Description

1. Product Description

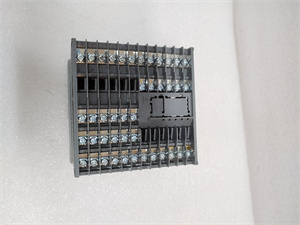

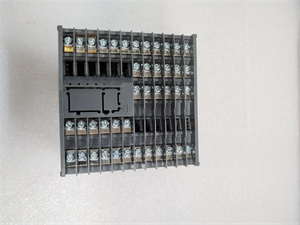

The Yokogawa UP55A-001-11-00 is a 1/4 DIN-sized program controller designed for precision automation in industrial processes. Built for versatility, the UP55A-001-11-00 offers up to 30 program patterns and 300 segments (expandable to 99 patterns/600 segments with optional features), enabling complex sequence control for applications like heat treatment, sterilization, and manufacturing. Its core functions include ladder sequence control, fuzzy logic algorithms, and simultaneous monitoring of 8 PV events, 16 time events, and 8 alarms. The controller supports multiple communication protocols (Ethernet Modbus/TCP, RS-485 Modbus/RTU) and features a compact 65-mm depth design with an intuitive 14-segment color LCD display for real-time parameter tracking. With built-in reliability features like a 3-year warranty and IP66-rated front panel, the UP55A-001-11-00 balances performance and durability for demanding industrial environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 100–240 V AC (50/60 Hz) |

| Dimensions | 1/4 DIN (96 × 96 mm), 65 mm depth |

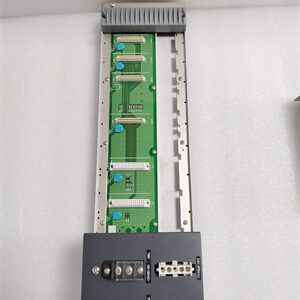

| Input Types | 8 digital inputs (DI), 8 digital outputs (DO) |

| Communication | Ethernet (Modbus/TCP), RS-485 (Modbus/RTU, Peer-to-Peer) |

| Display | 14-segment color LCD with scrolling text |

| Control Functions | PID, fuzzy logic, ladder sequence control |

| Program Capacity | 30 patterns (300 segments) – expandable with optional features |

| Environmental Ratings | NEMA 4/IP66 (front panel), RoHS/WEEE compliant |

| Warranty | 3 years (from factory shipment) |

YOKOGAWA UP55A-001-11-00

3. Advantages and Features

- Advanced Control Capabilities: Integrates ladder sequence control (replacing standalone PLCs) and fuzzy logic for adaptive process tuning.

- Reliability: IP66-rated front panel resists dust and water ingress (hose-down test certified).

- Ease of Use: Multilingual support (English, Spanish, French, German), programmable function keys, and default parameter presets.

- Network Flexibility: Supports Ethernet and RS-485 for seamless integration into industrial networks (e.g., Profibus-DP, CC-Link via options).

- Compact Design: 65-mm depth saves space in control panels while maintaining full functionality.

- Longevity: 3-year warranty surpasses industry standards for extended operational confidence.

4. Application Areas and Use Cases

Industries: Manufacturing (heat treatment), energy (process control), pharmaceuticals (sterilization), and food processing.

Use Case: A Japanese steel plant (Muroran Plant) deployed the UP55A-001-11-00 for heat treatment furnace control, achieving precise temperature profiling across 30 program patterns. The ladder sequence control automated auxiliary machinery (e.g., fans, valves), reducing manual intervention by 40% and improving process repeatability.

Use Case: A Japanese steel plant (Muroran Plant) deployed the UP55A-001-11-00 for heat treatment furnace control, achieving precise temperature profiling across 30 program patterns. The ladder sequence control automated auxiliary machinery (e.g., fans, valves), reducing manual intervention by 40% and improving process repeatability.

5. Competitive Comparison

Compared to similar DIN-sized controllers, the UP55A-001-11-00 distinguishes itself with:

- Integrated Ladder Logic: Eliminates the need for a separate PLC, reducing system complexity and costs.

- Expansive Program Capacity: Up to 600 segments (with options) vs. typical 200–300 segments in 竞品.

- Robust Networking: Native Ethernet support (Modbus/TCP) and optional open networks (Profibus-DP) for scalable connectivity.

- User Interface: Large color LCD with scrolling text vs. monochrome displays in comparable models.

YOKOGAWA UP55A-001-11-00

6. Selection Recommendations

- Compatibility: Ensure compatibility with existing systems (e.g., Modbus protocols, input/output requirements).

- Installation Environment: Verify IP66 rating suits your environment (e.g., wet or dusty settings).

- Program Complexity: Choose optional features (e.g., expanded segments, additional I/O) for complex sequences.

- Budget: Balance advanced features (e.g., Ethernet) with cost—base models offer core functionality at competitive prices.

7. Precautions

- Power Supply: Ensure voltage matches 100–240 V AC to avoid damage.

- Wiring: Follow terminal diagrams (refer to the operation manual) for correct DI/DO and communication connections.

- Maintenance: Schedule annual checks for terminal tightness and display functionality.

- Safety: Do not use in explosive atmospheres. Install protective circuits for lightning and surge protection (user responsibility).

声明:

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for Yokogawa UP55A-001-11-00 and other automation spare parts. We provide sales, technical support, and customized solutions. Visit our website www.xydcontrol.com or contact us for expert assistance.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for Yokogawa UP55A-001-11-00 and other automation spare parts. We provide sales, technical support, and customized solutions. Visit our website www.xydcontrol.com or contact us for expert assistance.