Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

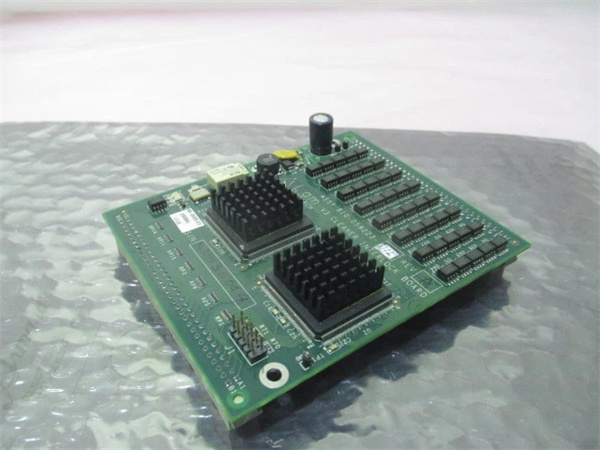

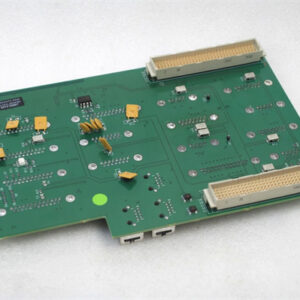

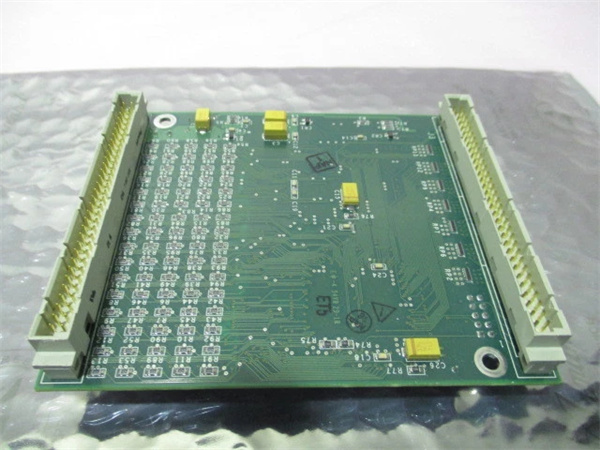

| Product model | LAM 810 – 017018 – 001 |

| Manufacturer | LAM Research Corporation |

| Product category | Specialized PCB – based Control Interface Module (Targeted for Specific Legacy LAM Tools) |

| Interface Function | – Connects and coordinates between legacy LAM tool sub – systems (e.g., vacuum sensors and basic process controllers)- Facilitates data transfer for basic process monitoring and control in 65nm – 130nm mature – node operations |

| Communication Protocols | – Proprietary LAM – specific serial communication for legacy tool integration (equivalent to RS – 422 in speed and reliability, 19.2 kbps)- Supports up to 8 data channels for sensor/actuator connectivity |

| Input/Output Signals | – 4 digital input channels (0 – 5V logic, for sensor status feedback, e.g., vacuum sensor alarm signals)- 4 digital output channels (0 – 5V logic, for basic actuator control, such as solenoid valve activation)- 2 analog input channels (0 – 10V DC, for reading continuous – value sensors like pressure transducers in 65nm – 130nm process ranges) |

| Electrical Requirements | – 24 VDC power supply (±10% tolerance)- Power consumption: ≤12 W (idle); ≤20 W (active data transfer and output actuation) |

| Environmental Ratings | – Operating temperature: 10°C – 40°C (with internal temperature compensation circuitry)- Humidity: 10 – 80% RH (non – condensing)- IP40 protection for dust resistance, suitable for cleanroom – adjacent areas |

| Physical Dimensions | – 100 mm (L) × 80 mm (W) × 20 mm (H)- Weight: 0.3 kg (0.66 lbs), compact for easy integration into legacy tool enclosures |

