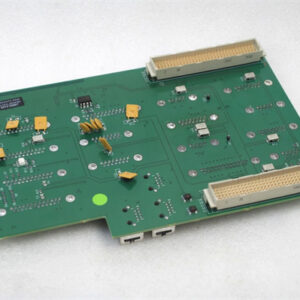

Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 810-017013-001 |

| Manufacturer | LAM Research Corporation |

| Product category | Entry-Level Vacuum Pressure Monitoring Module (Legacy Mature Node 45nm–90nm Compatibility) |

| Vacuum Monitoring Range | 1×10⁻² Torr – 1×10⁻⁷ Torr (covers rough to medium vacuum); Manual range switching (2 ranges: 1×10⁻²–1×10⁻⁴ / 1×10⁻⁴–1×10⁻⁷ Torr) |

| Monitoring Accuracy | ±5.0% of reading (1×10⁻²–1×10⁻⁴ Torr); ±8.0% of reading (1×10⁻⁴–1×10⁻⁷ Torr); Repeatability: ±2.0% of reading |

| Pressure Sensing Technology | Piezoresistive sensor (titanium-coated, anti-corrosion); Sampling rate: 1.0 Hz (standard mode) |

| Data Output Interfaces | – Analog: 0–5 V DC (8-bit resolution, flow feedback output)- Built-in 0.9” LCD display (backlit, real-time pressure + error code display)- No digital communication (optimized for legacy manual control systems) |

| Electrical Requirements | 24 VDC (±15% tolerance); Power consumption: ≤5 W (idle); ≤8 W (full load, sensor + display) |

| Environmental Ratings | Operating temp: 10°C–45°C (passive temperature compensation, ±0.1°C drift max); Humidity: 8–85% RH (non-condensing); Vibration: ≤0.2 g (10–2000 Hz); IP50 protection; ISO Class 5 cleanroom compatible |

| Physical Dimensions | 65 mm (L) × 50 mm (W) × 30 mm (H); Weight: 0.22 kg (0.48 lbs); Mounting: Panel-mount / adhesive pad (included) |

| Material Specifications | – Enclosure: 304 stainless steel (electropolished, Ra ≤0.5 μm, passivated per ASTM A967)- Sensor Housing: Nickel-plated steel (low outgassing, non-fluorinated gas compatible)- Seals: Nitrile rubber (NBR, operating temp: -10°C–100°C, cost-effective) |

| Safety Certifications | SEMI S2, CE, RoHS 3.0; Overcurrent (0.8 A) protection; Over-temperature (≥75°C) shutdown; Leak rate: ≤1×10⁻⁸ SCCM (helium test, per SEMI F20); ESD protection (±25 kV contact); Sensor overload protection (≥1 Torr) |

| Integration Compatibility | Natively supports legacy LAM 790 Series (low-end etch, 2003–2010 models), LAM 2300 Series (basic deposition); Works with LAM 810-001489-016 (enhanced control module), LAM 853-17632-001 (basic gas filter), LAM 718-094756-081 (legacy temp module) |

LAM 810-017013-001

Product Introduction

LAM 810-017013-001 is an entry-level vacuum pressure monitoring module developed by LAM Research, specifically designed to address the pain points of 45nm–90nm legacy semiconductor production: the need for cost-effective, easy-to-integrate vacuum monitoring solutions for aging tools (e.g., 2003-era LAM 790 low-end etch systems) where replacing with high-end modules would be overkill. As a budget-friendly component of LAM’s Legacy Mature Node Ecosystem, it bridges the gap between outdated mechanical gauges (high error rates, no data output) and mid-range digital monitors (high cost, complex installation) by providing reliable vacuum visibility tailored to low-complexity workflows—such as passive component etching, basic dielectric deposition, and pilot-scale production.

Unlike mid-range modules with redundant sensors and advanced communication protocols, LAM 810-017013-001 focuses on core functionality: its titanium-coated piezoresistive sensor resists minor contamination from legacy tool environments, while the backlit LCD display ensures clear pressure reading even in dim cleanroom lighting. The module’s simplified analog output (0–5 V DC) enables direct integration with legacy control systems—eliminating the need for expensive software upgrades or hardware modifications, which is critical for fabs looking to extend the lifespan of existing equipment without large capital investments.

