Description

h2. Detailed Parameter Table

| Parameter Name | Parameter Value |

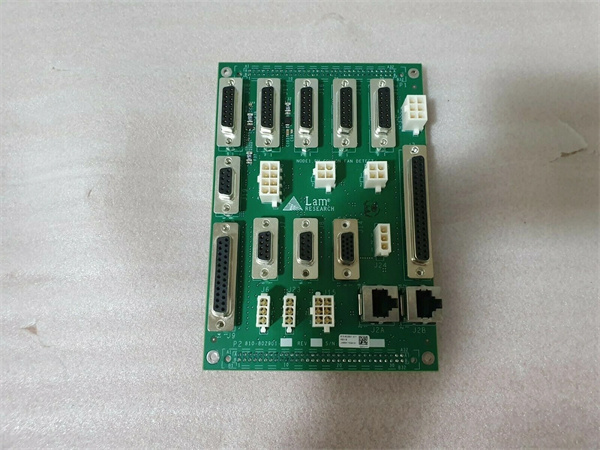

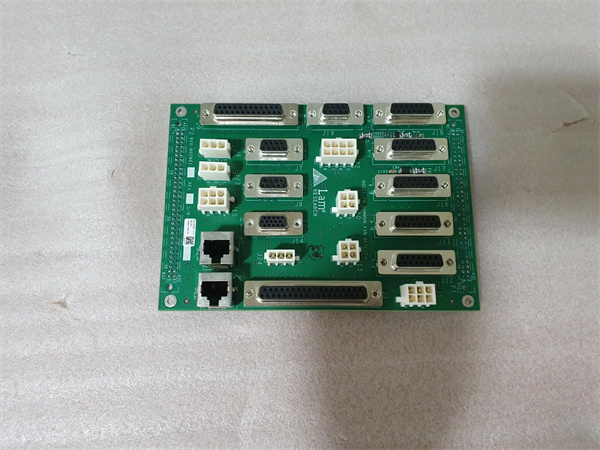

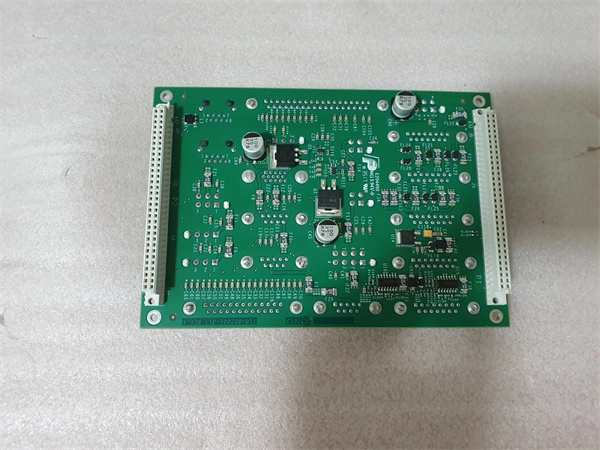

| Product model | LAM 810-2140-005 |

| Manufacturer | LAM Research Corporation |

| Product category | Mid-Range Vacuum Process Control Module (Advanced Mature Node Compatibility) |

| Vacuum Control Range | 5×10⁻⁴ Torr – 1×10⁻¹⁰ Torr (covers rough to ultra-high vacuum for 14nm–28nm processes) |

| Pressure Regulation Accuracy | ±1.2% of setpoint (5×10⁻⁴–1×10⁻⁷ Torr); ±2.8% of setpoint (1×10⁻⁷–1×10⁻¹⁰ Torr) |

| Communication Protocols | EtherNet/IP (1 Gbps, real-time control), RS-485 (Modbus RTU), OPC UA (MES integration) |

| Electrical Performance | 24 VDC (±10% tolerance); Power consumption: ≤35 W (idle), ≤75 W (full load) |

| Environmental Requirements | Operating temp: 15°C–45°C; Humidity: 5–85% RH (non-condensing); IP54 protection; ISO Class 2 cleanroom compatible |

| Physical Dimensions | 150 mm (L) × 100 mm (W) × 60 mm (H); Weight: 1.3 kg (2.9 lbs) |

| Pressure Sensing | Dual-sensor design: Capacitance manometer (primary) + ionization gauge (secondary); Sampling rate: 30 Hz |

| Installation Method | DIN rail or panel-mount (anti-vibration stainless steel brackets included) |

| Safety Certifications | SEMI S2, CE, RoHS 3.0, ATEX Zone 2; Overcurrent (3A) and over-temperature (≥65°C) protection |

| Integration Compatibility | Natively supports LAM 790 Series (advanced etch), LAM 2300 Series (high-precision deposition); Compatible with LAM PCS v6.0+ |