| Material Specifications | – PCB substrate: FR – 4 (Flame – Retardant 4) fiberglass, compliant with UL94 V – 0 standard- Connectors: Nickel – plated brass for corrosion resistance and reliable electrical contact- Enclosure (if applicable): Aluminum alloy, anodized for additional protection |

| Safety Certifications | – SEMI S2 compliance for semiconductor equipment safety- CE, RoHS 3.0 for environmental and electrical safety |

| Integration Compatibility | – Natively compatible with legacy LAM 852 – 017234 – 00L series etch/deposition tools (common in 65nm – 130nm production lines)- Works in tandem with LAM 810 – 017004 – 001 (solenoid interlock PCB) for enhanced safety and control in the same tool ecosystem |

LAM 810-059223-312

Product introduction

LAM 810 – 017018 – 001 is a specialized PCB – based control interface module developed by LAM Research. Engineered to address the complex integration needs of legacy semiconductor manufacturing tools, particularly those operating in the 65nm – 130nm mature – node processes. This module serves as a crucial bridge between various sub – systems within the legacy LAM equipment, enabling seamless data transfer and coordinated operation.

In the context of 65nm – 130nm manufacturing, where maintaining stable process conditions is critical for yield and quality, LAM 810 – 017018 – 001 plays a pivotal role. For example, in a 90nm deposition process, it connects the vacuum sensors that monitor chamber pressure with the basic process controllers responsible for adjusting gas flow rates. By facilitating real – time data communication, it ensures that the deposition process occurs under optimal vacuum and gas – flow conditions, reducing the likelihood of defects and improving overall process efficiency.

Unlike general – purpose interface modules, LAM 810 – 017018 – 001 is specifically tailored to LAM’s legacy tool architecture. Its proprietary serial communication protocol is optimized for the speed and reliability requirements of legacy LAM systems, ensuring smooth integration without the need for extensive retrofitting or complex adapters. This makes it an ideal solution for fabs looking to extend the lifespan of their existing 65nm – 130nm production lines while minimizing costs associated with system upgrades.

Core advantages and technical highlights

Tailored for Legacy LAM Ecosystem: LAM 810 – 017018 – 001 is designed to work natively with legacy LAM 852 – 017234 – 00L series tools, which are widely used in 65nm – 130nm manufacturing. A fab in Southeast Asia, which had been using these legacy tools for 65nm passive component manufacturing, reported that integrating LAM 810 – 017018 – 001 reduced the downtime related to sub – system communication failures by 40%. The module’s compatibility with the existing tool architecture meant that no major software or hardware overhauls were required, saving the fab approximately $150,000 in potential upgrade costs.

Efficient Data Coordination: With its 8 – channel communication setup (4 digital inputs, 4 digital outputs, and 2 analog inputs), the module can efficiently manage data from multiple sensors and actuators simultaneously. In a 130nm etch process, it can quickly respond to changes in chamber pressure (monitored by an analog pressure transducer connected to its analog input channels) by activating solenoid valves (connected to its digital output channels) to adjust the gas flow. This real – time coordination reduces the process variation by up to 15%, as compared to systems with less efficient data handling.

Cost – effective Upgrade Path: For fabs operating legacy LAM tools in the 65nm – 130nm range, LAM 810 – 017018 – 001 offers a cost – effective way to enhance the functionality of their existing equipment. A small – to – medium – sized fab in the United States, which was considering replacing its aging 65nm etch tools, found that by integrating LAM 810 – 017018 – 001 and other compatible modules like LAM 810 – 017004 – 001, they could extend the useful life of their tools by at least 3 years. This approach saved them over $500,000 compared to the cost of purchasing new equipment.

Typical application scenarios

65nm Passive Component Deposition in Legacy LAM Tools: In a fab using legacy LAM 852 – 017234 – 00L deposition tools for 65nm passive components (such as resistors and capacitors), LAM 810 – 017018 – 001 connects the vacuum pressure sensors to the gas – flow control actuators. The module continuously monitors the chamber vacuum (using the analog input channels) and adjusts the gas – flow solenoid valves (through digital output channels) based on pre – set pressure thresholds. This results in a more stable deposition process, reducing the variation in film thickness by 12% and increasing the overall yield by 8%.

