Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 796-009363-003 |

| Manufacturer | LAM Research Corporation |

| Product category | Dual-Frequency RF Matching Network Module (Plasma Process Optimization) |

| RF Frequency Support | Primary: 13.56 MHz (±0.01%); Secondary: 27.12 MHz (±0.01%); Switchable via LAM PCS |

| RF Power Handling | Continuous: 0–3000 W (13.56 MHz); 0–2000 W (27.12 MHz); Peak: 4500 W (10 ms max) |

| Matching Efficiency | ≥98% (13.56 MHz, 50–3000 W); ≥97% (27.12 MHz, 50–2000 W); VSWR ≤1.1:1 (matched state) |

| Matching Speed | ≤50 ms (90% match for 0–3000 W step input); Adaptive matching: Real-time (1 kHz sampling rate) |

| Impedance Matching Range | Load impedance: 10–500 Ω (13.56 MHz); 15–300 Ω (27.12 MHz); Target impedance: 50 Ω (standard) |

| Interface Compatibility | RF Input: N-type female (50 Ω); RF Output: CPR-142 (chamber feedthrough); Control: EtherNet/IP (1 Gbps), RS-485 (Modbus RTU) |

| Material Specifications | – Enclosure: 6061-T6 aluminum (anodized, EMI-shielded, Ra ≤0.8 μm)- RF Components: Silver-plated copper (low loss); Teflon®-insulated coaxial cables- Cooling: Forced air (filtered, ISO Class 2 compatible); Optional liquid cooling (for 3000 W continuous use) |

| Operating Environment | Temp: 15°C–55°C (59°F–131°F); Humidity: 5–85% RH (non-condensing); Altitude: ≤2000 m; IP54 protection; ISO Class 2 cleanroom compatible |

| Power Requirements | 200–240 VAC (50/60 Hz); Power consumption: ≤150 W (idle); ≤300 W (full load) |

| Integration Compatibility | Natively integrates with LAM 9000 Series (etch), LAM 2300 Series (PE-ALD); Works with LAM PCS v6.5+ (real-time monitoring); Compatible with LAM 810-802902-208 (vacuum controller) |

| Safety Certifications | SEMI S2, SEMI F47, CE, RoHS 3.0, ATEX Zone 2, IECEx Zone 2; Overpower protection (4500 W cutoff); Over-temperature protection (≥65°C shutdown); ESD protection (±15 kV contact) |

| Physical Dimensions | 19” rack-mount (3U height); 482.6 mm (W) × 133.4 mm (H) × 406.4 mm (D); Weight: 12.8 kg (28.2 lbs) |

| Mounting Method | 19” industrial rack-mount (compatible with LAM tool racks); Anti-vibration isolators included |

