Description

Product Overview

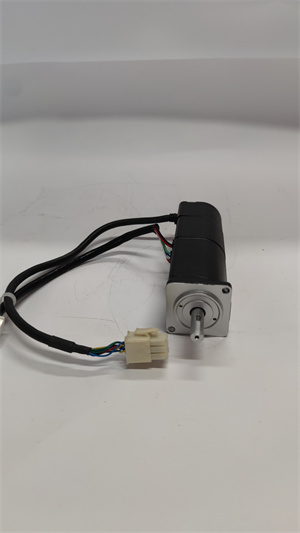

The YASKAWA SGM – 01A314B is a high – performance servo motor developed by YASKAWA, a renowned global leader in industrial automation and motion control solutions. As a key component in YASKAWA’s extensive servo product portfolio, the SGM – 01A314B is designed with advanced technology to offer precise, reliable, and efficient motion control for a wide range of industrial applications. It serves as a critical element in enhancing the performance of automated production lines, robotic systems, and other motion – intensive equipment, ensuring smooth operation, accurate positioning, and overall productivity improvement.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | SGM – 01A314B |

| Manufacturer | YASKAWA |

| Product Type | Servo Motor |

| Rated Output | 0.1 kW |

| Rated Torque | 0.32 N·m |

| Rated Speed | 3000 r/min |

| Max. Speed | 5000 r/min |

| Continuous Current | 1.0 A |

| Peak Current (30 s) | 3.0 A |

| Encoder Type | Absolute Encoder, Resolution: 17 – bit (131072 pulses/rev) |

| Power Supply | Three – phase AC 200 – 240 V, 50/60 Hz |

| Operating Temperature Range | 0 °C – 40 °C |

| Storage Temperature Range | – 20 °C – 65 °C |

| Dimensions | (W x H x D) 40 mm x 95 mm x 101.5 mm |

| Weight | 0.65 kg |

| Protection Level | IP65 (dust – tight and protected against water jets) |

YASKAWA SGM-01A314B

Main Features and Advantages

High – precision Motion Control

The YASKAWA SGM – 01A314B excels in providing high – precision motion control. Thanks to its 17 – bit absolute encoder, it can achieve extremely accurate positioning with a resolution of 131072 pulses per revolution. In applications such as the assembly of micro – electronic components, where even the slightest deviation can lead to product defects, this servo motor ensures that robotic arms place components with utmost precision. The accurate feedback from the encoder enables real – time adjustments, allowing for smooth and precise movements, which significantly improves the quality and yield rate of production processes that demand high accuracy.

Compact and Lightweight Design

With its compact dimensions of 40 mm x 95 mm x 101.5 mm and a weight of only 0.65 kg, the SGM – 01A314B features a highly space – saving and lightweight design. This makes it an ideal choice for applications where installation space is limited, such as in small – scale automated devices, medical equipment, or the internal mechanisms of precision instruments. Its small footprint allows for easy integration into existing systems without requiring major modifications to the equipment’s structure, saving both space and installation costs. Despite its small size, it still delivers reliable performance, maintaining high torque and speed capabilities, making it suitable for a variety of applications that need to balance compactness with functionality.

High – performance and Efficiency

Equipped with advanced motor technology and optimized internal components, the SGM – 01A314B offers excellent performance. It can deliver a rated torque of 0.32 N·m even at low speeds, providing sufficient driving force for a wide range of mechanical systems. The motor’s high – efficiency design reduces energy losses during operation, minimizing power consumption. In industrial environments where equipment operates continuously, this energy – saving feature not only helps to lower operational costs but also contributes to a more sustainable and environmentally friendly production process. The motor’s ability to maintain stable performance across different operating conditions ensures reliable operation and reduces the likelihood of unexpected failures.

Robust and Durable Construction

Built with high – quality materials and a rugged design, the YASKAWA SGM – 01A314B is engineered to withstand harsh industrial environments. The IP65 protection level makes it resistant to dust, water jets, and vibrations, enabling it to operate reliably in challenging settings like factories with high levels of dust, outdoor equipment, or near water – based production processes. The use of reliable components and strict manufacturing quality control processes further enhances its durability, reducing the risk of mechanical failures and minimizing maintenance requirements. This robust construction allows industrial users to rely on the SGM – 01A314B for continuous and stable operation, enhancing the overall reliability of their automated systems and reducing downtime.

YASKAWA SGM-01A314B

Application Field

In the electronics manufacturing industry, the YASKAWA SGM – 01A314B is widely used in equipment such as pick – and – place machines, semiconductor bonding machines, and precision inspection systems. Its high – precision motion control ensures accurate placement of tiny electronic components, precise bonding of semiconductor chips, and accurate movement of inspection probes, contributing to the production of high – quality electronic products with high precision and reliability.

For the medical equipment field, its compact and lightweight design, combined with high – precision motion control, makes it suitable for use in devices like surgical robots, medical imaging equipment with moving parts, and laboratory automation systems. In surgical robots, the SGM – 01A314B enables precise and stable movements of robotic arms, assisting surgeons in performing minimally invasive surgeries with greater accuracy and control. In laboratory automation, it controls the movement of sample handling mechanisms, ensuring accurate and repeatable operations in processes such as sample dispensing, mixing, and analysis.