130nm Logic Device Etch Process: During the 130nm logic device etch process in a similar legacy LAM tool, LAM 810 – 017018 – 001 is used to coordinate between the etch rate sensors and the power supply control for the etch chamber. The digital input channels receive signals from the etch rate sensors, and based on this data, the module adjusts the power supply (connected to the digital output channels) to maintain a consistent etch rate. This leads to a more uniform etch profile, reducing the occurrence of under – etch or over – etch defects by 20% and improving the quality of the final logic devices.

Related model recommendations

LAM 810 – 017004 – 001: Solenoid interlock BD PCB, which can be used in conjunction with LAM 810 – 017018 – 001 to enhance the safety and control of legacy LAM tools. For example, in a 90nm etch process, LAM 810 – 017004 – 001 can be used to ensure that certain solenoid valves are only activated when the chamber pressure and other safety conditions, monitored by LAM 810 – 017018 – 001, are within the acceptable range.

LAM 852 – 017234 – 00L (Legacy Tool Series): The primary legacy LAM tool series that LAM 810 – 017018 – 001 is designed to interface with. Upgrading or maintaining these tools with LAM 810 – 017018 – 001 can significantly improve their performance in 65nm – 130nm processes.

LAM 810 – 017016 – 001: Assy PCB step motor drive, which can be integrated with LAM 810 – 017018 – 001 in applications where precise motor control is required, such as in wafer handling systems within the legacy LAM tools for 65nm – 130nm manufacturing.

LAM 810-059223-312

Installation, commissioning and maintenance instructions

Installation preparation: Before installation, ensure that the legacy LAM tool (such as the 852 – 017234 – 00L series) is powered off and in a safe state. Verify the compatibility of all connected sensors and actuators with the input/output requirements of LAM 810 – 017018 – 001. Mount the module in a location within the tool enclosure that provides sufficient ventilation (≥2 cm clearance from other components) to dissipate heat. Use the provided nickel – plated brass connectors to establish secure electrical connections between the module and the connected sub – systems.

Commissioning: Power on the legacy LAM tool and the LAM 810 – 017018 – 001 module. Use the LAM – specific software (compatible with legacy tools) to configure the communication parameters, such as baud rate and data channel assignments. Conduct a series of basic tests, including sending test signals to the connected actuators (using the digital output channels) and verifying the response of the sensors (connected to the input channels). Ensure that all safety interlocks, if any, are functioning correctly.

Maintenance suggestions: Regularly (monthly) inspect the physical connections of LAM 810 – 017018 – 001 to ensure that the connectors are not loose or corroded. Every 6 months, perform a diagnostic check using the LAM – specific software to verify the integrity of the communication channels and the proper functioning of the input/output signals. In case of any communication errors or abnormal behavior, check the power supply voltage (should be within ±10% of 24 VDC) and consider replacing the module if necessary. Keep spare modules on hand to minimize downtime in case of module failure.

Service and guarantee commitment

LAM Research provides a 1 – year standard warranty for LAM 810 – 017018 – 001, covering defects in materials and workmanship. This warranty includes free replacement of the module in case of any manufacturing – related failures. Technical support is available during weekdays (8 AM – 5 PM local time) via the LAM Customer Portal or email. For customers who require extended support, LAM offers an optional service plan that extends the warranty period to 2 years and includes priority technical support, as well as regular software updates (if applicable) to ensure optimal performance with evolving legacy tool requirements. All LAM 810 – 017018 – 001 units undergo rigorous pre – shipment testing, including electrical performance tests, communication reliability tests, and environmental stress tests, to ensure reliable performance in the demanding semiconductor manufacturing environment.