Description

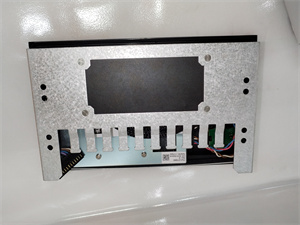

Product Specification: KONGSBERG WCC600 Watch Call Panel

The KONGSBERG WCC600 is a marine-grade watch call panel designed for unmanned engine room operations, integrating alarm monitoring, duty transfer management, and intuitive user interaction. As part of KONGSBERG’s K-Chief 600 automation system, the WCC600 ensures seamless communication between crew, control systems, and critical machinery in maritime environments.

1. Product Description

The KONGSBERG WCC600 serves as a central interface for engine room alarm management, duty engineer notifications, and system status monitoring. Key features include:

- 5.7” LCD Touchscreen: Intuitive navigation for alarm acknowledgment, system status checks, and parameter adjustments.

- CAN Bus Communication: High-speed connectivity with K-Chief 600 main computers for real-time data exchange.

- Dual Power Redundancy: 18–32V DC input ensures continuous operation during power fluctuations.

- IP44 Protection: Dust and splash resistance for reliable performance in challenging marine conditions.

- Alarm Grouping: Configurable alarm categories (up to 13 groups) for prioritized response.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Display | 5.7” TFT LCD (640×480 pixels) |

| Input Voltage | 18–32V DC |

| Power Consumption | ≤5W |

| Communication | CAN Bus (ISO 11898-2) |

| Operating Temperature | -15°C to +70°C |

| Storage Temperature | -25°C to +70°C |

| Dimensions | 240mm × 150mm × 50mm |

| Weight | 1.3kg |

| Certifications | IACS E10, IEC 60945, marine type approval |

3. Advantages and Features

- High Reliability: EMI shielding and redundant CAN network ensure stable operation in noisy environments.

- User-Friendly Design: Touchscreen interface with alarm summary, date/time display, and self-diagnostic tools.

- Flexible Integration: Supports up to 8 duty engineers and optional fire alarm integration.

- Case Study: A container ship reduced alarm response time by 20% using WCC600 for automated duty transfer alerts.

4. Application Areas and Cases

- Marine: Unmanned engine rooms, bridge control stations, and crew quarters.

- Industrial: Process monitoring in hazardous environments requiring marine-grade robustness.

- Case Study: A tanker fleet standardized WCC600 across vessels, achieving a 15% reduction in false alarm incidents.

5. Competitor Comparison

The WCC600 outperforms alternatives with:

- Extended Temperature Range: Operates in -15°C to +70°C vs. standard -10°C to +55°C.

- Larger Display: 5.7” screen compared to most 4.3”–5” panels.

- Redundant CAN Network: Built-in redundancy for mission-critical systems.

6. Selection Recommendations

- Environment: Opt for IP44-rated enclosures for outdoor or splash-prone areas.

- Redundancy: Pair with dual K-Chief 600 computers for DP-class vessels.

- Cost-Effectiveness: Ideal for mid-sized vessels requiring compliance with IMO regulations.

7. Precautions

-

Installation: Ensure proper grounding and cable routing to avoid signal interference.

-

Software Updates: Regularly update firmware to access new features and security patches.

-

Calibration: Perform touchscreen calibration annually for optimal responsiveness.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner for [KONGSBERG WCC600] and other marine automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.