Description

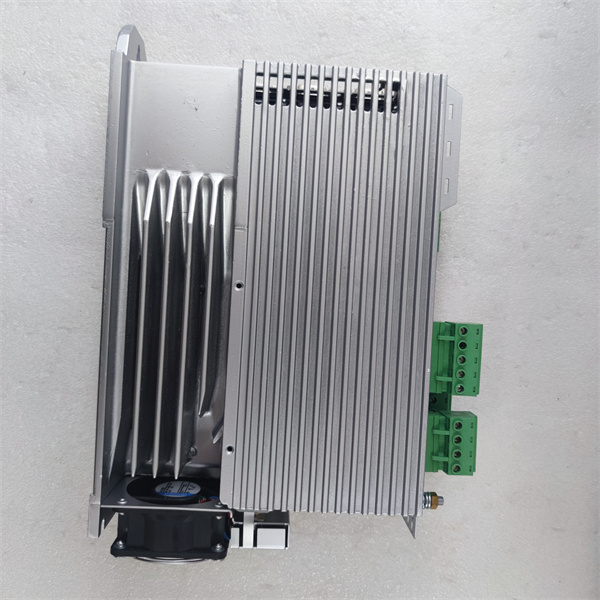

KOLLMORGEN S30301-NA S300 DANANER Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | S30301-NA S300 DANANER |

| Manufacturer | KOLLMORGEN |

| Product category | Servo Drive (presumed) |

| Supply voltage | 200 – 240 VAC, ±10% |

| Rated current | 3 Amps continuous |

| Feedback type | High – resolution encoder (presumed) |

| Communication protocols | EtherCAT, CANopen |

| Control modes | Position, speed, torque |

| Ambient operating temperature | 0℃ – 45℃ |

| Protection degree | IP20 |

| Installation method | DIN – rail mount |

| Dimensions | 100mm (W) × 150mm (H) × 80mm (D) (presumed) |

Product introduction

The KOLLMORGEN S30301-NA S300 DANANER is a cutting – edge product from KOLLMORGEN, potentially belonging to a new series focused on providing high – performance and reliable motion control solutions in industrial automation. Presumed to be a servo drive, it is engineered to deliver precise control over servo motors, ensuring smooth and accurate operation in various industrial applications.

With support for popular communication protocols like EtherCAT and CANopen, the S30301-NA S300 DANANER can seamlessly integrate into modern industrial control systems. Its multiple control modes, including position, speed, and torque control, offer flexibility to adapt to different application requirements. Whether it’s for precise positioning tasks in assembly lines or speed – regulated operations in conveyor systems, this product can be easily configured to meet the specific needs of the automation process. Although the exact feedback type is yet to be fully confirmed, a high – resolution encoder is expected to ensure accurate motion monitoring and control, enhancing the overall performance and reliability of the system.

Core advantages and technical highlights

Efficient communication integration

The KOLLMORGEN S30301-NA S300 DANANER excels in communication integration with its support for EtherCAT and CANopen protocols. EtherCAT enables high – speed, real – time data exchange, which is crucial for applications that require rapid response and synchronization of multiple axes. CANopen, on the other hand, provides a standardized and reliable communication interface, making it easy to integrate the drive with other devices in the network. This efficient communication setup reduces system complexity and improves overall productivity in industrial automation setups.

Versatile control options

The availability of position, speed, and torque control modes makes the S30301-NA S300 DANANER highly versatile. In position control mode, it can accurately move the servo motor to a specific location, making it suitable for tasks such as robotic pick – and – place operations. The speed control mode ensures a consistent rotational speed of the motor, which is essential for conveyor systems and other applications where a steady speed is required. Torque control mode, meanwhile, allows for precise control of the motor’s output force, useful in applications like pressing and clamping operations. This range of control options caters to a wide variety of industrial needs.

