Description

Product Specification: Yaskawa JANCD-MM13B Memory/Control Module

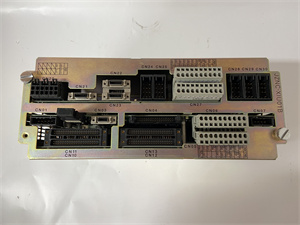

The Yaskawa JANCD-MM13B is a high-performance module designed for industrial automation and robotics systems, specifically optimized for Yaskawa’s Motoman robot controllers. This module combines memory storage and motion control capabilities, making it a critical component for applications requiring precision, reliability, and scalability.

1. Product Description

The JANCD-MM13B is a compact, dual-function module that integrates memory storage and motion control in Yaskawa robotic systems. Key features include:

- Dual Functionality: Serves as both a memory module for program storage and a motion control card for real-time axis coordination.

- High-Speed Processing: Supports fast data transfer and synchronization for complex robotic tasks.

- Compatibility: Works seamlessly with Yaskawa’s MRC (Motion Robot Controller) series, including models like the JANCD-MCP02B-1.

- Modular Design: Enables firmware updates and expansions to adapt to evolving system requirements.

- Space-Saving Layout: Ideal for integration into tight industrial environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 24V DC ±10% |

| Memory Capacity | 128 MB (expandable via slots) |

| Communication Interfaces | Ethernet, RS-485, CANopen |

| Operating Temperature | -10°C to +60°C |

| Weight | ~0.8 kg |

| Certifications | CE, UL, RoHS |

3. Advantages and Features

- Cost-Effective Integration: Combines memory and motion control into a single module, reducing hardware costs and complexity.

- Reliability: Industrial-grade components with ESD protection and a MTBF of over 100,000 hours.

- Energy Efficiency: Low power consumption (<40W) for reduced operational costs.

- Flexibility: Supports up to 8 axes of motion control for multi-robot setups.

4. Application Areas and Cases

- Automotive Manufacturing: Used in welding, painting, and assembly lines for precise robot synchronization.

- Electronics Assembly: Coordinates pick-and-place operations in PCB manufacturing.

- Case Study: A leading automotive plant improved cycle times by 20% using JANCD-MM13B to synchronize dual-arm robots for engine block assembly.

5. Competitor Comparison

The JANCD-MM13B differentiates itself with:

- Integrated Architecture: Eliminates the need for separate memory and motion control modules.

- Advanced Compatibility: Native support for Yaskawa’s proprietary robot programming languages (e.g., INFORM III).

- Long-Term Support: Backed by Yaskawa’s global service network for firmware updates and technical assistance.

6. Selection Recommendations

- System Size: Ideal for mid-to-large robotic systems requiring 4–8 axes of control.

- Memory Needs: Choose the JANCD-MM13B if your application requires expandable storage beyond 128 MB.

- Budget: Offers a balance between performance and cost compared to higher-end modular solutions.

7. Precautions

-

ESD Handling: Use anti-static equipment during installation to avoid component damage.

-

Firmware Updates: Regularly update firmware to access new features and security patches.

-

Cooling Requirements: Ensure adequate ventilation in high-temperature environments.

-

Wiring Compliance: Follow Yaskawa’s guidelines to prevent signal interference.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner for [Yaskawa JANCD-MM13B] and other industrial automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.