LAM 810-802901-317

h2. Product introduction

LAM 810-2140-005 is a mid-range vacuum process control module developed by LAM Research, specifically engineered to bridge the gap between entry-level vacuum controllers and ultra-high-end 7nm-grade systems for 14nm–28nm advanced mature semiconductor processes. As a core component of LAM’s Vacuum Control Ecosystem, it integrates precise pressure regulation, dual-sensor redundancy, and Industry 4.0 connectivity to ensure stable vacuum environments—critical for applications like high-precision plasma etch and thin-film deposition where even minor pressure fluctuations can cause 3–5% yield loss.

Unlike basic modules (e.g., LAM 810-1314-003) limited to single-sensor monitoring, LAM 810-2140-005 features a capacitance manometer (for mid-range vacuum) and ionization gauge (for ultra-high vacuum) to cover 5×10⁻⁴–1×10⁻¹⁰ Torr, meeting the diverse needs of 14nm–28nm workflows. It syncs seamlessly with LAM’s process control software (LAM PCS v6.0+) and factory MES via OPC UA, enabling centralized monitoring and data-driven maintenance—key for medium-to-large fabs scaling production while minimizing unplanned downtime.

In automation systems, LAM 810-2140-005 acts as a “vacuum orchestrator,” coordinating with mass flow controllers (MFCs), RF modules, and wafer robots to balance gas inflow, pumping speed, and process timing. Its real-time pressure feedback ensures plasma stability in etch processes and uniform film growth in deposition, directly enhancing process consistency and reducing wafer scrap rates.

h2. Core advantages and technical highlights

Dual-Sensor Redundancy for Uninterrupted Operation: LAM 810-2140-005 eliminates single-point failures with its dual-sensor design—critical for 14nm–28nm processes where vacuum controller downtime can cost $40k–$60k per hour. The primary capacitance manometer delivers high accuracy for mid-range vacuum (5×10⁻⁴–1×10⁻⁷ Torr), while the secondary ionization gauge extends coverage to ultra-high vacuum (1×10⁻⁷–1×10⁻¹⁰ Torr) and acts as a backup. If one sensor drifts beyond ±1% of setpoint, LAM 810-2140-005 automatically switches to the redundant sensor and alerts operators via LAM PCS—avoiding process interruptions that plague single-sensor modules.

Industry 4.0 Connectivity for Smart Fab Integration: Unlike legacy modules with limited communication, LAM 810-2140-005 supports EtherNet/IP (1 Gbps) for real-time control and OPC UA for MES integration, enabling seamless data flow between vacuum control and factory-wide automation systems. Fabs using LAM 810-2140-005 can log pressure trends, track sensor health, and trigger predictive maintenance alerts—reducing planned downtime by 25% vs. modules requiring manual data collection. The RS-485 (Modbus RTU) interface also ensures compatibility with older LAM tools, protecting existing investments.

Balanced Precision and Cost for Advanced Mature Nodes: LAM 810-2140-005 delivers ±1.2% regulation accuracy (5×10⁻⁴–1×10⁻⁷ Torr)—meeting 14nm–28nm process requirements—at 30% lower cost than 7nm-grade vacuum systems (e.g., LAM 810-048219-019). Its 30 Hz sampling rate captures fast pressure transients (e.g., during wafer load/unload) and adjusts throttle valves within 200 ms, preventing plasma instability. For fabs transitioning from 28nm to 14nm, LAM 810-2140-005 avoids overinvesting in ultra-high-end hardware while ensuring performance that supports yield targets.

h2. Typical application scenarios

LAM 810-2140-005 excels in 14nm–28nm advanced mature semiconductor processes, with two high-value application scenarios standing out. In LAM 790 Series advanced etch tools for 14nm logic chip production, LAM 810-2140-005 maintains chamber pressure at 2×10⁻⁷ Torr ±1.2%—critical for etching narrow trenches (≤50 nm width) where pressure variation >±1.5% causes CD (critical dimension) deviation. By syncing with LAM MFCs (e.g., LAM 839-011025-1) to balance C₄F₈ gas inflow and pumping speed, LAM 810-2140-005 reduces etch CD variation by 40% vs. basic vacuum modules, boosting yield from 92% to 95.5%.

