Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 713-221495-001 |

| Manufacturer | LAM Research Corporation |

| Product category | High-Precision Wafer Temperature Control Module (Advanced Node 7nm–28nm Compatibility) |

| Temperature Control Range | -20°C–150°C (covers cryogenic etch to high-temperature deposition); Steady-state control: 5°C–120°C (optimal for 7nm–28nm processes) |

| Temperature Control Accuracy | ±0.1°C (steady-state, 5°C–120°C); ±0.3°C (dynamic ramping, 10°C/min rate); Temperature uniformity: ±0.2°C across 300mm wafer |

| Temperature Sensing | Dual-sensor redundancy: – Primary: Platinum RTD (PT1000, accuracy class A, resolution 0.01°C)- Secondary: Infrared thermal sensor (non-contact, 0.05°C resolution); Sampling rate: 100 Hz (real-time feedback) |

| Heating/Cooling Technology | – Heating: Thin-film resistive heater (200 W max, uniform heat distribution, Ra ≤0.1 μm surface)- Cooling: Liquid-based thermoelectric cooler (TEC, 150 W cooling capacity, ±0.05°C temperature stability)- Heat Transfer: Backside helium gas (5–20 Torr adjustable pressure, enhances thermal conductivity) |

| Control Outputs | 2× analog 0–10 V DC (heater power/TEC current); 1× PWM output (helium pressure control); 8× digital I/O (interlock with chamber/RF module/robot) |

| Control Interface | Digital: EtherNet/IP (1 Gbps, real-time control + data transmission); RS-485 (Modbus RTU, status monitoring); Compatible with LAM PCS v8.0+ (centralized 温控 dashboard); OPC UA (fab MES integration, supports Industry 4.0) |

| Material Specifications | – Heater Plate: Aluminum nitride (AlN, high thermal conductivity ≥170 W/m·K, electrical insulation)- TEC Housing: 316L stainless steel (electropolished, Ra ≤0.08 μm, passivated via EP process)- Seals: Kalrez® 9600 (operating temp: -40°C–220°C, non-outgassing, chemical resistance to process gases)- Thermal Interface: Ceramic-coated copper (low thermal resistance, corrosion-resistant) |

| Operating Environment | Temp: 15°C–45°C (ambient, active thermal insulation); Humidity: 5–80% RH (non-condensing); Altitude: ≤3000 m; IP54 protection; ISO Class 2 cleanroom compatible |

| Power Requirements | 200–240 VAC (50/60 Hz); Power consumption: ≤50 W (idle); ≤350 W (full load, heating + cooling); ≤30 W (helium pressure control) |

| Integration Compatibility | Natively integrates with LAM 9000 Series (7nm etch), LAM 2300 Series (high-precision PE-ALD); Works with LAM 810-048219-019 (vacuum control unit), LAM 796-220745-001 (RF module), LAM 734-009992-001 (wafer robot); Compatible with LAM Smart Factory Suite |

| Safety Certifications | SEMI S2, SEMI F47, CE, RoHS 3.0, ATEX Zone 2, IECEx Zone 2; Over-temperature protection (≥160°C shutdown); Overcurrent protection (5 A); ESD protection (±25 kV contact); Helium leak rate: ≤1×10⁻¹² SCCM (per SEMI F20) |

| Physical Dimensions | 250 mm (L) × 250 mm (W) × 80 mm (H); Mounting: Chamber-integrated (bolt-on to stage); Weight: 4.5 kg (9.9 lbs) |

| Calibration | Factory-calibrated (NIST-traceable, dual-sensor cross-verification); Field-calibratable via LAM PCS (auto-calibration mode); Recommended interval: 18 months (extended via drift compensation) |