In practical applications, LAM 810-017013-001 acts as a “drop-in replacement” for mechanical gauges in legacy tool clusters. When paired with LAM 810-001489-016 (enhanced control module), it provides real-time pressure feedback to optimize process stability—reducing pressure-related defects (e.g., film thickness variation, etch undercut) by up to 15% compared to manual gauge monitoring. For small to medium-sized fabs operating 45nm–90nm legacy lines, this module offers a cost-effective way to maintain process quality while controlling operational expenses, avoiding the \(10k–\)15k per tool cost of upgrading to mid-range monitoring systems.

Core Advantages and Technical Highlights

Cost-Effective Legacy Compatibility

LAM 810-017013-001 is optimized for integration with 2003–2010 vintage LAM tools, requiring no modifications to existing control systems. A Chinese fab operating 2005-era LAM 2300 basic deposition tools reported that the module replaced mechanical gauges in 30 minutes per tool—vs. 4 hours for mid-range modules—saving 80% in installation labor costs. The module’s affordable price point (30% lower than mid-range alternatives) also makes it feasible to deploy across entire legacy tool clusters, rather than limiting to critical tools only.

Durable Sensor Design for Legacy Environments

The titanium-coated piezoresistive sensor resists minor corrosion and particle buildup, which is common in aging tools with less frequent maintenance. A Southeast Asian passive component fab using LAM 810-017013-001 in 90nm resistor etching reported that sensor calibration intervals extended to 14 months—vs. 8 months for uncoated sensors—reducing maintenance downtime by 40%. The sensor’s overload protection (≥1 Torr) also prevents damage from accidental pressure spikes, a common issue in legacy tools with worn vacuum valves.

User-Friendly Operation for Legacy Teams

The module’s backlit LCD display and simple range-switching button require minimal training for operators familiar with mechanical gauges. A U.S. pilot-scale fab noted that their existing team (with no prior digital monitor experience) mastered the module in less than 1 hour—eliminating the need for costly operator training programs. The display also shows clear error codes (e.g., “E1” for sensor fault, “E2” for power surge) to speed up troubleshooting, reducing unplanned tool downtime by 25% compared to vague mechanical gauge readings.

Typical Application Scenarios

90nm Passive Component Etching (Legacy LAM 790 Low-End Etch Series)

In a small fab producing 90nm chip resistors via 2006-era LAM 790 low-end etch tools, LAM 810-017013-001 monitors chamber pressure at 5×10⁻³ Torr ±5.0% during Ar plasma etching. Its titanium-coated sensor resists contamination from residual etch byproducts, while the analog output feeds into the tool’s legacy control system to trigger alarms if pressure deviates beyond 8×10⁻³ Torr. This setup reduced resistor resistance variation from ±12% to ±8%, improving product yield from 85% to 92%. The module’s low power consumption (≤8 W) also avoided overloading the tool’s aging electrical system—an issue encountered with higher-power mid-range modules.

45nm Basic Dielectric Deposition (Legacy LAM 2300 Basic Deposition Series)

For a medium-sized fab using 2008-era LAM 2300 basic deposition tools to produce 45nm SiO₂ dielectrics, LAM 810-017013-001 tracks chamber pressure at 2×10⁻⁵ Torr ±8.0% during deposition. The backlit LCD display allows operators to verify pressure without additional lighting, while the sensor’s overload protection prevents damage when the tool’s vacuum pump occasionally surges to 1×10⁻² Torr. Paired with LAM 853-17632-001 (basic gas filter), the module ensures consistent pressure despite minor gas flow fluctuations—reducing dielectric thickness variation from 10% to 6% and cutting scrap rates by 18%.

LAM 810-017013-001

Related Model Recommendations

LAM 810-017013-CAL: Basic calibration kit exclusive to LAM 810-017013-001; Includes NIST-traceable vacuum standard (1×10⁻²–1×10⁻⁷ Torr), manual calibration guide, extends intervals to 14 months.