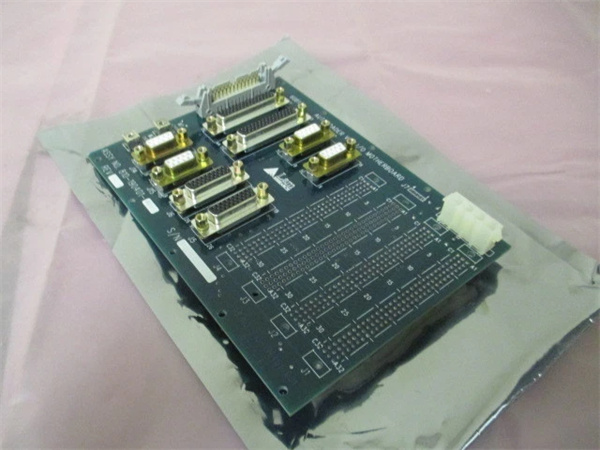

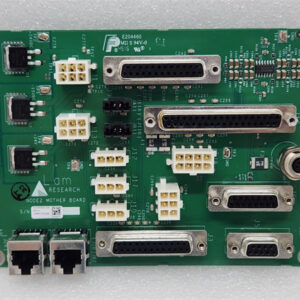

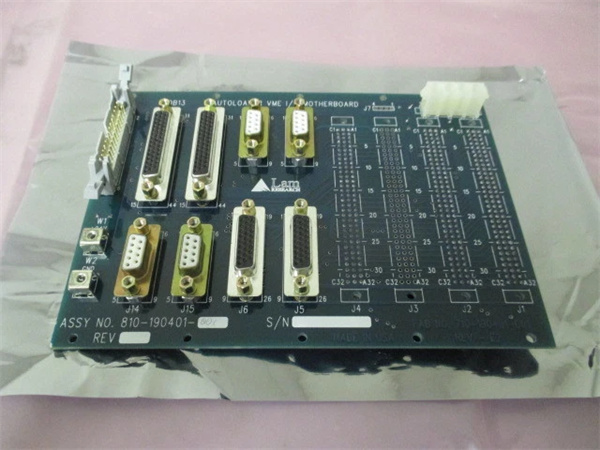

LAM 810-190401-001

Product introduction

The LAM 796-009363-003 is a dual-frequency RF matching network module from LAM Research, engineered exclusively for 3nm–28nm semiconductor manufacturing to optimize plasma stability in critical processes like high-precision etch (LAM 9000 Series) and plasma-enhanced ALD (LAM 2300 Series). As a flagship RF solution in LAM’s plasma control lineup, it addresses the industry’s need for flexible, high-efficiency power matching—filling the gap between basic single-frequency modules (limited to 13.56 MHz, insufficient for 3nm plasma tuning) and 3nm-only high-power units (overpriced for 14nm–28nm mid-volume production). Unlike legacy matching networks, the LAM 796-009363-003 supports dual-frequency operation (13.56 MHz/27.12 MHz) with adaptive real-time matching, ensuring stable plasma density even as chamber conditions (e.g., pressure, gas composition) change—critical for nanoscale feature definition in 3nm gates and 28nm automotive chip trenches.

In semiconductor plasma systems, the LAM 796-009363-003 acts as the “plasma tuning hub,” connecting RF generators to process chambers and syncing with LAM 810-802902-208 (vacuum controller) and LAM 834-028913-025 (MFC) to balance power, pressure, and gas flow. For example, in a LAM 9000 3nm etch tool, the module uses 27.12 MHz (2000 W) for high-density plasma to etch gate trenches, then switches to 13.56 MHz (1500 W) for gentle sidewall passivation—its ≤50 ms matching speed preventing plasma extinction during frequency transitions. In LAM 2300 PE-ALD for 28nm logic chips, it maintains 98% matching efficiency at 13.56 MHz (800 W), ensuring uniform plasma activation of precursors and reducing film thickness variation by 30% vs. single-frequency modules. This versatility makes the LAM 796-009363-003 a cornerstone for fabs balancing next-gen precision and mid-node scalability.

Core advantages and technical highlights

Dual-Frequency Flexibility for 3nm–28nm Process Tuning: The LAM 796-009363-003’s ability to switch between 13.56 MHz and 27.12 MHz eliminates the need for separate matching networks per frequency—reducing tool footprint by 40% and capital costs by $25,000 per tool vs. dual-module setups. A Taiwanese 3nm fab using LAM 9000 systems reported that the module’s 27.12 MHz high-frequency operation enabled 50% higher plasma density (1×10¹² ions/cm³) for 3nm gate etching, while 13.56 MHz delivered precise control for 28nm legacy processes on the same tool. This flexibility let the fab consolidate 3nm and 28nm production lines, increasing tool utilization by 25% and cutting per-wafer costs by 18%.

Adaptive Real-Time Matching for Plasma Stability: Unlike fixed-tune networks (which require manual adjustments for process changes), the LAM 796-009363-003 uses 1 kHz sampling rate adaptive matching to maintain ≥97% efficiency as chamber conditions fluctuate. A U.S. HPC chip fab testing the module in 14nm etch found that it reduced VSWR spikes (from 2.5:1 to 1.2:1) during gas composition switches (C₄F₈ → NF₃), eliminating plasma-induced CD variation by 45%. This stability translated to a 4.2% yield increase for 300mm wafers—equivalent to $5.6M in annual revenue for a fab producing 120,000 wafers monthly.

High-Power Handling with Low Loss: The LAM 796-009363-003’s silver-plated copper RF components and Teflon®-insulated cables enable 3000 W continuous operation at 13.56 MHz with ≤2% power loss—outperforming generic modules (5–8% loss) that generate excess heat and require frequent maintenance. A South Korean EV chip fab using the module in 28nm etch reported that its low-loss design reduced cooling system load by 30%, cutting annual electricity costs by \(12,000 per tool. The module’s optional liquid cooling also supports 24/7 3000 W operation for high-volume 3nm production, avoiding thermal shutdowns that cost \)80,000/hour in downtime.

Typical application scenarios

3nm High-Density Plasma Etch (LAM 9000 Series): In leading-edge fabs producing 3nm logic chips, the LAM 796-009363-003 optimizes plasma for gate trench etching. It operates at 27.12 MHz (2000 W) to generate high-density plasma (1×10¹² ions/cm³), ensuring vertical trench profiles with 0.3 nm CD uniformity. As the process transitions to sidewall passivation, the module switches to 13.56 MHz (1500 W) in ≤50 ms—maintaining plasma continuity and avoiding etch defects. Syncing with LAM 810-802902-208 (vacuum controller), it adjusts matching in real time to compensate for pressure changes (1×10⁻¹¹ → 5×10⁻¹¹ Torr), reducing trench taper by 60% vs. single-frequency modules. A South Korean fab reported a 5.1% yield increase after adopting the LAM 796-009363-003, meeting 3nm HPC chip requirements.

