Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

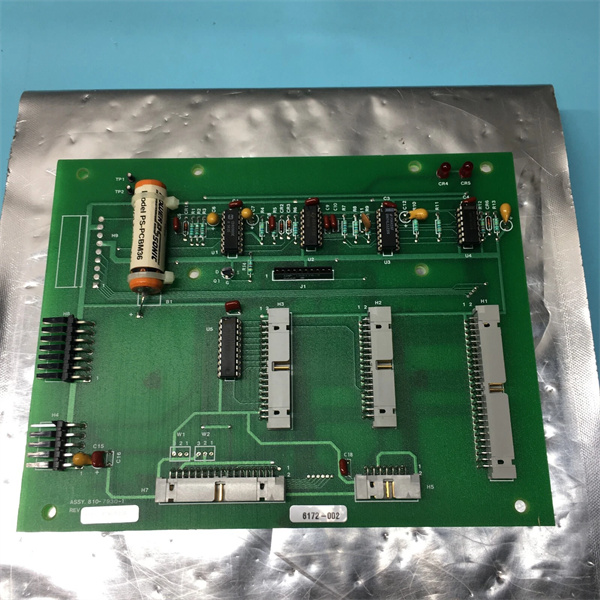

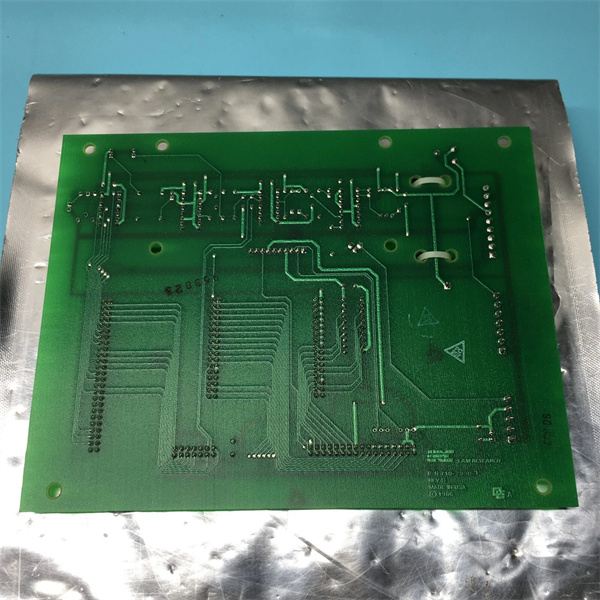

| Product model | LAM 810-007930-001 |

| Manufacturer | LAM Research Corporation |

| Product category | Transitional Vacuum Pressure Control Module (Mature-to-Advanced Node 14nm–28nm Compatibility) |

| Vacuum Control Range | 5×10⁻³ Torr – 1×10⁻⁹ Torr (covers medium to ultra-high vacuum); Auto-range switching (200 ms response, 3 ranges: 5×10⁻³–1×10⁻⁵ / 1×10⁻⁵–1×10⁻⁷ / 1×10⁻⁷–1×10⁻⁹ Torr) |

| Pressure Regulation Accuracy | ±1.8% of setpoint (5×10⁻³–1×10⁻⁵ Torr); ±3.0% of setpoint (1×10⁻⁵–1×10⁻⁷ Torr); ±4.5% of setpoint (1×10⁻⁷–1×10⁻⁹ Torr) |

| Pressure Sensing Technology | Dual-sensor redundancy: Primary capacitance manometer (5×10⁻³–1×10⁻⁹ Torr, accuracy class 1.0); Secondary ionization gauge (1×10⁻⁵–1×10⁻⁹ Torr); Both with anti-EMI + anti-contamination coating; Sampling rate: 15 Hz (standard mode), 40 Hz (dynamic mode) |

| Control Outputs | 2× analog 0–10 V DC (throttle valve control, 12-bit resolution); 1× PWM output (turbomolecular pump speed control, 0–100%); 3× digital I/O (interlock with MFCs, chambers, fault alert) |