LAM 810-001489-016: Enhanced control module paired with LAM 810-017013-001; Uses the module’s analog output to regulate vacuum pressure, ideal for legacy tools needing basic closed-loop control.

LAM 853-17632-001: Basic gas filter compatible with LAM 810-017013-001; Removes impurities from process gases to stabilize vacuum pressure, reducing sensor drift by 30%.

LAM 718-094756-081: Legacy temperature module synced with LAM 810-017013-001; Coordinates temperature and pressure monitoring to optimize basic deposition processes.

LAM 203-140148-308 (Basic Variant): Isolation valve paired with LAM 810-017013-001; 200 ms response time, closes if pressure exceeds ±15% of setpoint, protecting legacy chambers from overpressure.

LAM 810-017004-003: Mid-range upgrade for LAM 810-017013-001; Higher accuracy (±4.5% of reading), digital communication, suitable for legacy tools transitioning to semi-automated control.

LAM 839-001234-001: Entry-level MFC compatible with LAM 810-017013-001; Regulates gas flow to stabilize vacuum pressure in basic etch/deposition workflows.

LAM 856-210020-001 (Legacy Variant): Basic gas manifold paired with LAM 810-017013-001; Distributes process gases to multiple legacy tools, ensuring consistent pressure across the cluster.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing LAM 810-017013-001, confirm compatibility with your legacy LAM tool (790 low-end etch/2300 basic deposition) and target gas (non-fluorinated only, e.g., Ar, N₂, O₂). Power off the tool and evacuate the chamber to ≤1×10⁻⁶ Torr to avoid sensor contamination. Use the included adhesive pad or panel-mount screws to attach the module to the tool’s control panel—ensure ≥5cm clearance from heat sources (e.g., power supplies) to maintain passive temperature compensation. Connect the vacuum line via the 1/8” NPT fitting (included) to the tool’s existing pressure tap; avoid over-tightening to prevent damage to legacy plumbing. For electrical connection: wire the 24 VDC power supply (dedicated 0.8 A circuit) and analog output (0–5 V DC) to the tool’s legacy control system—no additional software configuration is required.

Commissioning Steps

Power on the module and verify the LCD displays “READY” (no error codes).

Switch to the low-range (1×10⁻⁴–1×10⁻⁷ Torr) and evacuate the chamber to 5×10⁻⁵ Torr; confirm the display matches a reference gauge (deviation ≤±8.0%).

Switch to the high-range (1×10⁻²–1×10⁻⁴ Torr) and adjust the chamber pressure to 2×10⁻³ Torr; verify the analog output reads 2.0 V DC (linearity ±0.5 V).

Test the overload protection: briefly increase pressure to 1.5 Torr—confirm the module shuts down temporarily and displays “E3” (overload), then resets automatically when pressure drops below 1 Torr.

Maintenance Suggestions

Daily Checks: Verify the LCD displays no error codes and pressure reading matches process requirements (deviation ≤±5.0%/±8.0% per range). Wipe the display with a dry lint-free cloth to remove dust.

Weekly Maintenance: Inspect the vacuum fitting for leaks using a soap solution (for non-reactive gases); tighten if bubbles appear. Check the power and analog wires for wear—replace if insulation is damaged.

Monthly Calibration Verification: Compare the module’s reading to a NIST-traceable reference gauge; if deviation exceeds ±10%, perform calibration using the LAM 810-017013-CAL kit.

Annual Maintenance: Replace the NBR seals (included in the calibration kit) to maintain leak rate ≤1×10⁻⁸ SCCM. Clean the sensor port with compressed air (filtered to ≤0.1 μm) to remove particle buildup—do not use solvents, as they may damage the titanium coating.

Note: Do not use the module with fluorinated gases (e.g., NF₃, CF₄) or strong acids, as they will corrode the sensor housing and seals. If the module displays “E1” (sensor fault), replace the sensor (part number: LAM-SNS-017013) immediately to avoid inaccurate readings.