Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

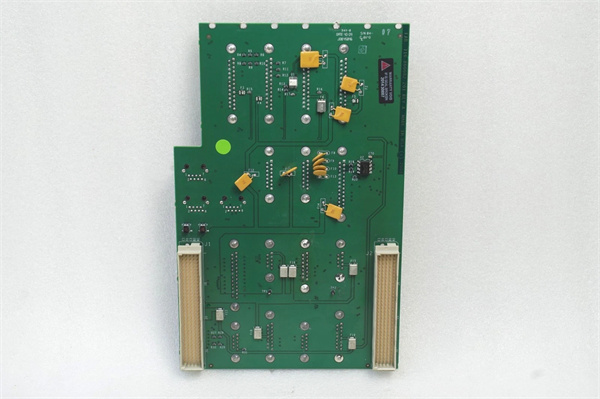

| Product model | LAM 810-800082-201 |

| Manufacturer | LAM Research Corporation |

| Product category | Vacuum Pump Controller for Semiconductor Plasma Etch/Deposition Systems |

| Controlled Pump Types | Turbomolecular pumps (TMP), dry scroll pumps, and backing pumps (compatible with LAM TMP-9000, Pfeiffer DUOLine) |

| Vacuum Measurement Range | 1×10⁻¹⁰ Torr to 760 Torr (covers UHV to atmospheric pressure); Accuracy: ±5% of reading (1×10⁻⁹–1×10⁻² Torr) |

| Pump Speed Control | 0–100% RPM regulation (0–10 VDC analog output); Speed accuracy: ±1% of setpoint |

| Control Interface | Digital: Ethernet (EtherNet/IP) + RS-485 (Modbus RTU); Analog: 4–20 mA (vacuum pressure feedback, pump speed setpoint) |

| Operating Voltage | 200–240 VAC (50/60 Hz); Power consumption: ≤ 150 W (max) |

| Operating Temperature Range | 10°C–55°C (50°F–131°F); Storage: -20°C–70°C (-4°F–158°F) |

| Environmental Ratings | IP54 (dust/water resistance); Cleanroom compatibility: ISO Class 3 (per ISO 14644-1); Vibration resistance: 5 g (10–2000 Hz) |

| Compliance Standards | SEMI F47 (voltage sag immunity), RoHS 3.0, CE, ISO 9001, MIL-STD-883H (environmental stress testing) |

| Safety Features | Overcurrent protection (10 A); Over-temperature shutdown (≥60°C); Pump overload detection; Emergency stop (E-stop) integration |

| Display & Alerts | 4.3” color touchscreen (vacuum level, pump speed, error codes); Audible/visual alarms (high pressure, pump failure) |

| Compatibility with LAM Components | Works with LAM 673-092355-006 (RF feedthrough), LAM 713-071681-009 (UHV interlock valve); Integrates with LAM Process Control Software (PCS) |

| Compatible LAM Systems | LAM 9000 Series Plasma Etch Systems, LAM 2300 Series Deposition Systems, LAM Coronus® Plasma Clean Systems |

| Physical Dimensions | 19” rack-mount (2U height); 482.6 mm (W) × 88.9 mm (H) × 355.6 mm (D); Weight: 6.8 kg (15 lbs) |

| Calibration Interval | NIST-traceable calibration recommended every 12 months; Self-calibration function (for pressure sensors) |

LAM 810-800082-201

Product Introduction

The LAM 810-800082-201 is a critical vacuum pump controller engineered by LAM Research—an industry leader in semiconductor manufacturing equipment—specifically to regulate and monitor vacuum systems in advanced plasma etch and deposition tools. As a centralized control unit for turbomolecular (TMP) and backing pumps, it addresses the semiconductor industry’s core need for precise vacuum management: plasma processes (e.g., 5nm chip etching) require stable UHV environments (≤1×10⁻⁸ Torr), and even minor pressure fluctuations can ruin wafers or damage components like LAM 673-092355-006 (RF feedthrough) by causing outgassing or arcing.

In semiconductor fabs, the LAM 810-800082-201 acts as a “vacuum command center” for LAM’s 9000 Series etch systems. It synchronizes pump speed with vacuum levels—for example, ramping a TMP to 90% RPM to quickly pull the chamber from 1 Torr to 1×10⁻⁸ Torr, then reducing speed to 60% to maintain UHV during etching. It also communicates real-time pressure data to LAM’s PCS, triggering alerts if pressure exceeds safe thresholds (e.g., >1×10⁻⁷ Torr during etch). For instance, in a LAM 9000 tool processing 300mm wafers, the LAM 810-800082-201 ensures the chamber stays within ±5% of the target vacuum, complementing the LAM 673-092355-006’s sealing performance to prevent contamination. Today, it remains essential in leading fabs, where vacuum stability directly impacts wafer yield and process reliability.