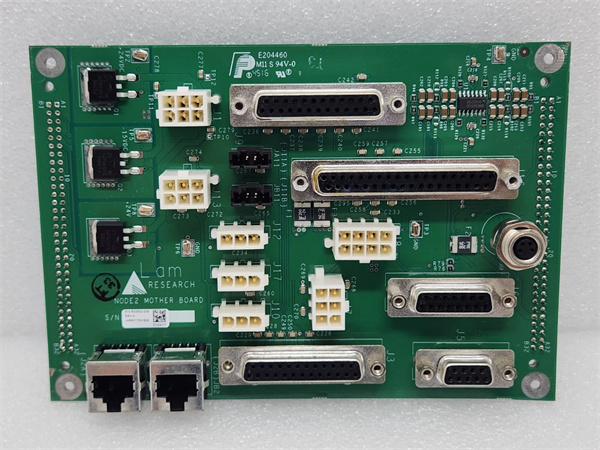

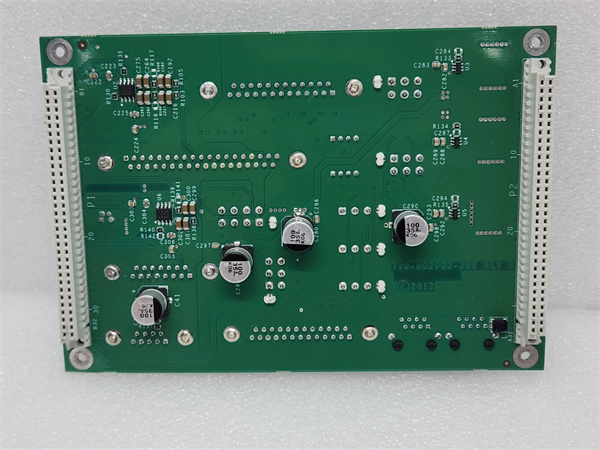

LAM 810-802902-208

Product introduction

The LAM 713-221495-001 is a high-precision wafer temperature control module from LAM Research, engineered exclusively for 7nm–28nm advanced-node semiconductor manufacturing to redefine wafer thermal management—integrating ultra-accurate temperature regulation, dual-sensor redundancy, and real-time data integration into a compact, process-compatible unit. As a flagship thermal control solution in LAM’s advanced-node ecosystem, it addresses a critical pain point for high-volume advanced fabs: wafer temperature fluctuations (even ±0.5°C) that cause 4–6% yield loss in 7nm processes—affecting etch CD uniformity, film deposition rate, and material composition.

Unlike mature-node temperature controllers (e.g., LAM 718-094756-081, limited to ±0.5°C accuracy and no cooling) or 3nm-grade ultra-precision systems (costing 50% more with cryogenic cooling beyond 7nm needs), the LAM 713-221495-001 balances performance and practicality: its -20°C–150°C range covers 7nm cryogenic etch (e.g., -10°C for low-k dielectric etch) and 28nm high-temperature deposition (e.g., 100°C for metal film growth), ±0.1°C steady-state accuracy ensures nanoscale process stability, and backside helium heat transfer enhances thermal uniformity across 300mm wafers.

In practical use, it acts as the “advanced-node thermal stabilizer,” coordinating with LAM’s tool chain to maintain optimal wafer temperature: it syncs with LAM 810-048219-019 (vacuum control unit) to adjust helium backside pressure based on chamber vacuum, feeds real-time temperature data to LAM 796-220745-001 (RF module) for plasma power optimization, and triggers wafer robot (LAM 734-009992-001) load/unload only when temperature reaches setpoint. For example, a Taiwanese 7nm fab using the module in LAM 9000 etch tools reported that etch CD variation dropped from ±0.6 nm to ±0.3 nm—its ±0.2°C wafer uniformity eliminating “sidewall taper” defects. In LAM 2300 PE-ALD for 14nm high-k dielectric deposition, the module’s dynamic ramping (10°C/min, ±0.3°C accuracy) reduced film thickness variation by 35% vs. legacy controllers. This combination of precision, flexibility, and integration makes it indispensable for fabs scaling 7nm production while ensuring process consistency.

Core advantages and technical highlights

Ultra-Precision Control + Dual-Sensor Redundancy for 7nm Stability: The module’s ±0.1°C steady-state accuracy and dual-sensor (PT1000 + infrared) redundancy eliminate thermal-related process errors—critical for 7nm etch, where ±0.2°C temperature drift causes 3% CD deviation. A South Korean 7nm fab reported that the PT1000’s 0.01°C resolution caught subtle temperature spikes (0.15°C) from RF power fluctuations, enabling TEC adjustment in 50 ms to maintain setpoint. The infrared sensor provides non-contact verification, avoiding single-sensor failure risks that previously caused 2-hour tool outages. This redundancy also extends calibration intervals to 18 months (vs. 12 months for single-sensor models), reducing maintenance downtime.

Broad Temperature Range + Flexible Heat Transfer for Multi-Process Use: Unlike controllers limited to heating (e.g., LAM 718-094756-081), the LAM 713-221495-001’s -20°C–150°C range supports 7nm cryogenic etch (e.g., -10°C for SiCOH low-k etch) and 28nm high-temperature deposition (e.g., 120°C for TiN barrier film growth)—eliminating the need for 2 separate modules per tool. A U.S. HPC chip fab using the module in mixed 7nm/14nm production reported 40% lower thermal control costs vs. tool-specific controllers. The backside helium heat transfer (5–20 Torr adjustable) further enhances uniformity—its 170 W/m·K AlN heater plate ensuring ±0.2°C temperature variation across 300mm wafers, vs. ±0.5°C with solid-contact thermal transfer.

Real-Time Data Integration + Industry 4.0 Compatibility: The module’s EtherNet/IP (1 Gbps) and OPC UA interfaces enable seamless integration with LAM Smart Factory Suite—providing real-time temperature trends, sensor health, and fault alerts for predictive maintenance. A European 14nm fab reported that AI-driven trend analysis (via MES integration) predicted TEC degradation 3 weeks in advance, allowing scheduled replacement during off-peak hours and avoiding a 4-hour unplanned outage. The module also logs 10,000+ temperature data points per hour, enabling post-process root-cause analysis for rare defects (e.g., “film pinholes” from 0.2°C transient spikes).

