Description

Product Overview

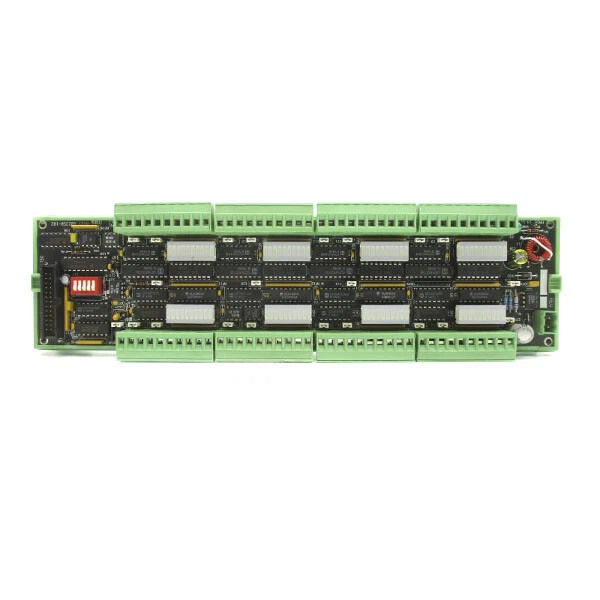

The DELTA TAU 602226-102 is a high-precision servo drive interface module designed for Delta Tau’s Power PMAC motion control platform, enabling nanosecond-level synchronization of multi-axis industrial automation systems. This critical component bridges Power PMAC controllers with amplifiers and feedback devices, executing real-time trajectory planning and closed-loop control for applications demanding micron-level accuracy. The 602226-102 supports dual-channel SERCOS III, EtherCAT, or PWM interfaces while processing 32-bit position/velocity data at 4 kHz update rates. Its FPGA-based architecture implements hardware-optimized control algorithms – including PID, notch filtering, and feedforward compensation – reducing servo lag by up to 50% compared to software-based solutions. Engineered for harsh environments, the DELTA TAU 602226-102 operates at -10°C to 60°C with conformal coating for humidity resistance. For semiconductor manufacturing, robotics, and precision test systems, this module delivers uncompromising performance in synchronizing up to 32 axes with jitter below 100 ns.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 602226-102 |

| Manufacturer | DELTA TAU |

| Product Type | Servo Interface Module |

| Control Interfaces | SERCOS III, EtherCAT, PWM/±10V analog |

| Axis Capacity | Up to 32 axes (cascadable) |

| Update Rate | 4 kHz (position loop) |

| Feedback Resolution | 32-bit encoder/counter |

| Communication Latency | <100 ns jitter |

| Control Algorithms | PID + velocity/acceleration feedforward, notch filter |

| FPGA Resources | 150K logic elements, 4.5 Mb RAM |

| Isolation | 1500V AC (field-to-controller) |

| Operating Temperature | -10°C to +60°C |

| Power Requirements | 5V DC ±5% (1.2A max) |

| Connector Types | HD-68 (I/O), SFP (fiber), RJ45 (EtherCAT) |

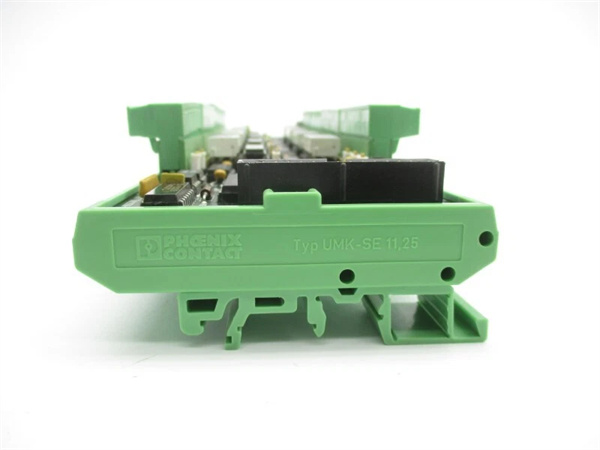

| Dimensions | 110 x 23 x 150 mm (LxWxH) |

DELTA TAU 602226-102

Main Features and Advantages

Deterministic Motion Control: Hardware-accelerated trajectory generation in the 602226-102 eliminates CPU load spikes, maintaining <1µs axis synchronization even during complex contouring operations.

Multi-Protocol Flexibility: Seamlessly interface with third-party drives via SERCOS III, EtherCAT, or legacy analog/PWM signals without external converters – critical for retrofit applications.

Advanced Vibration Suppression: Onboard FPGA implements 8-stage adaptive notch filters and friction compensation algorithms, reducing settling time by 40% in high-precision stages.

Diagnostic Granularity: Real-time capture of servo error, torque saturation, and following error with 16-bit resolution at 10 kHz sampling – enabling predictive maintenance for critical axes.

Cyber-Physical Integration: Secure boot with signed firmware ensures control integrity. Timestamped data streams synchronize with Power PMAC’s data recorder for comprehensive motion analysis.

DELTA TAU 602226-102

Application Field

The DELTA TAU 602226-102 excels in ultra-precision motion systems:

Semiconductor Manufacturing: Synchronizes wafer steppers and wire bonders with <100nm positioning repeatability

Photonics Alignment: Controls 6-axis hexapods for laser collimation with 0.0001° resolution

Robotic Machining: Implements adaptive toolpath control for aerospace composite trimming

Medical Device Assembly: Coordinates micro-dispensing robots with 10ms cycle times

Test Simulation: Replicates earthquake profiles on multi-axis shake tables with 0.01g accuracy

Related Products

ACC-24E3: 8-axis EtherCAT interface module

PMAC2 CPU: Power PMAC motion controller

ACC-84E: 4-channel analog servo interface

OPT-416: Fiber optic SERCOS III hub

ACC-58E: High-density I/O expansion

AKM2G: Kollmorgen servo motors

TURBO PMAC3: Compact motion controller

Installation and Maintenance

Pre-installation preparation: Verify controller firmware compatibility (Power PMAC Suite 4.5+). Use shielded twisted-pair cables for analog interfaces with ground termination at drive end only. Allocate 25mm clearance for heat dissipation.

Maintenance recommendations: Monitor FPGA temperature via PMAC IDE software monthly. Recalibrate analog offset/gain annually using metrology-grade voltage reference. Replace cooling fans after 50,000 hours in 24/7 operation.

Product Guarantee

DELTA TAU provides a 36-month warranty covering defects in materials and workmanship. Includes lifetime firmware updates and 10-year repair support. All 602226-102 modules undergo 72-hour burn-in testing with thermal cycling and motion profile validation. Global technical support offers 24/7 critical failure response with 8-hour escalation for semiconductor production lines.