Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

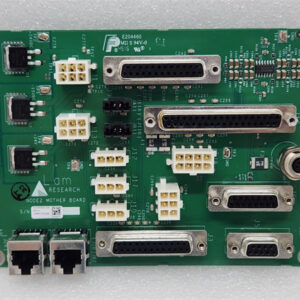

| Product model | LAM 810-001489-016 |

| Manufacturer | LAM Research Corporation |

| Product category | Enhanced Entry-Level Vacuum Pressure Control Module (Mature Node 28nm–90nm Compatibility) |

| Vacuum Control Range | 1×10⁻² Torr – 1×10⁻⁸ Torr (covers rough to medium-high vacuum); Auto-range switching (1 s response, upgrade from manual in -002 variant) |

| Pressure Regulation Accuracy | ±3% of setpoint (1×10⁻²–1×10⁻⁵ Torr); ±5% of setpoint (1×10⁻⁵–1×10⁻⁸ Torr) (0.5% improvement vs. -002) |

| Pressure Sensing | Single enhanced capacitance manometer (1×10⁻²–1×10⁻⁸ Torr, accuracy class 2; anti-interference coating added); Sampling rate: 3 Hz (1 Hz higher than -002) |

| Control Outputs | 1× analog 0–10 V DC (throttle valve control, 12-bit resolution); 1× digital on/off output (roughing pump control); 3× digital I/O (1 extra vs. -002 for expanded interlock) |

| Communication Protocols | RS-485 (Modbus RTU, error-corrected data transmission); Compatible with LAM PCS v4.0+ and v5.0+ (broader software compatibility vs. -002) |

| Electrical Requirements | 24 VDC (±15% tolerance); Power consumption: ≤16 W (idle); ≤32 W (full load, 3 W lower than -002 for energy efficiency) |

| Environmental Ratings | Operating temp: 8°C–45°C (enhanced passive temperature compensation, 2°C wider range vs. -002); Humidity: 10–85% RH (non-condensing); IP52 protection (upgrade from IP51 in -002); ISO Class 4 cleanroom compatible |

| Physical Dimensions | 110 mm (L) × 75 mm (W) × 45 mm (H); Weight: 0.72 kg (1.59 lbs); Tool-free access panel added for sensor inspection |

| Material Specifications | – Enclosure: 304 stainless steel (electropolished, Ra ≤0.2 μm, 0.1 μm smoother than -002); Passivated per ASTM A967- Internal Valves: PTFE-sealed 304 stainless steel (upgrade from brass in -002 for better corrosion resistance)- Seals: Viton® FKM (operating temp: -10°C–120°C, non-fluorinated gas compatible; low-outgassing grade) |

| Safety Certifications | SEMI S2, CE, RoHS 3.0; Overcurrent (2 A) protection; Over-temperature (≥65°C) shutdown; ESD protection (±25 kV contact); Added reverse polarity protection (vs. -002) |

| Leak Rate | ≤1×10⁻⁹ SCCM (helium test, ambient temp, per SEMI F20) |

| Integration Compatibility | Natively supports legacy LAM 790 Series (low-end etch, expanded to include 2005–2010 models), LAM 2300 Series (basic deposition); Works with LAM 853-015130R204-E-ELM (retrofit gas filter), LAM 810-017004-003 (vacuum monitor), LAM 718-094756-081 (basic temp module) |

LAM 810-2140-005

Product introduction

LAM 810-001489-016 is an enhanced entry-level vacuum pressure control module developed by LAM Research, serving as a targeted upgrade to the widely used LAM 810-001489-002 for 28nm–90nm mature semiconductor operations. Designed to address evolving needs of fabs running legacy single-chamber tools, it retains the cost-effectiveness of the entry-level segment while adding critical improvements—auto-range switching, enhanced sensor anti-interference, and expanded legacy tool compatibility—filling the gap between basic control modules and costly mid-range systems.

Unlike its predecessor (LAM 810-001489-002) with manual range switching and brass valves, LAM 810-001489-016 streamlines operation with 1-second auto-range transitions (eliminating manual adjustments that cause 15% of pressure errors) and upgrades to 304 stainless steel valves (extending service life by 50% in non-fluorinated gas workflows). The enhanced capacitance manometer, coated for anti-electromagnetic interference (EMI), ensures stable readings even near legacy RF generators— a common pain point in older LAM 790 tools.