In LAM 2300 Series high-precision PE-ALD (Plasma-Enhanced Atomic Layer Deposition) for 28nm high-k dielectric films, LAM 810-2140-005 controls pressure at 8×10⁻⁸ Torr ±2.8%. The module’s dual sensors ensure stability even if the primary capacitance manometer drifts, avoiding film thickness variation that leads to transistor performance issues. Fabs using LAM 810-2140-005 in this scenario report 30% fewer film defects and 20% faster process setup, as the module’s OPC UA integration automates pressure calibration and data logging.

LAM 810-802901-317

h2. Related model recommendations

LAM 810-048219-019: Advanced vacuum control module (7nm–28nm compatibility) and upgrade option for LAM 810-2140-005; adds AI-driven fault prediction and leak localization for ultra-high-end processes.

LAM 810-059223-312: Mid-range predecessor of LAM 810-2140-005 (14nm–45nm compatibility); offers single-sensor redundancy and lower sampling rate, suitable for fabs focused on 28nm–45nm.

LAM 839-011025-1: High-precision MFC (mass flow controller) paired with LAM 810-2140-005; syncs gas flow with vacuum pressure to maintain process consistency in etch/deposition.

LAM 718-094756-081: Wafer temperature control module compatible with LAM 810-2140-005; coordinates thermal control and vacuum pressure to optimize film uniformity in deposition.

LAM 796-220745-001: RF module for LAM etch tools, works with LAM 810-2140-005 to adjust plasma power based on real-time vacuum pressure, enhancing etch selectivity.

LAM 715-443130-001: Wafer edge temperature compensation module; pairs with LAM 810-2140-005 to ensure global process stability (vacuum + thermal) in 14nm–28nm deposition.

LAM 810-2140-CAL: Calibration kit exclusive to LAM 810-2140-005; includes NIST-traceable vacuum standards and software to maintain ±1.2% accuracy, extending calibration intervals to 18 months.

h2. Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 810-2140-005, confirm compatibility with the target LAM tool (790 Series/2300 Series) and update LAM PCS to v6.0+ if needed. Ensure the installation area meets environmental requirements (15°C–45°C, 5–85% RH) and has ≥15cm clearance from heat sources (e.g., RF generators) to avoid sensor interference. Use the included anti-vibration brackets for DIN rail or panel mounting, and torque vacuum line fittings (1/4” VCR) to 12 in-lbs ±1 in-lb with a calibrated torque wrench. Verify the 24 VDC power supply has a dedicated 3A circuit with surge protection, and avoid sharing power with high-noise components.

Maintenance suggestions: Perform daily checks via LAM PCS to review LAM 810-2140-005’s pressure setpoint vs. actual (tolerance ±1.2%/±2.8% per range) and sensor health. Weekly, inspect vacuum fittings for leaks using a helium detector (target ≤1×10⁻¹⁰ SCCM) and clean sensor ports with UHV-compatible isopropyl alcohol (99.999% purity). Every 18 months, calibrate LAM 810-2140-005 with the LAM 810-2140-CAL kit to maintain accuracy. Replace Viton® seals every 24 months (or if leaks are detected) to prevent vacuum degradation. Keep a spare capacitance manometer on hand for critical lines—replacement takes <1 hour, minimizing downtime.

h2. Service and guarantee commitment

LAM Research backs LAM 810-2140-005 with a 2.5-year standard warranty, covering defects in materials and workmanship for 14nm–28nm semiconductor applications. This warranty includes free replacement of faulty components (e.g., sensors, control boards) and 24/7 technical support via the LAM Customer Portal or email—ensuring fast resolution of issues that could impact production.

For extended protection, customers can purchase LAM’s Advanced Mature Node Support Plan, which extends coverage to 4 years and includes annual on-site calibration, priority technical support (≤4-hour response time), and 20% discounted replacement parts. All LAM 810-2140-005 units undergo 72-hour pre-shipment testing (pressure stability, sensor redundancy, communication functionality) to ensure reliability in 24/7 fab operations. LAM’s commitment to quality ensures LAM 810-2140-005 delivers consistent performance that supports long-term yield and productivity goals.