device: This device can cooperate with the 2301A 9907 – 018 to achieve automatic loading control of the generator, and optimize the load distribution of the generator set.

- Woodward Process Input/Output Control Device: It can be connected to the 2301A 9907 – 018, expand the input and output channels of the control system, and collect and process more process signals.

- Woodward APTL (Automatic Power Transfer Load): Used in conjunction with 2301A 9907 – 018, it is mainly responsible for the automatic transfer of power and load control, which is suitable for the load control of multiple – unit parallel operation systems.

Installation and Maintenance

Pre – installation preparation: Before installing the Woodward 2301A 9907 – 018, first, confirm the power supply voltage type. According to whether it is a high – voltage or low – voltage model, connect the corresponding 20 – 40Vdc or 88 – 132Vac (90 – 150Vdc) power supply. Then, install the speed sensor, current transformer, and potential transformer correctly to ensure accurate acquisition of speed and load signals. In addition, prepare the proportional actuator for fuel or gas metering control and connect it to the controller according to the requirements.

Maintenance recommendations: Regularly check the appearance of the Woodward 2301A 9907 – 018 to ensure that the enclosure is intact and there is no damage or deformation. Clean the dust on the controller regularly to prevent dust from affecting its heat dissipation and normal operation. Check the connection of each wire regularly to ensure that there is no looseness or disconnection. Periodically test the output signal of the controller to ensure that its accuracy meets the requirements. If any abnormal situation is found, it should be repaired or replaced in time according to the instruction manual.

Product Guarantee

Woodward provides a reliable quality guarantee for the 2301A 9907 – 018. The product has passed strict quality control and testing before leaving the factory to ensure its high – performance and stable operation. Woodward offers a certain – period warranty service. During the warranty period, if there are quality problems caused by non – human factors, free repair or replacement services will be provided. In addition, Woodward also provides professional technical support, and users can get timely help and solutions when encountering problems in use, which reflects the company’s commitment to product quality and users.