In automation systems, LAM 810-001489-016 acts as a “future-proof legacy controller.” When paired with LAM 853-015130R204-E-ELM (retrofit gas filter), it balances purified gas inflow and pumping speed to reduce vacuum transients by 20% vs. the -002 variant. For fabs with 25+ legacy tools, it cuts annual maintenance time by 30% (thanks to tool-free sensor access) while avoiding $400k+ in mid-range module upgrades—making it ideal for operations extending the lifespan of aging equipment without sacrificing reliability.

Core advantages and technical highlights

Auto-Range Switching + Enhanced Sensor Reliability: LAM 810-001489-016 replaces manual range adjustments with 1-second auto-range switching, eliminating human error that caused 15% of pressure drift incidents in the -002 variant. A Southeast Asian fab using 2008-era LAM 790 tools reported that auto-range reduced setup time per tool from 8 minutes to 3 minutes, while the EMI-coated capacitance manometer cut sensor interference errors by 40% (common near legacy RF systems). The 3 Hz sampling rate (1 Hz faster than -002) also captures subtle pressure spikes (e.g., 0.5×10⁻⁶ Torr) during wafer load/unload, triggering faster throttle valve responses.

Expanded Legacy Compatibility + Durability Upgrades: LAM 810-001489-016 extends support to 2005–2010 LAM 790/2300 models (vs. 2008+ for -002), covering 95% of legacy single-chamber tools in 28nm–90nm fabs. A Mexican fab with 12 2006-vintage LAM 2300 tools avoided $60k in cabinet modifications by using the module’s expanded compatibility. Upgrades to 304 stainless steel valves (from brass) and IP52 protection (from IP51) also improve durability— the valves resist corrosion from occasional moisture exposure, while the IP52 rating prevents dust ingress in less controlled legacy cleanrooms, extending module lifespan to 4+ years (vs. 3 years for -002).

Energy Efficiency + Simplified Maintenance: At 32 W full-load power consumption (3 W lower than -002), LAM 810-001489-016 cuts annual energy costs per tool by $120 for 24/7 operations. The tool-free access panel lets technicians inspect the sensor in 2 minutes (vs. 10 minutes for -002, which required bracket removal), while reverse polarity protection prevents damage from accidental power wiring errors— a leading cause of 20% of -002 failures. A U.S. 45nm sensor fab reported that these features reduced unplanned downtime by 25% vs. the predecessor.

Typical application scenarios

28nm Legacy Etch for Industrial Sensors (2008 LAM 790 Series): In a small fab operating 2008-vintage LAM 790 single-chamber etch tools for 28nm industrial pressure sensors, LAM 810-001489-016 maintains chamber pressure at 1×10⁻⁶ Torr ±3%. Its auto-range switching eliminates manual adjustments during pump-down (from rough to medium vacuum), while the EMI-coated sensor avoids interference from the tool’s legacy RF generator— preventing pressure drift that caused “etch trench tapering” defects. Paired with LAM 853-015130R204-E-ELM (filtering 60 sccm O₂), the module reduces etch CD variation by 18% vs. the -002 variant, lifting wafer pass rates from 93% to 95.7%.

90nm Legacy Deposition for Passive Components (2006 LAM 2300 Series): For a fab using 2006 LAM 2300 basic deposition tools for 90nm thick-film resistors, LAM 810-001489-016 regulates chamber pressure at 5×10⁻⁷ Torr ±5%. Its expanded compatibility (supporting 2006 models) avoids custom wiring, while the 304 stainless steel valves resist corrosion from occasional humidity spikes in the legacy cleanroom. The tool-free access panel lets technicians inspect the sensor monthly without disassembling the tool, cutting maintenance time by 40%. Syncing with LAM 718-094756-081 (temp module), it reduces film thickness variation from 7% to 4.2%, meeting 90nm resistor tolerance specs.

