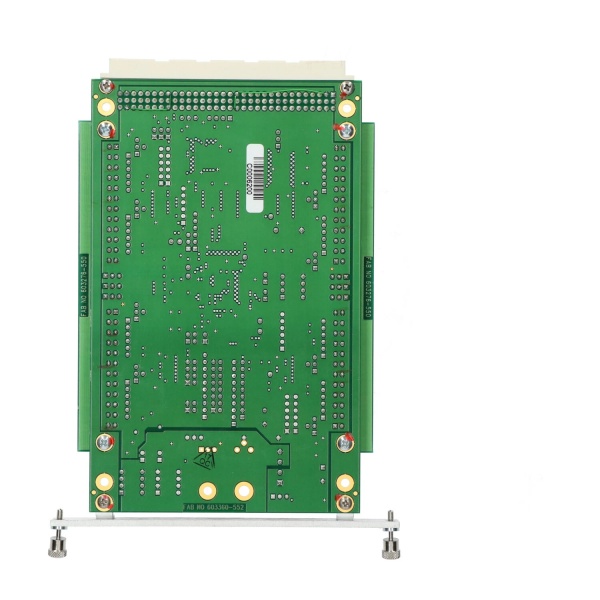

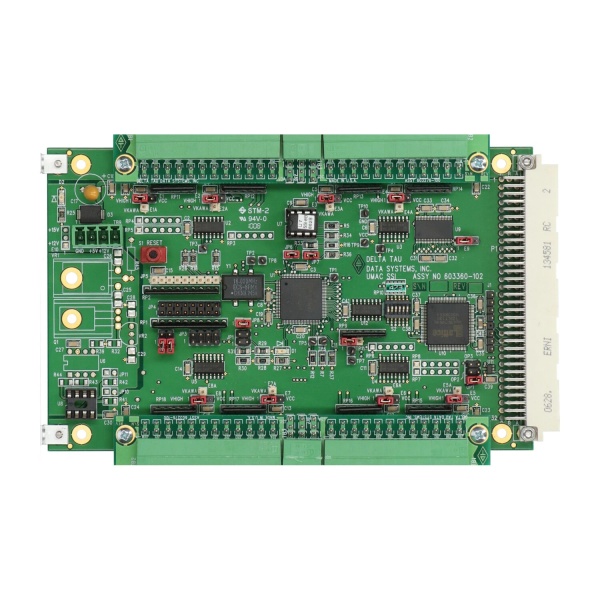

Description

ACC-53E

- •

Model Number: ACC-53E - •

Manufacturer: DELTA TAU - •

Product Type: Turbo PMAC2 Accessory Board - •

Number of Axes: 8 independent servo channels - •

Interface Type: SERCOS (SErial Real-time Communication System) - •

Communication Medium: Fiber optic ring network - •

Data Resolution: 16-bit for command and feedback data - •

Cycle Time: Configurable from 62.5 μs to 4 ms - •

Network Topology: Ring topology with redundant fiber paths - •

Maximum Network Length: 100 meters between nodes - •

Number of Nodes: Supports up to 8 drives per interface - •

Communication Protocol: SERCOS I/II compliant - •

Data Types: Position, velocity, torque commands and feedback - •

Servo Update Rate: Synchronized to SERCOS cycle time - •

Communication Interface: Parallel bus to Turbo PMAC2 CPU - •

Power Supply: +5V DC from host controller - •

Operating Temperature: 0°C to 60°C - •

Connector Type: ST-type fiber optic connectors - •

Isolation: Complete galvanic isolation via fiber optics - •

Compatibility: SERCOS-compliant drives and I/O modules ACC-53E