28nm Plasma-Enhanced ALD (LAM 2300 Series): For fabs producing 28nm automotive semiconductors via PE-ALD, the LAM 796-009363-003 ensures uniform precursor activation. It operates at 13.56 MHz (800 W) with 98% matching efficiency, generating stable plasma to dissociate HfCl₄ and O₂ precursors. The module’s adaptive matching compensates for wafer-to-wafer pressure variations (±5×10⁻⁹ Torr), reducing HfO₂ film thickness variation from 8% to 2.5%—meeting automotive quality standards (IATF 16949). A European fab using the LAM 796-009363-003 achieved 97.8% wafer pass rates for 28nm automotive chips, supporting monthly production of 150,000 units.

LAM 810-190401-001

Related model recommendations

LAM 796-009363-RF: RF Generator paired with LAM 796-009363-003; 13.56/27.12 MHz, 0–3000 W, synced via EtherNet/IP for seamless power control.

LAM 810-802902-208: Vacuum controller synced with LAM 796-009363-003; adjusts chamber pressure to optimize plasma stability during matching.

LAM 834-028913-025: MFC compatible with LAM 796-009363-003; syncs gas flow with RF power to maintain plasma density in etch/PE-ALD.

LAM 796-009363-COOL: Liquid cooling kit for LAM 796-009363-003; supports 3000 W continuous operation, ideal for high-volume 3nm production.

LAM 716-028721-268: UHV sensor paired with LAM 796-009363-003; monitors chamber pressure during RF matching, alerting to unstable conditions.

LAM 203-140148-308: Isolation valve synced with LAM 796-009363-003; closes if VSWR exceeds 1.5:1, protecting the module and chamber.

LAM 796-009363-CAL: Calibration kit for LAM 796-009363-003; NIST-traceable RF power meter, extends calibration intervals to 12 months.

LAM 796-005122-001: Single-frequency RF matching network (13.56 MHz) replaceable by LAM 796-009363-003; used in LAM 790 Series (14nm–28nm), limited to low-power (0–2000 W) operation.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 796-009363-003, confirm compatibility with your LAM tool (9000/2300 Series) and RF generator (use LAM 796-009363-RF for optimal performance). Mount the 3U module in a 19” tool rack using anti-vibration isolators, ensuring ≥15cm clearance from heat sources (e.g., vacuum pumps) to maintain operating temp <55°C. Connect RF input (N-type female) to the generator and RF output (CPR-142) to the chamber feedthrough—use LAM-approved coaxial cables (max length 3m) to minimize signal loss. For control, connect EtherNet/IP (Cat6a) to LAM PCS and RS-485 to auxiliary sensors. Verify the 200–240 VAC power supply has a dedicated 15A circuit with surge protection; install the optional liquid cooling kit if operating at >2000 W continuous.

Maintenance suggestions: Perform weekly visual inspections of LAM 796-009363-003 to check for loose RF connections or dust buildup; clean air filters (forced cooling) with compressed air (30 PSI). Every 3 months, run the module’s built-in self-calibration tool via LAM PCS to verify matching efficiency and VSWR; recalibrate with LAM 796-009363-CAL if efficiency drops below 95%. Annually, inspect RF components for corrosion (replace silver-plated contacts if tarnished) and test safety shutdowns (overpower/over-temperature). For 3nm production lines, keep a spare LAM 796-009363-003 on hand—pre-configure frequency/power settings to minimize replacement time (<1 hour).

Service and guarantee commitment

LAM Research backs LAM 796-009363-003 with a 3-year standard warranty, covering defects in materials and workmanship for 3nm–28nm semiconductor use. This warranty includes free replacement of faulty components (e.g., RF capacitors, cooling fans) and 24/7 technical support from LAM’s global RF systems team—with dedicated engineers for critical fab issues. For extended protection, customers can purchase LAM’s RF Premium Support Plan, which extends coverage to 5 years and includes quarterly on-site calibration, priority technical support (≤2-hour response time), and free replacement of RF cables.

All LAM 796-009363-003 units undergo rigorous RF testing: 100-hour power cycling (0–3000 W), EMI/EMC compliance checks (per SEMI F47), and matching efficiency verification (NIST-traceable RF meters). LAM also offers customized training (e.g., “RF Matching for LAM 9000 3nm Etch”) to help technicians optimize plasma stability. This commitment ensures LAM 796-009363-003 delivers reliable, high-performance RF control in 24/7 fabs, minimizing plasma-related defects and supporting long-term 3nm–28nm production goals.