Description

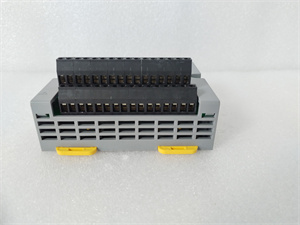

YOKOGAWA A1BA4D-05 Terminal Board for Analog I/O

1. Product Description

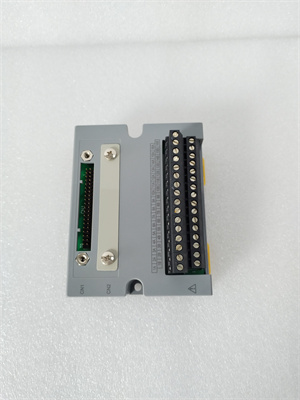

The YOKOGAWA A1BA4D-05 is a DIN rail-mounted terminal board designed for analog signal connectivity in Yokogawa’s distributed control systems (DCS) and field input/output (FIO) platforms. Engineered for industrial automation, the A1BA4D-05 supports single and dual-redundant configurations, offering 16-channel ×1 or 8-channel ×1 signal termination for seamless integration with Yokogawa’s I/O modules (e.g., Centum CS/VP, ProSafe-RS). Its pressure clamp terminals enable secure connections to field devices (sensors, transmitters) via direct wiring, KS cable adapters, or customer-furnished MIL connectors. The module features a compact design (263 × 138 × 88 mm) and lightweight construction (0.3 kg), ensuring easy installation in space-constrained environments. With no explosion protection (suffix -05), it is ideal for non-hazardous zones, providing reliable signal routing for process control, data acquisition, and monitoring applications.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | A1BA4D-05 |

| Brand | YOKOGAWA |

| Product Type | Analog Terminal Board (FIO System) |

| Configuration | Single/dual-redundant; 16-channel ×1 or 8-channel ×1 |

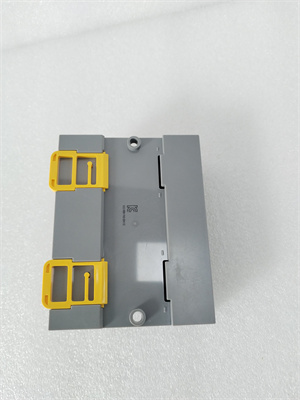

| Mounting Type | DIN rail (35 mm) |

| Signal Connections | Pressure clamp terminals; KS cable adapter; MIL connector (customer-furnished) |

| Weight | 0.3 kg (shipping weight: 1.5 kg) |

| Dimensions (W×H×D) | 263 mm × 138 mm × 88 mm |

| Suffix Code | -05 (basic type, no explosion protection) |

| Compatibility | Yokogawa DCS/FIO systems (Centum CS/VP, ProSafe-RS) |

| Environment | Operating: -10°C to +60°C; Storage: -20°C to +70°C (non-condensing) |

A1BA4D-05

3. Advantages and Features

- Flexible Signal Routing: Supports multiple connection methods (terminals, KS cables, MIL connectors) for versatile field device integration.

- Redundancy Support: Dedicated terminal blocks for dual-redundant configurations, enhancing system reliability.

- Space-Saving Design: Compact DIN rail mount reduces panel space requirements in control cabinets.

- Easy Maintenance: Modular design allows quick replacement without disrupting system operations.

- Cost-Effective: Basic configuration (no explosion protection) suits non-hazardous industrial settings.

4. Application Areas and Use Cases

- Industries: Manufacturing, energy, water treatment, chemical processing.

- Scenarios: Analog signal termination for DCS I/O modules, field device wiring, redundant system setups.

- Use Case: A manufacturing plant integrated 20 A1BA4D-05 boards to manage analog signals (4–20 mA) from temperature and pressure sensors in its Centum VP DCS, achieving 99.9% signal integrity and simplified maintenance.

5. Competitor Comparison

Compared to similar terminal boards:

- Channel Density: 16-channel ×1 configuration (vs. 8–12 channels in alternatives) for high-density applications.

- Redundancy Flexibility: Native dual-redundant support (no additional adapters required), reducing installation complexity.

- Yokogawa Ecosystem Fit: Pre-engineered compatibility with Yokogawa’s I/O modules and diagnostics, minimizing commissioning time.

A1BA4D-05

6. Selection Recommendations

- Channel Requirements: Choose 16-channel ×1 (high-density) or 8-channel ×1 (sparse) based on system I/O needs.

- Environment: Suitable for non-hazardous zones (no explosion protection); use alternative models (e.g., A1BA4D-XX with explosion protection) for hazardous areas.

- Mounting Space: Ensure DIN rail availability (35 mm) and panel dimensions (263 × 138 mm) fit the enclosure.

- Redundancy Needs: Opt for dual-redundant configuration (with compatible I/O modules) for critical processes.

7. Precautions

- Installation: Torque terminals to 0.5–0.8 N·m to prevent loose connections; follow Yokogawa’s wiring diagrams.

- Signal Integrity: Use shielded cables for analog signals to minimize interference; avoid mixing power and signal wiring.

- Maintenance: Inspect terminals annually for corrosion or looseness; replace worn terminals promptly.

- Compatibility: Verify compatibility with Yokogawa I/O modules (e.g., AAD11, AAM11) before deployment.

声明: Shanxi Xinyeda International Trade Co., Ltd. specializes in YOKOGAWA automation 备件,including the A1BA4D-05 terminal board. We offer 100% genuine products, 12-month warranties, and global logistics. Explore our inventory at www.xydcontrol.com or contact us for technical support and competitive pricing.