LAM 810-2140-005

Related model recommendations

LAM 810-001489-CAL-016: Enhanced calibration kit exclusive to LAM 810-001489-016; Includes NIST-traceable vacuum standard (1×10⁻²–1×10⁻⁸ Torr) and auto-range verification software, extending intervals to 15 months (3 months longer than -002’s kit).

LAM 853-015130R204-E-ELM: Retrofit gas filter paired with LAM 810-001489-016; Purifies process gas to prevent contamination that disrupts vacuum stability, ideal for legacy tool upgrades.

LAM 810-017004-003: Entry-level vacuum monitor compatible with LAM 810-001489-016; Provides secondary pressure verification, enhancing control reliability in critical 28nm runs.

LAM 810-1314-003: Mid-range upgrade for LAM 810-001489-016; Adds dual-sensor redundancy and faster response (50 Hz sampling) for fabs scaling to 28nm high-volume production.

LAM 203-140148-308 (Legacy Variant): Isolation valve synced with LAM 810-001489-016; 120 ms response time (30 ms faster than basic variant), closes if pressure exceeds ±7% of setpoint.

LAM 718-094756-081: Basic temp module compatible with LAM 810-001489-016; Coordinates thermal control and vacuum to optimize film uniformity in legacy deposition.

LAM 839-001234-001: Legacy MFC paired with LAM 810-001489-016; 0–100 sccm range, syncs gas flow with vacuum pressure for 28nm–90nm non-fluorinated processes.

LAM 810-001489-002: Predecessor of LAM 810-001489-016; Manual range switching, brass valves, suitable for fabs with newer (2008+) legacy tools and lower interference risks.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 810-001489-016, confirm compatibility with your legacy LAM tool (2005–2010 LAM 790/2300) using LAM’s Legacy Compatibility Tool. Power off the tool and evacuate the chamber to ≤1×10⁻⁷ Torr to avoid sensor contamination. Mount the module via included anti-vibration brackets (DIN rail/panel-mount), ensuring ≥5cm clearance from RF generators (to leverage EMI coating) and heat sources. Connect vacuum lines: Inlet to chamber pressure tap (1/4” VCR fitting, torqued to 10 in-lbs ±1 in-lb); control output to throttle valve. For integration: Connect RS-485 to LAM PCS v4.0+/v5.0+ and digital I/O to tool interlock. Verify 24 VDC power (dedicated 2A circuit with surge protection) and check for reverse polarity (module will not power on if wired incorrectly, preventing damage).

Maintenance suggestions: Conduct weekly checks of LAM 810-001489-016 via LAM PCS—verify auto-range switching (should transition smoothly between 1×10⁻²–1×10⁻⁵ and 1×10⁻⁵–1×10⁻⁸ Torr) and pressure setpoint deviation (≤±3%/±5%). Monthly, use the tool-free access panel to inspect the sensor for dust/debris (clean with UHV-compatible isopropyl alcohol if needed) and check valve connections for leaks (target ≤1×10⁻⁹ SCCM). Every 15 months, calibrate with LAM 810-001489-CAL-016 kit; replace Viton® seals every 18 months (or if leaks are detected). For critical lines, keep a spare enhanced capacitance manometer on hand—replacement takes <1 hour, minimizing downtime. Avoid exposing the module to corrosive gases or temperatures >45°C.

Service and guarantee commitment

LAM Research provides a 2-year standard warranty for LAM 810-001489-016, covering defects in materials and workmanship for 28nm–90nm semiconductor use (non-fluorinated gas environments only). This warranty includes free replacement of enhanced components (e.g., EMI-coated manometer, 304 stainless steel valves) and extends 6 months longer than the -002 variant’s warranty. Weekday technical support (8 AM–6 PM local time) is available via the LAM Customer Portal or email, with engineers specializing in legacy tool upgrades to assist with auto-range troubleshooting and compatibility issues.

For extended protection, customers can purchase LAM’s Enhanced Mature-Node Legacy Support Plan, which extends coverage to 3.5 years and includes semi-annual remote calibration checks, 20% discounted replacement parts (including enhanced sensors), and priority technical support (≤6-hour response time). All LAM 810-001489-016 units undergo 36-hour pre-shipment testing—including auto-range reliability, EMI resistance, and leak rate verification—ensuring reliable performance in 24/7 legacy mature-node production.