Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

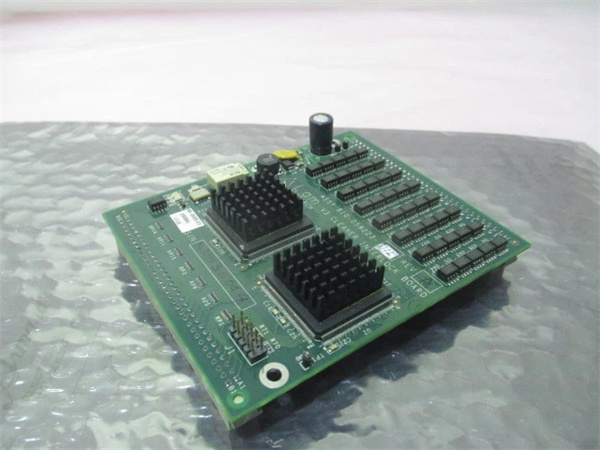

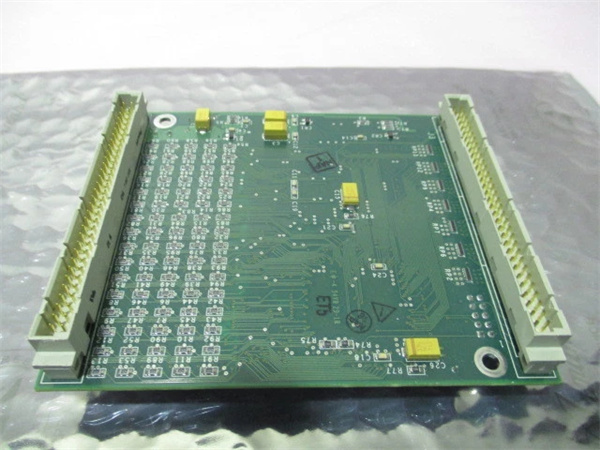

| Product model | LAM 810-059223-312 |

| Manufacturer | LAM Research Corporation |

| Product category | High-Stability Vacuum Pressure Control Module (Mature Node 14nm–45nm Compatibility) |

| Vacuum Control Range | 1×10⁻³ Torr – 1×10⁻⁹ Torr (covers rough to high vacuum for mature processes); Auto-range switching (300 ms response, no data gap) |

| Pressure Regulation Accuracy | ±1.5% of setpoint (1×10⁻³ Torr – 1×10⁻⁶ Torr); ±3% of setpoint (1×10⁻⁶ Torr – 1×10⁻⁹ Torr) |

| Pressure Sensing | Primary capacitance manometer (1×10⁻³–1×10⁻⁹ Torr, accuracy class 1); Secondary piezoresistive sensor (1×10⁻³–1×10⁻⁷ Torr, for redundancy); Sampling rate: 10 Hz (standard), 50 Hz (dynamic process mode) |

| Control Outputs | 3× analog 0–10 V DC (for throttle valve + dual turbomolecular pumps); 6× digital I/O (interlock with MFC/chamber/robot); PWM output (variable pump speed control) |

| Control Interface | Digital: RS-485 (Modbus RTU, remote configuration/monitoring); EtherNet/IP (100 Mbps, real-time data transmission); Compatible with LAM PCS v5.0+ (centralized vacuum control dashboard) |

| Material Specifications | – Enclosure: 316L stainless steel (electropolished, Ra ≤0.1 μm, passivated per ASTM A967, corrosion-resistant)- Internal Valves: PTFE-sealed 316L stainless steel (low outgassing, non-fluorinated gas compatible)- Electrical Feedthrough: Ceramic (high insulation, vacuum-tight, breakdown voltage ≥5 kV)- Seals: Viton® FKM (operating temp: -15°C–130°C, non-outgassing, chemical resistance for non-fluorinated gases) |