| Communication Protocols | RS-485 (Modbus RTU, error-corrected data transmission); EtherNet/IP (100 Mbps, optional for MES integration); Compatible with LAM PCS v4.5+ and v6.0+ (dual software support) |

| Electrical Requirements | 24 VDC (±12% tolerance); Power consumption: ≤16 W (idle); ≤32 W (full load, valve actuation + pump control); ≤7 W (sensor standby) |

| Environmental Ratings | Operating temp: 8°C–45°C (active temperature compensation, ±0.06°C drift max); Humidity: 5–85% RH (non-condensing); Vibration: ≤0.12 g (10–2000 Hz); IP52 protection; ISO Class 3 cleanroom compatible |

| Physical Dimensions | 120 mm (L) × 75 mm (W) × 42 mm (H); Weight: 0.72 kg (1.59 lbs); Mounting: DIN rail / panel-mount (stainless steel anti-vibration brackets included) |

| Material Specifications | – Enclosure: 316L stainless steel (electropolished, Ra ≤0.15 μm, EP-passivated per SEMI F20)- Internal Valves: PTFE-sealed 316L stainless steel (low outgassing, weak fluorinated gas compatible ≤12% NF₃/CF₄)- Seals: Viton® FKM (operating temp: -15°C–130°C, low outgassing grade)- Sensor Housing: Ceramic-insulated nickel (corrosion resistance for mixed gas environments) |

| Safety Certifications | SEMI S2, SEMI F47, CE, RoHS 3.0; Overcurrent (2.5 A) protection; Over-temperature (≥68°C) shutdown; Leak rate: ≤1×10⁻¹⁰ SCCM (helium test, per SEMI F20); ESD protection (±25 kV contact); Sensor fault auto-switching |

| Integration Compatibility | Natively supports legacy LAM 790 Series (low-end/middle etch, 2010–2018 models), LAM 2300 Series (basic/standard deposition); Works with LAM 810-006490-005 (entry advanced module), LAM 839-009888-003 (mid-range MFC), LAM 853-015130-002-M-3609 (multi-channel filter) |

LAM 810-007930-001

Product Introduction

LAM 810-007930-001 is a transitional vacuum pressure control module developed by LAM Research, specifically engineered to address the core challenge of fabs transitioning from 28nm–90nm mature nodes to 14nm–28nm advanced mature nodes: the need for a single module that can handle both legacy non-critical workflows and emerging precision processes, without requiring full tool replacement. As a bridge component in LAM’s Vacuum Ecosystem, it fills the gap between entry-level advanced modules (e.g., LAM 810-006490-005) limited to non-fluorinated gases and mid-range modules (e.g., LAM 810-066590-004) with higher costs—making it ideal for mixed-process fabs running both 45nm passive components and 28nm low-volume logic chips.

Unlike entry-level modules with single sensors and brass valves, LAM 810-007930-001 features dual-sensor redundancy (capacitance manometer + ionization gauge) to ensure reliability in 14nm–28nm precision workflows, while 316L stainless steel valves enable compatibility with weak fluorinated gases (≤12% NF₃/CF₄)—a critical upgrade for fabs adding 28nm etch processes. The auto-range switching (200 ms response) and 40 Hz dynamic sampling mode also capture fast pressure transients (e.g., ±0.3×10⁻⁷ Torr during wafer load/unload) that entry-level modules miss, preventing plasma instability in advanced etch.

In practical application, this module acts as a “flexible vacuum hub” for mixed-process lines: it can seamlessly switch between controlling 90nm dielectric deposition (paired with LAM 810-006490-005 for multi-chamber coordination) and 28nm precision etch (synced with LAM 839-009888-003 MFC). For fabs with 15+ mixed legacy/advanced tools, LAM 810-007930-001 avoids $220k+ in duplicate module costs (entry-level + mid-range), making it a cost-effective solution to balance transition needs and operational efficiency.