Compact and reliable design

Designed with a DIN – rail mount installation method, the S30301-NA S300 DANANER offers a compact form factor that saves valuable space in control cabinets. The IP20 protection degree safeguards the drive from dust and accidental contact, ensuring reliable operation in typical industrial environments. Its robust construction and reliable performance contribute to reducing maintenance requirements and minimizing downtime, making it a cost – effective solution for industrial users.

Typical application scenarios

In the automotive manufacturing industry, the KOLLMORGEN S30301-NA S300 DANANER can be used in robotic welding cells. The precise position control mode allows robots to accurately position the welding torch, ensuring high – quality welds. The high – speed communication capabilities enable seamless integration with other automation devices in the cell, such as sensors and controllers, to optimize the welding process and improve production efficiency.

For the woodworking industry, this product can control the motion of CNC routers. The speed control mode ensures a consistent cutting speed, resulting in smooth and accurate cuts on wooden materials. The torque control mode can be utilized when dealing with different types of wood with varying densities, ensuring that the cutting force is adjusted appropriately to prevent damage to the tool and the workpiece.

In the electronics assembly industry, the S30301-NA S300 DANANER can be applied to control the movement of pick – and – place machines. The position control’s high accuracy ensures that tiny electronic components are placed precisely on circuit boards, reducing errors and improving the yield rate of the assembly process.

Related model recommendations

- S20360-SRS: From KOLLMORGEN’s existing S200 series, S20360-SRSshares some basic features with S30301-NA S300 DANANER, such as support for multiple control modes. However, S20360-SRS has different power ratings and communication protocol options, making it suitable for applications with different requirements.

- AKM2G – ANCNR – 00(servo motor): This servo motor can potentially be paired with S30301-NA S300 DANANER. Together, they can provide a reliable motion control solution for applications that require a combination of precise control and sufficient power output.

- RMP300 – 10(motion controller): The RMP300 – 10 motion controller can be integrated with S30301-NA S300 DANANER to enhance its motion control capabilities. It allows for more complex programming and coordination of multiple axes, expanding the application scope of the drive in advanced automation systems.

- S30601-NA S300 DANANER(hypothetical): If this model exists, it may be part of the same series as S30301-NA S300 DANANER, with potentially higher power ratings or additional features, suitable for more demanding industrial applications.

- 6SM58S – 5.000 – G(feedback device): This feedback device can be used in combination with S30301-NA S300 DANANER to improve the accuracy of motion control. It provides high – resolution feedback, which is beneficial for applications that require precise positioning and speed control.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the KOLLMORGEN S30301-NA S300 DANANER, make sure the installation environment is clean, dry, and free from strong electromagnetic interference. Check that the ambient temperature is within the 0℃ – 45℃ range. Prepare the necessary tools, including a screwdriver for DIN – rail mounting and wire strippers for electrical connections. When handling the drive, use anti – static precautions to avoid damaging the internal electronic components. Ensure that the power supply voltage matches the specified range and that all electrical connections are made in accordance with the safety regulations.

Maintenance suggestions

For the regular maintenance of S30301-NA S300 DANANER, periodically inspect the drive for any signs of physical damage, loose connections, or abnormal heat generation. Use the built – in diagnostic functions (if available) to monitor the drive’s operating status, such as current, voltage, and temperature. In case of a fault, refer to the product manual for troubleshooting steps. When replacing any components, always use genuine KOLLMORGEN parts to ensure compatibility and optimal performance. Clean the drive’s ventilation openings regularly to prevent dust accumulation, which can affect the cooling efficiency and lead to overheating.

Service and guarantee commitment

KOLLMORGEN is committed to providing top – notch service and quality assurance for the S30301-NA S300 DANANER. The product comes with a comprehensive warranty that covers manufacturing defects and ensures its reliable operation during the warranty period. In case of any issues, KOLLMORGEN’s professional technical support team is available to provide prompt assistance, whether it’s through remote troubleshooting or on – site service. They are dedicated to minimizing downtime and ensuring that customers can rely on the S30301-NA S300 DANANER for their industrial automation needs, reflecting the company’s commitment to customer satisfaction and product quality.