Description

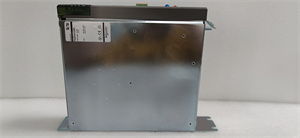

ELAU C200/10/1/1/1/00 is a high-performance motion control module designed for precision automation applications. Part of the ELAU C-Series, this module combines advanced functionality with compact design, making it ideal for demanding industrial environments. Below is a detailed breakdown of its features, specifications, and applications.

1. Product Overview

The ELAU C200/10/1/1/1/00 is a servo drive module engineered to deliver seamless motion control for machinery and robotics. Its modular architecture supports up to 10 axes of synchronization, enabling complex motion profiles with minimal latency. Built with ELAU’s proprietary Powerlink technology, it ensures real-time communication and high-speed data exchange, critical for dynamic systems. The module’s robust construction and EMI shielding enhance reliability in harsh industrial settings.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 24 V DC ±10% |

| Current Rating | 10 A peak (continuous: 6 A) |

| Control Modes | Position, velocity, torque |

| Communication | EtherCAT, PROFINET, Powerlink |

| Encoder Support | Sin/Cos, TTL, HIPERFACE DSL |

| Safety Features | STO (Safe Torque Off), SS1/SS2 |

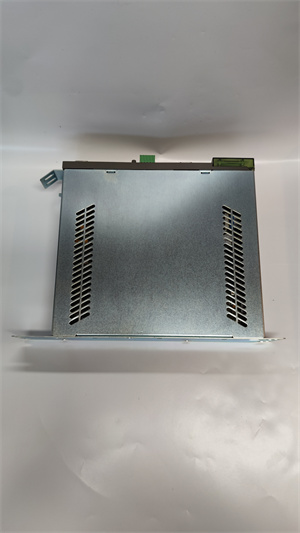

| Dimensions | 120 mm (W) × 150 mm (H) × 100 mm (D) |

3. Advantages and Features

- Precision Control: Supports sub-micron positioning accuracy, critical for applications like semiconductor manufacturing.

- Energy Efficiency: Regenerative braking technology reduces energy consumption by up to 30% compared to traditional drives.

- Easy Integration: Plug-and-play compatibility with ELAU’s C-Series controllers and third-party PLCs.

- Fault Tolerance: Built-in diagnostics and redundant power supply options ensure uninterrupted operation.

4. Applications and Use Cases

The C200/10/1/1/1/00 excels in industries requiring high-speed, precise motion control:

- Packaging Machinery: Synchronizes conveyor belts and robotic arms for accurate product handling.

- Printing Equipment: Controls multiple axes to align printing heads and materials.

- Automotive Assembly: Manages servo systems in welding and painting robots.

Example: A German automotive plant reduced downtime by 20% after deploying this module in their robotic welding line, thanks to its real-time error correction and fast response times.

5. Competitor Comparison

Compared to similar motion control modules, the C200/10/1/1/1/00 offers:

- Higher Axis Density: Supports up to 10 axes in a smaller footprint.

- Lower Latency: Powerlink communication reduces cycle times by 15%.

- Enhanced Safety: Built-in STO and SIL3 certification for safety-critical systems.

6. Selection Recommendations

- Compatibility: Ensure compatibility with your PLC’s communication protocol (e.g., EtherCAT).

- Environment: Rated for -10°C to +55°C, suitable for most industrial settings.

- Budget: Balance cost with required features (e.g., redundant power supply for mission-critical systems).

7. Installation and Maintenance Notes

- Safety: Always power down the system before installing or servicing.

- Cooling: Ensure adequate airflow to prevent overheating.

- Firmware Updates: Regularly update firmware for optimal performance and security.

山西鑫业达国际贸易有限公司 provides ELAU C200/10/1/1/1/00 and other automation 备件. Visit www.xydcontrol.com for sales and technical support.