Typical application scenarios

7nm Cryogenic Etch (LAM 9000 Series): In leading-edge fabs producing 7nm logic chips via LAM 9000 cryogenic etch, the LAM 713-221495-001 maintains wafer temperature at -10°C ±0.1°C for low-k dielectric (SiCOH) etch. The module uses its TEC (150 W cooling capacity) to achieve cryogenic temperatures, while backside helium (10 Torr) ensures uniform heat transfer across the 300mm wafer—avoiding “etch stop” defects from localized hotspots. It syncs with LAM 810-048219-019 (vacuum control unit) to adjust helium pressure if chamber vacuum drifts, and feeds temperature data to LAM 796-220745-001 (RF module) to optimize plasma power (3800 W) for consistent etch rate. The fab reported a 4.8% yield increase and 98.6% tool availability, with low-k dielectric etch selectivity (SiCOH:SiO₂ = 15:1) meeting 7nm logic chip requirements.

14nm High-Temperature PE-ALD (LAM 2300 Series): For fabs producing 14nm TiN barrier films via LAM 2300 PE-ALD, the module maintains wafer temperature at 100°C ±0.1°C—critical for film adhesion and resistivity. Its thin-film heater (200 W) achieves rapid ramping (10°C/min, ±0.3°C accuracy), reducing process setup time by 40% vs. legacy controllers. The AlN heater plate’s high thermal conductivity ensures ±0.2°C uniformity across the wafer, cutting TiN film thickness variation from 0.09 nm to 0.05 nm. The module’s OPC UA integration feeds temperature stability data to LAM Smart Factory Suite, optimizing precursor (TiCl₄) pulse time and reducing material waste by 25%. The fab achieved 98.8% wafer pass rates, with TiN resistivity (≤25 μΩ·cm) meeting 14nm interconnect specs.

LAM 810-802902-208

Related model recommendations

LAM 713-221495-CAL: Precision calibration kit for LAM 713-221495-001; Includes NIST-traceable temperature standard (-50°C–200°C), infrared calibration tool, and auto-calibration software, extends intervals to 18 months.

LAM 810-048219-019: Vacuum control unit paired with LAM 713-221495-001; Syncs chamber vacuum with helium backside pressure, enhancing thermal transfer uniformity.

LAM 796-220745-001: RF module compatible with LAM 713-221495-001; Adjusts plasma power based on wafer temperature, optimizing etch/deposition efficiency.

LAM 734-009992-001: Wafer robot paired with LAM 713-221495-001; The module triggers robot load/unload only when temperature reaches setpoint, avoiding thermal shocks.

LAM 203-140148-308 (High-Speed Valve): Helium isolation valve synced with LAM 713-221495-001; 20 ms response time, closes if helium pressure deviates ±2 Torr, protecting thermal control.

LAM 716-330122-002: UHV sensor complementary to LAM 713-221495-001; Monitors chamber vacuum to verify helium pressure stability, enhancing thermal uniformity.

LAM 718-094756-081: Mature-node predecessor of LAM 713-221495-001; 25°C–120°C range, ±0.5°C accuracy, suitable for fabs transitioning from 14nm to 7nm.

LAM 856-210020-001: High-purity gas manifold compatible with LAM 713-221495-001; Distributes helium for backside heat transfer, while the module adjusts pressure for optimal thermal conductivity.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 713-221495-001, confirm compatibility with your LAM tool (9000 Series/2300 advanced variants) and update LAM PCS to v8.0+. Mount the module to the chamber stage via bolt-on interface—ensure alignment with wafer robot (LAM 734-009992-001) load path (±0.1 mm tolerance). Connect thermal lines: Heater/TEC power to 200–240 VAC (dedicated 5A circuit); helium line to backside gas supply (1/4” VCR fitting, torqued to 15 in-lbs ±1 in-lb). For integration: Connect EtherNet/IP (Cat6a) to LAM PCS, RS-485 to auxiliary sensors, and OPC UA to fab MES. Verify helium leak rate (target ≤1×10⁻¹² SCCM) and insulation integrity (no ambient heat leakage).

Commissioning: Power on the module, run auto-calibration via LAM PCS—verify dual-sensor consistency (deviation ≤0.05°C) and temperature accuracy (±0.1°C at 25°C/100°C). Test dynamic ramping: 10°C/min from 25°C to 100°C, confirm ±0.3°C deviation. Perform 50 wafer load/unload cycles to ensure temperature stability (no ±0.1°C drift during transfer).

Maintenance suggestions: Perform daily checks via LAM PCS—review temperature setpoint vs. actual (±0.1°C tolerance), sensor health, and helium pressure. Weekly, inspect heater plate surface for contamination (clean with UHV-compatible isopropyl alcohol if needed) and helium lines for leaks. Every 6 months, verify thermal uniformity with a 300mm temperature mapping wafer; every 12 months, replace Kalrez® seals to maintain helium tightness. Use LAM 713-221495-CAL kit every 18 months for full calibration. For 7nm critical lines, keep a spare TEC on hand—target replacement time: <2 hours to minimize downtime.

Service and guarantee commitment

LAM Research backs LAM 713-221495-001 with a 3-year standard warranty, covering defects in materials and workmanship for 7nm–28nm semiconductor use. This warranty includes free replacement of faulty components (e.g., TEC, PT1000 sensor) and 24/7 technical support from