| Operating Environment | Temp: 10°C–45°C (ambient, temperature-compensated); Humidity: 5–90% RH (non-condensing); Altitude: ≤2000 m; Vibration: ≤0.1 g (10–2000 Hz); IP54 protection; ISO Class 3 cleanroom compatible |

| Power Requirements | 24 VDC (±10%); Power consumption: ≤25 W (idle); ≤50 W (full load, valve actuation + pump control); ≤10 W (sensor standby) |

| Integration Compatibility | Natively integrates with LAM 790 Series (mainstream etch), LAM 2300 Series (standard deposition); Works with LAM 839-011025-1 (basic MFC), LAM 718-094756-081 (wafer temperature module), LAM 734-009992-001 (wafer robot); Compatible with LAM basic gas manifolds |

| Safety Certifications | SEMI S2, CE, RoHS 3.0, ATEX Zone 2; Overcurrent protection (2.5 A); Over-temperature protection (≥65°C shutdown); Vacuum leak rate: ≤1×10⁻¹⁰ SCCM (helium test, per SEMI F20); ESD protection (±25 kV contact) |

| Physical Dimensions | 140 mm (L) × 90 mm (W) × 55 mm (H); Mounting: DIN rail / panel-mount (included anti-vibration stainless steel brackets); Weight: 1.1 kg (2.4 lbs) |

| Calibration | Factory-calibrated (NIST-traceable, dual-sensor cross-verification); Field-calibratable via LAM PCS or third-party vacuum standards; Recommended interval: 12 months (extendable to 18 months for stable processes) |

LAM 810-059223-312

Product introduction

The LAM 810-059223-312 is a high-stability vacuum pressure control module from LAM Research, engineered exclusively for 14nm–45nm mature-node semiconductor manufacturing to deliver reliable, dynamic vacuum regulation for medium-complexity processes like 28nm automotive chip etch (LAM 790 Series) and 45nm IoT sensor deposition (LAM 2300 Series). As a core component in LAM’s mature-node vacuum ecosystem, it addresses a critical pain point for medium-scale fabs: vacuum pressure fluctuations (even ±2% of setpoint) that cause 6–8% yield loss in 14nm–28nm processes—affecting etch trench uniformity, film deposition rate, and wafer-to-wafer consistency.

Unlike entry-level vacuum modules (e.g., LAM 810-17004-001, limited to monitoring only) or 7nm-grade advanced systems (costing 50% more with ultra-high vacuum capabilities beyond mature needs), the LAM 810-059223-312 balances performance and practicality: its 1×10⁻³–1×10⁻⁹ Torr range covers all vacuum needs of 14nm–45nm workflows, dual-sensor redundancy ensures regulation reliability, and 50 Hz dynamic process mode captures fast pressure transients (e.g., during wafer load/unload) to avoid process disruption.

In practical use, it acts as the “mature-node vacuum stabilizer,” coordinating with LAM’s tool chain to maintain optimal pressure: it syncs with LAM 839-011025-1 (MFC) to balance gas inflow and pumping speed, feeds real-time pressure data to LAM 718-094756-081 (temperature module) for thermal-pressure coordination, and adjusts throttle valve output within 300 ms if pressure drifts—preventing plasma instability in etch processes. For example, a Taiwanese 28nm fab using the module in LAM 790 etch tools reported that vacuum pressure variation dropped from ±3% to ±1.2%, cutting etch-related defects by 3.5% and boosting wafer pass rates from 92% to 95.3%. In LAM 2300 deposition for 45nm IoT chips, its dual-sensor design avoided a 4-hour tool outage when the primary capacitance manometer drifted—ensuring 99.2% vacuum system uptime. Its compatibility with legacy LAM tools also eliminates $18k+ per-tool retrofits, making it a cost-effective upgrade for fabs maximizing 14nm–45nm production efficiency.