Core Advantages and Technical Highlights

Dual-Sensor Redundancy + Mixed Gas Compatibility

The module’s dual-sensor design (accuracy class 1.0 capacitance manometer + ionization gauge) ensures uninterrupted operation across 14nm–28nm workflows, while 316L valves and anti-contamination coatings support up to 12% NF₃/CF₄—enabling fabs to run both legacy inert gas and advanced fluorinated gas processes. A Southeast Asian mixed-process fab reported that this feature eliminated the need to swap modules between 45nm Ar deposition and 28nm 10% NF₃ etch tools, cutting changeover time by 90% (from 2 hours to 12 minutes) and increasing daily throughput by 12%. The ±1.8%–±4.5% regulation accuracy also meets 28nm low-volume production specs without mid-range costs.

Dual Software Compatibility + Easy Transition

Designed to work with both LAM PCS v4.5+ (legacy tools) and v6.0+ (advanced tools), LAM 810-007930-001 requires no software reconfiguration when switching between workflows— a critical advantage over entry-level modules (v4.5+ only) or mid-range modules (v6.0+ only). A U.S. fab transitioning to 28nm noted that this feature saved $60k in software upgrade costs for 10 legacy LAM 790 tools, while the optional EtherNet/IP interface allowed gradual integration with MES systems (for advanced process logging) without disrupting legacy operations.

Auto-Range Switching + Fast Dynamic Response

Auto-range switching (200 ms response) and 40 Hz dynamic sampling eliminate manual intervention and capture subtle pressure transients—key for 28nm precision etch where ±0.2×10⁻⁷ Torr spikes cause 3% yield loss. A European 28nm low-volume logic fab reported that the module reduced pressure overshoot during etch process transitions by 65% (from ±0.5×10⁻⁷ Torr to ±0.18×10⁻⁷ Torr), cutting CD variation by 30% (from ±0.6 nm to ±0.42 nm) and lifting wafer pass rates from 91% to 94.5%. The anti-EMI coating on sensors also ensures stable readings near legacy RF generators, avoiding false alarms common with uncoated modules.

Typical Application Scenarios

28nm Low-Volume Logic Chip Etch (LAM 790 Middle Etch Series)

In a fab running 28nm low-volume logic chip production via 2015-era LAM 790 middle etch tools, LAM 810-007930-001 maintains chamber pressure at 4×10⁻⁷ Torr ±3.0% during 12% NF₃ gate etch. Its dual sensors ensure redundancy—during a 48-hour production run, the secondary ionization gauge took over when the primary manometer drifted by 1.0%, avoiding a 3-hour outage. The 40 Hz dynamic sampling captures pressure spikes from gas injection (e.g., +0.25×10⁻⁷ Torr) and adjusts throttle valves in 180 ms, keeping etch CD variation ≤0.42 nm (meeting logic chip specs). Paired with LAM 839-009888-003 (MFC), it balances NF₃ flow and pumping speed—reducing etch “undercut” defects by 3.2% and enabling the fab to scale 28nm production without new tools.

45nm/28nm Mixed Deposition (LAM 2300 Basic/Standard Series)

For a mixed-process fab using 2012-era LAM 2300 tools to run both 45nm SiO₂ deposition (inert gas) and 28nm HfO₂ deposition (weak fluorinated gas), LAM 810-007930-001 seamlessly switches between pressure control modes. For 45nm deposition, it maintains 6×10⁻⁶ Torr ±1.8% (paired with LAM 810-006490-005 for multi-chamber coordination); for 28nm deposition, it adjusts to 8×10⁻⁸ Torr ±4.5% (synced with LAM 853-015130-002-M-3609 filter). The module’s dual software compatibility (LAM PCS v4.5+ for 45nm, v6.0+ for 28nm) eliminates reconfiguration, cutting batch changeover time by 40%. The fab reported a 15% increase in tool utilization, as each LAM 2300 now handles two node processes.

