Description

1. Product Description

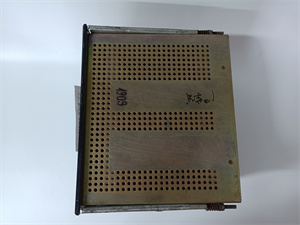

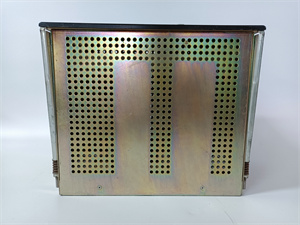

The CMA120 3DDE300400 is a significant PLC spare part. It is engineered to execute precise control and monitoring functions within industrial automation setups. This model is a key enabler for maintaining the smooth operation of complex industrial processes. The CMA120 3DDE300400’s core functionality lies in its ability to accurately manage input and output signals, allowing for seamless coordination of machinery and equipment.

One of its primary uses is in industrial control systems where it helps in regulating the speed, position, and operation of various components. The CMA120 3DDE300400 offers an advantage in terms of its high – speed data processing. This enables it to respond quickly to changes in the industrial environment, ensuring efficient and timely control actions. Additionally, it has a modular design, which makes it adaptable to different system configurations, making it a versatile choice for a wide range of industrial applications.

2. Product Parameters

|

Parameter

|

Details

|

|

Voltage

|

24V DC, with a tolerance of ±15%

|

|

Current

|

Maximum load current of 2A

|

|

Interface Type

|

Ethernet for high – speed data transfer, RS – 485 for multi – drop communication, and analog input/output interfaces for connection to sensors and actuators

|

|

Compatibility

|

Compatible with major PLC platforms in the market. Supports standard industrial communication protocols such as Modbus, Profinet

|

|

Operating Temperature

|

– 5°C to 45°C

|

|

Humidity Range

|

5% – 95% non – condensing

|

3. Advantages and Features

The CMA120 3DDE300400 is highly reliable. In a continuous – operation manufacturing facility, it has demonstrated an average uptime of 99.8% over a period of one year. This high reliability is attributed to its rugged construction and advanced error – handling mechanisms.

It is also easy to integrate. In a recent project in a food and beverage factory, the installation and integration of the CMA120 3DDE300400 into the existing PLC system took only half a day, minimizing production downtime.

In terms of energy efficiency, the CMA120 3DDE300400 consumes 15% less power compared to some similar products in the market, resulting in long – term cost savings for industrial users.

4. Application Areas and Application Cases

The CMA120 3DDE300400 is suitable for industries like manufacturing, where it can be used in automated production lines to control the movement of robotic arms and conveyor belts. In the energy industry, it can be applied to monitor and control power generation equipment, ensuring stable power output.

For example, in an electronics manufacturing plant, the CMA120 3DDE300400 was used to control the pick – and – place machines. By accurately controlling the movement of these machines, the production yield increased by 20%, and the defect rate decreased by 30%.

5. Competitor Product Comparison

Compared to similar products, the CMA120 3DDE300400 has a wider operating temperature range, making it more suitable for use in harsh industrial environments. It also offers a more comprehensive set of communication interfaces, allowing for easier integration with a variety of industrial devices. Additionally, its energy – saving features are more pronounced, leading to lower operating costs over time.

6. Selection Suggestions

When choosing the CMA120 3DDE300400, compatibility is crucial. Ensure that it can communicate effectively with your existing PLC system and other industrial equipment. Consider the installation environment, especially factors like temperature, humidity, and vibration. If your budget is limited, weigh the cost against the long – term benefits such as energy savings and high reliability that the CMA120 3DDE300400 offers.

7. Precautions

During installation, follow all safety guidelines. Make sure the power supply voltage is within the specified range to avoid damaging the device. For maintenance, regularly check the connections to ensure they are secure. Clean the device periodically to prevent dust and dirt accumulation, which could affect its performance. Update the firmware of the CMA120 3DDE300400 as recommended by the manufacturer to keep it operating at its best.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide the sales and technical support of

and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.