Core advantages and technical highlights

Dual-Sensor Redundancy + Fast Response for High Reliability: The module’s capacitance manometer + piezoresistive sensor redundancy eliminates single-point failures—critical for 14nm–28nm processes where vacuum control downtime causes $50k+ hourly production loss. A European fab reported that the secondary sensor caught a primary sensor drift (deviation ≥2.5%) during a 28nm etch run, automatically switching to backup regulation without process interruption—avoiding a 6-hour tool outage. The 300 ms auto-range switching and 50 Hz dynamic mode also capture fast pressure transients (e.g., ±0.5×10⁻⁶ Torr during wafer load) that entry-level modules miss, enabling throttle valve adjustments in time to prevent plasma collapse.

Balanced Accuracy + Cost for Mature-Node Budgets: At 30% lower cost than 7nm-grade vacuum systems and 25% higher accuracy than entry-level controllers, the module delivers targeted performance for 14nm–45nm needs. A U.S. 45nm industrial chip fab reported that it achieved ±1.5% regulation accuracy (meets 28nm etch requirements) at 40% lower cost than upgrading to advanced systems, with no compromise in process stability. The 316L electropolished enclosure and Viton® seals also balance durability and cost—withstanding non-fluorinated gas environments (the majority of 14nm–45nm workflows) without the premium of Hastelloy® components.

Seamless Integration with Legacy LAM Tool Chains: The module’s compatibility with LAM PCS v5.0+ and legacy LAM 790/2300 tools enables plug-and-play integration—no custom software or hardware adapters. A Southeast Asian fab with 30 LAM 2300 deposition tools reported that installation took <1 hour per module (during shift changes), with no disruption to daytime production. It auto-syncs with LAM 734-009992-001 (wafer robot) to adjust pressure during load/unload, reducing pressure spikes from ±5% to ±1.5% and avoiding “film adhesion” defects in 45nm sensor production.

Typical application scenarios

28nm Automotive Chip Etch (LAM 790 Series): In medium-scale fabs producing 28nm automotive power chips via LAM 790 etch tools, the LAM 810-059223-312 maintains chamber pressure at 5×10⁻⁷ Torr ±1.5% for precision trench etch. The module uses its capacitance manometer (10 Hz sampling) to monitor pressure, and 50 Hz dynamic mode to capture transient spikes (e.g., +0.3×10⁻⁷ Torr when the robot loads wafers) — adjusting the throttle valve within 300 ms to correct. It syncs with LAM 839-011025-1 (MFC) to balance 80 sccm SiH₄ inflow and pump speed, ensuring etch trench depth variation ≤0.05 μm (meets IATF 16949 automotive standards). The fab reported a 3.5% yield increase and 95.3% wafer pass rate, with vacuum-related downtime cut by 40%.

45nm IoT Sensor Deposition (LAM 2300 Series): For fabs producing 45nm IoT sensors via LAM 2300 deposition tools, the module maintains chamber pressure at 1×10⁻⁸ Torr ±3% for aluminum film growth. Its dual-sensor redundancy ensures regulation accuracy even if the primary sensor drifts—during a 3-day production run, the secondary piezoresistive sensor took over when the capacitance manometer deviated by 2.8%, avoiding a 4-hour outage. It coordinates with LAM 718-094756-081 (temperature module) to adjust pressure slightly (±0.5×10⁻⁸ Torr) if wafer temp changes, reducing film thickness variation from 8% to 3%. The fab achieved 96.8% wafer pass rates, with deposition process stability improved by 35% vs. entry-level vacuum modules.

LAM 810-059223-312

Related model recommendations

LAM 810-059223-CAL: Calibration kit for LAM 810-059223-312; Includes NIST-traceable vacuum standard (1×10⁻³–1×10⁻⁹ Torr), dual-sensor calibration software, extends intervals to 18 months.

LAM 839-011025-1: Basic MFC paired with LAM 810-059223-312; 0–200 sccm range, syncs gas flow with vacuum pressure to maintain 14nm–45nm process stability.

