Description

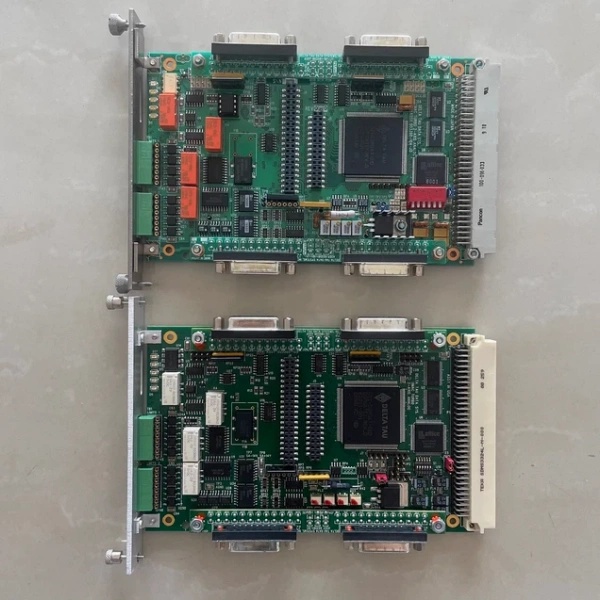

ACC-24E2A

- •

Model Number: ACC-24E2A - •

Manufacturer: Delta Tau Data Systems - •

Product Type: Turbo PMAC2 Accessory Board - •

Number of Axes: 2 independent servo channels - •

Analog Output: ±10V differential, 16-bit resolution - •

Encoder Inputs: 4 channels per axis (A, B, C, D) - •

Encoder Resolution: 24-bit position resolution - •

Maximum Count Rate: 20 MHz - •

Feedback Types: Incremental encoder, absolute serial encoder, resolver - •

Servo Update Rate: Configurable up to 44 kHz - •

Communication Interface: Parallel bus to Turbo PMAC2 CPU - •

Power Supply: +5V DC from host controller - •

Operating Temperature: 0°C to 60°C - •

Storage Temperature: -40°C to 85°C - •

Connector Type: 50-pin high-density D-sub - •

Isolation: 500V optical isolation on encoder inputs ACC-24E2A