Description

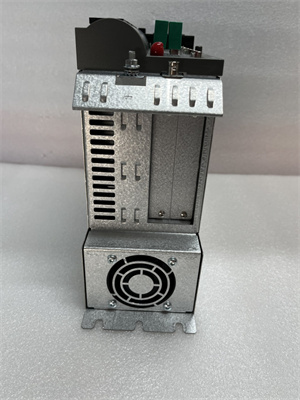

ELAU C400/A8/1/1/1/10 is a compact, high-performance motion controller designed for industrial automation systems. As part of ELAU’s PACDrive series, this controller integrates advanced motion control, real-time processing, and flexible communication capabilities to optimize performance in applications requiring precision and scalability. Below is a detailed breakdown of its features, specifications, and applications.

1. Product Overview

The ELAU C400/A8/1/1/1/10 is a PACDrive C400 A8 controller engineered for real-time motion synchronization and machine automation. With support for up to 99 servo drives via SERCOS interface, it enables seamless coordination of complex systems. Its VxWorks real-time operating system ensures deterministic performance, while compatibility with Ethernet TCP/IP, PROFIBUS DP, and CANopen simplifies integration with broader automation networks. The controller features digital and analog I/O, touch probe inputs, and compact flash storage for data logging.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| CPU | ST-PC Vega |

| Memory | 128 MB RAM |

| Operating System | VxWorks RTOS |

| Communication | SERCOS, Ethernet TCP/IP, PROFIBUS DP, CANopen |

| I/O Interfaces | Digital I/O, analog I/O, RS-232/RS-485 |

| Max. Servo Drives | 99 (via SERCOS) |

| Dimensions | 163 mm × 38 mm × 58 mm |

| Weight | 0.4 kg |

3. Advantages and Features

- High-Speed Synchronization: Supports SERCOS III for real-time communication with servo drives, reducing latency.

- Flexible Programming: Compatible with IEC 61131-3 languages for PLC and motion control, enabling easy customization.

- Compact Design: Space-saving form factor ideal for machinery with limited cabinet space.

- Reliability: Over 25,000 installed systems globally, backed by a 1-year warranty.

4. Applications and Use Cases

The C400/A8/1/1/1/10 is widely used in industries requiring precise motion control:

- Packaging Machinery: Coordinates robotic arms and conveyors for high-speed packaging lines.

- Automotive Assembly: Manages multi-axis systems in welding and assembly processes.

- Textile Manufacturing: Controls looms and cutting machines with sub-millimeter accuracy.

Example: A German automotive plant reduced cycle times by 15% using this controller in their robotic welding cells, thanks to its real-time synchronization capabilities.

5. Competitor Comparison

Compared to similar controllers, the C400/A8/1/1/1/10 offers:

- Higher Drive Capacity: Supports up to 99 servo drives, surpassing many mid-range solutions.

- Enhanced Compatibility: Built-in support for multiple fieldbus protocols, eliminating the need for additional gateways.

- Efficient Data Management: Compact flash storage allows on-board recipe management and diagnostics.

6. Selection Recommendations

- Drive Requirements: Ensure compatibility with your servo drive count and communication protocols.

- Space Constraints: Opt for this model if cabinet space is limited due to its compact design.

- Future Scalability: Choose this controller for projects requiring expansion, as it supports up to 99 drives.

7. Installation and Maintenance Notes

- Safety: Power down the system before installing or servicing the controller.

- Cooling: Ensure proper ventilation to maintain optimal operating temperatures (-10°C to +55°C).

- Firmware Updates: Regularly update firmware to access new features and security patches.

山西鑫业达国际贸易有限公司 provides ELAU C400/A8/1/1/1/10 and other automation 备件. Visit www.xydcontrol.com for sales and technical support.