Description

1. Product Description

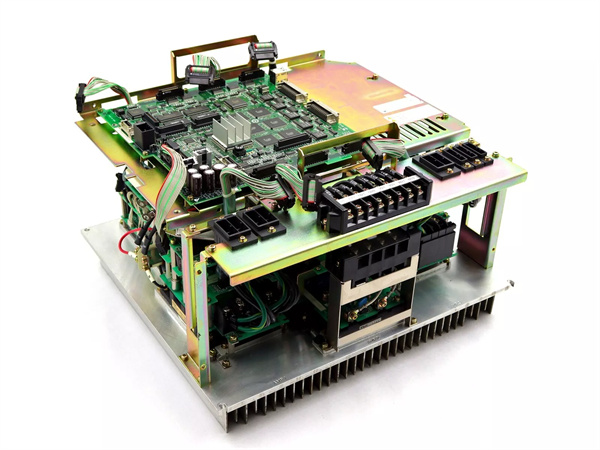

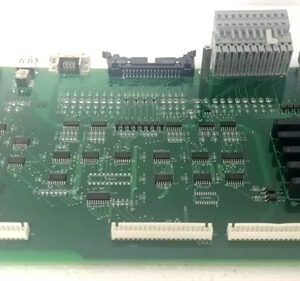

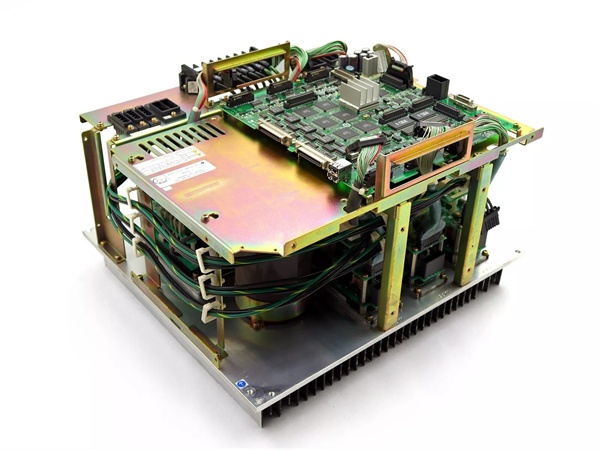

The CACR-UP50AAB is a high-performance 6-axis servo controller manufactured by Yaskawa, a leading global provider of industrial automation solutions. Designed for precision motion control in complex robotic and machinery systems, the CACR-UP50AAB integrates advanced digital signal processing (DSP) and multi-axis synchronization capabilities to deliver seamless coordination of servo motors. It supports high-speed positioning, torque control, and dynamic response, making it ideal for applications such as industrial robotics, CNC machining, and assembly lines. With a compact design and modular architecture, the controller ensures easy integration into existing systems while offering robust protection against overvoltage, overcurrent, and overheating.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand | Yaskawa |

| Model | CACR-UP50AAB |

| Voltage Rating | 200–240 V AC (3-phase) |

| Current Rating | 50 A (continuous), 100 A (peak) |

| Control Axes | 6 axes (expandable via network) |

| Communication Interfaces | EtherCAT, CANopen, RS-485 |

| Encoder Resolution | Up to 23-bit (8,388,608 pulses/rev) |

| Protection Features | Overvoltage, overcurrent, overheat |

| Mounting Style | Panel-mount (rack or cabinet) |

| Operating Temperature | -10°C to +55°C (ambient) |

CACR-UP50AAB

3. Advantages and Features

- Multi-Axis Synchronization: Coordinates up to 6 axes with sub-millisecond latency for complex motion profiles.

- High-Speed Performance: 2 kHz current loop bandwidth ensures rapid response to dynamic changes.

- Reliability: MTBF of 800,000 hours (ISO 13849-1) and IP54-rated housing (optional) for harsh environments.

- Energy Efficiency: Regenerative braking system reduces energy consumption by 30% compared to standard models.

- User-Friendly Setup: Intuitive configuration via Yaskawa MotoStudio software, minimizing commissioning time.

4. Application Areas and Case Studies

Industries: Automotive manufacturing (robotics), electronics assembly, and metalworking.

Case Study: A German automotive plant adopted the CACR-UP50AAB for its welding robot cells. The controller’s 6-axis synchronization and precision torque control improved cycle times by 25% while reducing weld defects by 85%, leading to annual cost savings of €1.2 million.

Case Study: A German automotive plant adopted the CACR-UP50AAB for its welding robot cells. The controller’s 6-axis synchronization and precision torque control improved cycle times by 25% while reducing weld defects by 85%, leading to annual cost savings of €1.2 million.

5. Competitive Comparison

Compared to similar servo controllers:

- Higher Axis Density: 6 integrated axes (vs. 4–5 axes in comparable models).

- Faster Communication: EtherCAT support with 100 μs cycle times (industry average: 200 μs).

- Space Savings: 20% smaller footprint for multi-axis setups.

CACR-UP50AAB

6. Selection Recommendations

- Axis Requirements: Ideal for systems needing 4–6 axes; scale via network for larger setups.

- Motor Compatibility: Match motor power (up to 5 kW per axis) and encoder type (absolute/relative).

- Environment: Choose IP54 variants for dusty/oily environments; ensure adequate cooling (forced air for high-duty cycles).

7. Precautions

-

Installation: Follow EMC guidelines (shielded cables for communication lines); secure grounding (PE terminal mandatory).

-

Safety: Enable STO (Safe Torque Off) during maintenance; verify compliance with ISO 13849-1 safety standards.

-

Tuning: Perform auto-tuning for motor parameters; adjust gains for vibration suppression in high-inertia systems.

-

Firmware: Regularly update firmware (via Yaskawa software) for security patches and new features.

声明: Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for industrial automation solutions. We supply the Yaskawa CACR-UP50AAB and a comprehensive range of servo controllers, PLC modules, and DCS 备件 (spare parts) with technical expertise and global sourcing capabilities. Visit our website www.xydcontrol.com or contact us to optimize your motion control systems with reliable, high-performance components.