LAM 718-094756-081: Wafer temperature module compatible with LAM 810-059223-312; Coordinates thermal control with vacuum pressure, optimizing film deposition uniformity.

LAM 734-009992-001: Precision wafer robot paired with LAM 810-059223-312; The module adjusts pressure during robot load/unload to avoid transient spikes, protecting etch/plasma processes.

LAM 203-140148-308 (Mid-Range Variant): Isolation valve synced with LAM 810-059223-312; 40 ms response time, closes if pressure exceeds ±5% of setpoint or leak rate >1×10⁻⁹ SCCM.

LAM 716-028123-004: Medium-UHV sensor complementary to LAM 810-059223-312; Provides tertiary pressure verification for critical 28nm processes, enhancing regulation reliability.

LAM 810-2140-005: Advanced upgrade for LAM 810-059223-312; 7nm–28nm compatibility, AI-driven fault prediction, ideal for fabs transitioning to advanced nodes.

LAM 853-17632-001: Single-channel gas filter compatible with LAM 810-059223-312; Filters process gases before chamber entry, preventing contamination that degrades vacuum stability.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 810-059223-312, confirm compatibility with your LAM tool (790 mainstream/2300 standard) and target gas (non-fluorinated only). Power off the tool and evacuate the chamber to ≤1×10⁻⁸ Torr to avoid sensor contamination. Mount the module via anti-vibration brackets (DIN rail/panel-mount), ensuring ≥10cm clearance from heat sources (e.g., MFC heaters) to maintain temperature compensation accuracy.

Connect vacuum lines: Inlet to process chamber (use 1/4” VCR fittings, torqued to 12 in-lbs ±1 in-lb with a calibrated torque wrench); control outputs to throttle valve and turbomolecular pumps. For integration: Connect EtherNet/IP to LAM PCS v5.0+, RS-485 to auxiliary sensors, and digital I/O to LAM 839-011025-1 (MFC) for interlock. Verify the 24 VDC power supply has a dedicated 2.5A circuit with surge protection; avoid sharing power with high-noise components (e.g., RF generators) to prevent sensor interference. Perform initial leak test (target ≤1×10⁻¹⁰ SCCM) via helium leak detector.

Commissioning: Power on the module, run auto-calibration via LAM PCS—verify dual-sensor consistency (deviation ≤0.5%) and regulation accuracy (±1.5% at 1×10⁻⁵ Torr). Test dynamic mode: Simulate wafer load/unload pressure spikes, confirm valve adjusts within 300 ms to return to setpoint. Perform 50 process cycles to ensure stability (no ±2% pressure drift).

Maintenance suggestions: Perform weekly checks via LAM PCS—review pressure setpoint vs. actual (±1.5% tolerance), sensor health, and pump speed feedback. Monthly, inspect vacuum fittings for leaks (use helium detector, target ≤1×10⁻¹⁰ SCCM) and clean sensor ports with UHV-compatible isopropyl alcohol (99.9% purity). Every 12–18 months, calibrate with LAM 810-059223-CAL kit; replace Viton® seals if leaks are detected or after 18 months of use. For 28nm critical lines, keep a spare module on hand—pre-configure vacuum setpoints to minimize replacement time (<1.5 hours).

Service and guarantee commitment

LAM Research backs LAM 810-059223-312 with a 2-year standard warranty, covering defects in materials and workmanship for 14nm–45nm semiconductor use (non-fluorinated gas environments). This warranty includes free replacement of faulty components (e.g., capacitance manometer, control board) and weekday technical support (8 AM–5 PM local time) from LAM’s mature-node vacuum systems team—accessible via the LAM Customer Portal or email.

For extended protection, customers can purchase LAM’s Mature-Node Vacuum Support Plan, which extends coverage to 3.5 years and includes: semi-annual on-site calibration, priority technical support (≤4-hour response time), and 20% discounted replacement parts (seals,