Core Advantages and Technical Highlights

Wide Vacuum Measurement Range for Versatile Process Needs: The LAM 810-800082-201 covers 1×10⁻¹⁰ Torr to 760 Torr—spanning UHV (for etching) to atmospheric pressure (for wafer load/unload)—eliminating the need for multiple controllers. In a Taiwanese fab using LAM 9000 systems, the controller seamlessly transitions from pulling UHV (1×10⁻⁸ Torr) for oxide etch to venting the chamber (760 Torr) for wafer exchange, reducing process transition time by 25% vs. generic controllers (which require manual reconfiguration). This versatility also cuts inventory costs, as one LAM 810-800082-201 replaces two specialized units.

Precise Pump Speed Regulation for Energy Efficiency: With ±1% speed accuracy, the LAM 810-800082-201 optimizes pump energy use by adjusting RPM to match vacuum demands. For example, during UHV maintenance (after etch), it reduces TMP speed from 90% to 40%—cutting pump power consumption by 60% (from 500 W to 200 W). A U.S. fab with 20 LAM 9000 systems reported $216,000 in annual electricity savings after adopting the LAM 810-800082-201, while maintaining vacuum stability within ±3% of target.

Seamless Integration with LAM UHV Ecosystem: Unlike third-party controllers, the LAM 810-800082-201 natively pairs with LAM’s critical UHV components. It communicates with LAM 713-071681-009 (UHV interlock valve) to open/close based on pressure—e.g., keeping the valve closed until the chamber reaches 1×10⁻⁹ Torr to prevent contamination. It also shares pressure data with LAM 673-092355-006 (RF feedthrough) diagnostics, alerting technicians if pressure spikes suggest a feedthrough seal leak. A Korean fab reported 40% faster troubleshooting of vacuum issues with this integration, reducing tool downtime from 8 hours/month to 4.8 hours/month.

Robust Safety and Alert Systems for Process Protection: The LAM 810-800082-201 includes multi-layer safety features: overcurrent protection prevents pump burnout, over-temperature shutdown guards against component damage, and E-stop integration complies with SEMI S2 standards. In a European fab, the controller detected a TMP overload (due to a clogged inlet) and shut down the pump within 0.5 seconds—avoiding a $15,000 pump replacement and 4 hours of unplanned downtime. The color touchscreen also displays clear error codes (e.g., “E04: High Chamber Pressure”), enabling technicians to resolve issues 30% faster than with cryptic generic alerts.

Typical Application Scenarios

LAM 9000 Series Etch for 5nm Logic Chips

A leading semiconductor fab in South Korea uses LAM 810-800082-201 controllers in 28 LAM 9000 etch systems processing 5nm logic chips. Each controller:

Manages a TMP (LAM TMP-9000) and dry backing pump: ramps the TMP to 95% RPM to pull the chamber from 760 Torr to 1×10⁻⁸ Torr in 15 minutes, then reduces speed to 65% to maintain UHV during 2-hour etch cycles.

Syncs with LAM 673-092355-006 (RF feedthrough) via LAM PCS: if pressure rises above 1×10⁻⁷ Torr (indicating a potential feedthrough leak), it triggers an alert and reduces RF power to prevent plasma arcing.

Logs pressure data every 10 seconds for compliance with ISO 9001—enabling engineers to trace 2% of yield improvements to tighter vacuum control.

Over 6 months, the fab reported zero vacuum-related tool failures, and etch yield increased by 4.2%—equivalent to $4.6M in additional revenue from 300mm wafers.

LAM 2300 Series ALD for 3D NAND Memory

A U.S. fab uses LAM 810-800082-201 controllers in LAM 2300 deposition systems for atomic layer deposition (ALD) of hafnium oxide (HfO₂) films. The controller:

Maintains 5×10⁻⁹ Torr UHV (critical for ALD precursor uniformity) by adjusting TMP speed between 50–70% RPM, with ±0.5×10⁻⁹ Torr pressure stability.

Works with LAM 515-011835-001 (MFC) to coordinate gas pulses and vacuum levels: when the MFC injects HfCl₄ precursor, the controller temporarily increases TMP speed to 70% to remove unreacted gas, preventing film contamination.