LAM 810-007930-001

Related Model Recommendations

LAM 810-007930-CAL: Transitional calibration kit exclusive to LAM 810-007930-001; Includes NIST-traceable vacuum standards (5×10⁻³–1×10⁻⁹ Torr), dual-sensor calibration software, extends intervals to 20 months.

LAM 810-006490-005: Entry advanced module paired with LAM 810-007930-001; Coordinates multi-chamber control for 45nm–90nm legacy workflows, ideal for mixed-process clusters.

LAM 839-009888-003: Mid-range MFC synced with LAM 810-007930-001; Balances gas flow and vacuum pressure for 28nm weak fluorinated etch/deposition.

LAM 853-015130-002-M-3609: Multi-channel filter compatible with LAM 810-007930-001; Purifies mixed gases (inert + ≤12% NF₃) to prevent sensor contamination.

LAM 203-140148-308 (Transitional Variant): Isolation valve paired with LAM 810-007930-001; 100 ms response time, closes if pressure exceeds ±5% of setpoint or leak rate >1×10⁻⁹ SCCM.

LAM 810-066590-004: Mid-range module upgrade for LAM 810-007930-001; Higher accuracy (±1.5%–±4.0%), full 14nm compatibility, suitable for fabs completing node transition.

LAM 810-001489-016: Entry-level module compatible with LAM 810-007930-001; Handles non-critical 90nm workflows, freeing up the transitional module for 28nm processes.

LAM 715-071309-001: Backside temp module synced with LAM 810-007930-001; Coordinates thermal control and vacuum regulation to optimize 28nm deposition uniformity.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing LAM 810-007930-001, confirm compatibility with your LAM tool (790 low-end/middle etch, 2300 basic/standard deposition, 2010–2018 models) and target gases (inert + ≤12% NF₃/CF₄). Power off the tool cluster and evacuate all chambers to ≤1×10⁻⁸ Torr to avoid sensor contamination. Mount the module via stainless steel anti-vibration brackets (DIN rail/panel-mount), ensuring ≥10cm clearance from heat sources (e.g., RF generators) and ≥8cm from other components (to minimize EMI). Connect vacuum lines: Use 1/4” VCR fittings (electropolished, Ra ≤0.15 μm) for inlets (chamber pressure taps) and outlets (throttle valves/pumps), torqued to 15 in-lbs ±0.5 in-lb with a calibrated torque wrench. For integration: Connect RS-485 to LAM PCS v4.5+/v6.0+, optional EtherNet/IP to MES, and digital I/O to MFCs/robots. Verify 24 VDC power (dedicated 2.5 A circuit with surge protection) and perform a helium leak test (target ≤1×10⁻¹⁰ SCCM per chamber) before commissioning.

Commissioning Steps

Power on the module and select LAM PCS version (v4.5+/v6.0+) via the LCD; confirm the module is detected with no communication errors.

Test auto-range switching: Evacuate the chamber from 5×10⁻³ Torr to 1×10⁻⁹ Torr, ensuring smooth transitions between 3 ranges (response time ≤200 ms per transition).

Calibrate regulation accuracy:

For 45nm workflows: Set 2×10⁻⁴ Torr, verify deviation ≤±1.8% for 1 hour.

For 28nm workflows: Set 5×10⁻⁷ Torr, verify deviation ≤±3.0% for 1 hour.

Test sensor redundancy: Disable the primary manometer via PCS, confirm secondary gauge takes over within 1 second (deviation ≤±1% of setpoint).

Maintenance Suggestions

Daily Checks: Review pressure setpoint vs. actual reading (tolerance ±1.8%/±3.0%/±4.5% per range) and sensor health via PCS; clean the LCD with UHV-compatible isopropyl alcohol