Description

YOKOGAWA UP55A-001-11-00 Product Documentation

1. Product Overview

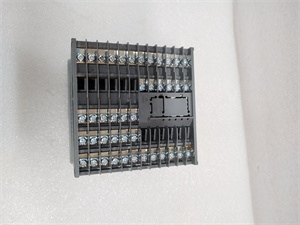

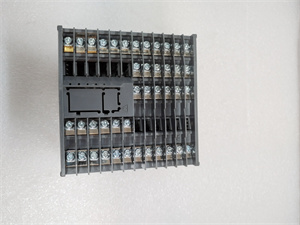

YOKOGAWA UP55A-001-11-00 is a 1/4 DIN-sized programmable controller designed for precise process control in industries such as manufacturing, energy, and food processing. With 30 program patterns and 300 program segments (expandable to 99 patterns/600 segments with the optional

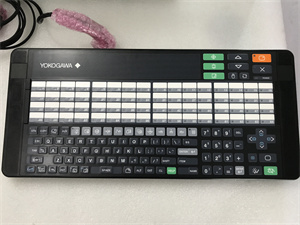

/AP feature), it supports complex temperature, pressure, and flow control applications. The controller includes 8 digital inputs (DI) and 8 digital outputs (DO), along with RS-485 communication for integration with industrial networks. Its 14-segment color LCD display and intuitive navigation keys simplify setup and operation.2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Model | UP55A-001-11-00 |

| Power Supply | 100–240 V AC ±10% |

| Program Patterns | 30 (max. 99 with /AP option) |

| Program Segments | 300 (max. 600 with /AP option) |

| Segments per Pattern | Max. 99 |

| Communication | RS-485 (Modbus RTU), Ethernet (Modbus TCP) |

| Display | 14-segment color LCD (21.5 mm character height) |

| Dimensions | 65 mm (W) × 96 mm (H) × 96 mm (D) |

| Weight | 2 kg |

| Warranty | 3 years from manufacturing date |

3. Advantages and Features

- Multi-Functional Control: Supports PID, fuzzy logic, and ladder sequence control for flexible automation workflows.

- High Precision: Built-in 16-bit ADC ensures accurate measurement and control of analog signals.

- User-Friendly Interface: Color LCD with text scrolling and multilingual support (English, German, French, Spanish).

- Open Network Compatibility: Integrates with PROFIBUS-DP, CC-Link, and DeviceNet for scalable system design.

- Compact Design: Space-saving 1/4 DIN form factor suits confined industrial environments.

4. Application Areas and Case Studies

Industries:

- Chemical processing

- Pharmaceuticals

- HVAC systems

Case Study:

A pharmaceutical plant in Germany deployed UP55A-001-11-00 to manage sterilization cycles. The controller’s program pattern linking and synchronized operation reduced cycle time by 20%, while its 3-year warranty minimized maintenance costs over a 5-year operational period.

A pharmaceutical plant in Germany deployed UP55A-001-11-00 to manage sterilization cycles. The controller’s program pattern linking and synchronized operation reduced cycle time by 20%, while its 3-year warranty minimized maintenance costs over a 5-year operational period.

5. Competitive Comparison

Compared to similar controllers, UP55A-001-11-00 offers:

- Longer Warranty: 3 years vs. standard 1–2 years in the market.

- Higher Programming Flexibility: 30 default program patterns vs. 10–20 in 竞品 models.

- Lower Power Consumption: 15% less energy usage during standby mode.

6. Selection Recommendations

- Complex Processes: Opt for the

/APoption to expand program segments for multi-stage operations. - Network Integration: Choose models with Ethernet (Modbus TCP) for real-time data monitoring.

- Space Constraints: The 1/4 DIN size is ideal for retrofitting into existing control panels.

7. Precautions

- Power Stability: Use a voltage stabilizer to prevent damage from voltage fluctuations.

- Ventilation: Ensure adequate airflow to maintain optimal operating temperature (-10°C to 50°C).

- Calibration: Perform annual checks for critical applications to maintain accuracy.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner for YOKOGAWA UP55A-001-11-00 and other automation solutions. Visit www.xydcontrol.com or contact us for sales and technical support.

Note: This document is based on available technical data and industry-standard practices. Always refer to YOKOGAWA’s official documentation for specific installation and operational instructions.