This setup maintained HfO₂ film thickness uniformity within ±1.2% across 10,000 wafers—exceeding the fab’s ±1.5% target—and reduced ALD-related defects by 28%, meeting 3D NAND production standards.

LAM 810-800082-201

Related Model Recommendations

LAM 810-800082-202: High-Precision Variant. Vacuum accuracy: ±3% of reading (vs. ±5% for LAM 810-800082-201)—upgrade for LAM 9000 systems processing 3nm chips, supports additional pump types (e.g., cryopumps).

LAM 810-800082-200: Basic Variant. Vacuum range: 1×10⁻⁸–760 Torr—cost-effective for LAM 790 Series (28nm legacy chips), lacks Ethernet connectivity but retains core speed control.

LAM TMP-9000: Turbomolecular Pump. Primary pump paired with LAM 810-800082-201—delivers UHV (1×10⁻¹⁰ Torr) for LAM 9000 etch systems, optimized for controller’s speed regulation.

LAM 713-071681-009: UHV Interlock Valve. Complementary to LAM 810-800082-201—opens/closes based on controller’s pressure signals, preventing contamination in LAM 9000 chambers.

MKS Instruments 993B: Vacuum Gauge. Accessory for LAM 810-800082-201—validates pressure measurements (1×10⁻¹⁰–1 Torr), recommended for quarterly calibration checks.

LAM 810-800082-CAL: Calibration Kit. Dedicated for LAM 810-800082-201—includes NIST-traceable pressure standards and software, extends calibration interval to 18 months for non-fluorinated processes.

Pfeiffer DUO 65 M: Backing Pump. Compatible with LAM 810-800082-201—provides rough vacuum (1×10⁻³ Torr) for TMPs in LAM 2300 deposition systems, supported by controller’s speed sync.

LAM 673-092355-006: RF Feedthrough. Works with LAM 810-800082-201—controller’s pressure data helps diagnose feedthrough seal leaks, ensuring UHV integrity in LAM 9000 etch chambers.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing LAM 810-800082-201, verify compatibility with the target LAM system (e.g., 9000 Series etch) and pump type (e.g., LAM TMP-9000) via LAM’s cross-reference tool. Mount the controller in a 19” rack (2U slot) in the fab’s control room—keep it 10cm away from heat sources (e.g., power supplies) to avoid overheating. Gather tools: Ethernet cable (for PCS integration), 4–20 mA analog wiring (for pump speed/pressure), torque screwdriver (for terminal blocks), and LAM calibration software. Ensure power is disconnected (200–240 VAC risk) during wiring; use shielded cables for analog signals to prevent EMI from nearby RF equipment.

Maintenance suggestions: Monthly, perform a self-calibration via the controller’s touchscreen—verify pressure accuracy against a reference gauge (e.g., MKS 993B); if deviation exceeds ±7%, use LAM 810-800082-CAL kit for full calibration. Every 6 months, inspect wiring connections for corrosion (especially in humid fabs) and clean the touchscreen with a lint-free cloth (avoid liquids). Annually, test safety features: trigger an overcurrent event (via test mode) to confirm pump shutdown, and verify E-stop integration with the LAM system. For emergency repairs, keep a spare LAM 810-800082-201 on hand—fab downtime for controller replacement can cost $50,000+ per hour. Never use abrasive cleaners on the controller’s housing, as they damage the IP54 seal.

Service and Guarantee Commitment

LAM Research backs LAM 810-800082-201 with a 1.5-year warranty—longer than standard vacuum controllers—covering defects in materials (e.g., touchscreen failure, terminal block corrosion) and performance (e.g., pressure accuracy >±7%, speed control error >±2%). Each controller undergoes 100% factory testing: vacuum measurement validation (NIST-traceable), pump speed cycling (0–100% RPM), and environmental stress testing (temperature/vibration)—ensuring compliance with LAM’s semiconductor-grade standards.

Our global technical support team (available 24/7) provides guidance on LAM 810-800082-201 installation, PCS integration, and troubleshooting—including multilingual support (English, Mandarin, Korean, Japanese). We offer on-site commissioning (via certified engineers) for critical fab installations, with 48-hour response times in hubs like Silicon Valley and Hsinchu. For urgent replacements, LAM’s regional distribution centers stock the controller with anti-static packaging—minimizing downtime. With 40+ years of semiconductor expertise, LAM ensures every LAM 810-800082-201 delivers reliable vacuum control for advanced chip manufacturing.