In the small – scale automation and robotics sector, the SGM – 01A314B is applied in applications like desktop robotic arms for educational purposes, small – scale assembly robots for prototyping, and automated guided vehicles (AGVs) in limited – space environments. Its compact size allows for easy integration into these small – scale systems, while its high – performance and precise control capabilities ensure smooth and efficient operation, making it a valuable component for various innovative automation and robotic projects.

Related Products

- YASKAWA SGM – 02A314B: This related model has a higher rated output of 0.2 kW compared to the SGM – 01A314B. It offers increased torque and power capabilities, making it suitable for applications that require more driving force, such as in larger – scale robotic arms or heavier – duty automated equipment. While sharing similar features like encoder type and protection level, the SGM – 02A314B provides an option for users who need a step – up in performance while still maintaining compatibility with YASKAWA’s servo drive systems and control architectures.

- YASKAWA Sigma – 7 Series Servo Drives: These servo drives are designed to work in tandem with the SGM – 01A314B. The Sigma – 7 Series servo drives receive control signals and power the servo motor, enabling precise control over its speed, position, and torque. They are equipped with advanced control algorithms and communication interfaces, allowing for seamless integration with programmable logic controllers (PLCs), human – machine interfaces (HMIs), and other automation devices. Together, the SGM – 01A314B and Sigma – 7 Series servo drives form a comprehensive servo system that is widely used in various industrial automation applications, providing high – performance and reliable motion control.

- YASKAWA MP3300iec Motion Controller: The MP3300iec Motion Controller can be used in combination with the SGM – 01A314B to create more advanced automation systems. It provides higher – level control functions, such as programming complex motion paths, synchronizing multiple servo motors, and integrating with other industrial control devices. In applications where multiple axes of motion need to be coordinated, like in multi – axis robotic arms or complex automated production lines, the MP3300iec Motion Controller sends precise control commands to the servo drive of the SGM – 01A314B, enabling accurate and coordinated movement of the motor, enhancing the overall functionality and performance of the automation system.

- YASKAWA JAPMC – CP2230 – E: As a programmable controller, the JAPMC – CP2230 – E can communicate with the servo drive associated with the SGM – 01A314B to create an integrated automation solution. The controller sends control commands based on the overall process requirements, such as starting, stopping, and adjusting the speed and position of the servo motor. It can be programmed using various languages like ladder diagram, structured text, and function block diagram, providing flexibility in implementing different control strategies for industrial processes. This integration allows for the implementation of sophisticated control logic, enabling the automation of complex production processes and improving the efficiency and productivity of industrial operations.

Installation and Maintenance

Pre – installation preparation: Before installing the YASKAWA SGM – 01A314B, carefully read the detailed installation manual provided by YASKAWA. Ensure that the power supply at the installation site is a three – phase AC within the range of 200 – 240 V, 50/60 Hz, and that it is properly grounded. Prepare all the necessary cables, including power cables, encoder cables, and any additional communication cables if required. Select an appropriate installation location that meets the temperature and humidity requirements and is free from excessive dust, moisture, and strong electromagnetic interference. Mount the servo motor securely using the provided mounting brackets or screws, making sure to follow the correct alignment and torque specifications to prevent vibration and ensure smooth operation. Pay special attention to the connection of the encoder cable to ensure accurate position feedback.

Maintenance recommendations: Regularly inspect the YASKAWA SGM – 01A314B for any signs of physical damage, such as cracks in the housing, loose connectors, or abnormal noise during operation. Clean the exterior of the motor periodically using a dry, soft cloth to remove dust and debris, especially in dusty environments. Monitor the operating temperature of the motor during operation to ensure it remains within the specified range. Check the encoder connection regularly to ensure accurate position feedback; any loose or damaged connections can lead to inaccurate motion control. Utilize the diagnostic functions of the associated servo drive or control system to perform routine health checks on the motor, which can help detect potential issues like bearing wear, winding insulation degradation, or encoder malfunctions. If any abnormal behavior is detected, refer to the troubleshooting guide in the product manual or contact YASKAWA’s technical support team for assistance. Additionally, follow the recommended lubrication schedule if applicable to maintain the smooth operation of the motor’s internal components. Keep the firmware of the associated servo drive updated by installing the latest releases provided by YASKAWA, as these updates often include performance improvements, security enhancements, and bug fixes that can also benefit the operation of the SGM – 01A314B.

Product Guarantee

YASKAWA stands firmly behind the quality and reliability of the YASKAWA SGM – 01A314B. The product undergoes strict and comprehensive testing and quality control procedures during the manufacturing process to meet and exceed international industry standards. YASKAWA offers an extended warranty period, during which, in the event of a defect caused by faulty materials or workmanship, the company will provide free repair or replacement services. In addition to the warranty, YASKAWA’s professional technical support team is available to assist customers with any installation, operation, or maintenance issues. Whether it’s providing remote diagnostic support, helping with system integration, or offering on – site service, YASKAWA is committed to ensuring that customers can rely on the SGM – 01A314B for their critical industrial motion control needs. This comprehensive product guarantee reflects YASKAWA’s confidence in the performance and durability of the YASKAWA SGM – 01A314B and its unwavering commitment to customer satisfaction.