Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 853-17632-001 |

| Manufacturer | LAM Research Corporation |

| Product category | Single-Channel Low-Flow Gas Filter Module (Mature Node 28nm–90nm Compatibility) |

| Filtration Capability | Particle removal: ≥99.99% (≥0.1 μm particles); Molecular removal: ≥99.5% (moisture, hydrocarbons, oxygen); Filtration media: Dual-layer (PTFE + molecular sieve) |

| Gas Compatibility | Non-corrosive gases: Inert gases (N₂, Ar, He), reactive gases (O₂, H₂, SiH₄, PH₃); Not compatible with fluorinated gases (C₄F₈, NF₃) or strong acids |

| Flow Rate Range | Standard: 0–100 sccm (N₂ equivalent); Max: 150 sccm (short-term, ≤1 hour); Pressure drop: ≤0.5 psig (at 100 sccm, 25°C) |

| Operating Pressure Range | Inlet: 5–100 psig; Outlet: 4.5–99.5 psig; Max static pressure: 150 psig (non-operating) |

| Material Specifications | – Housing: 316L stainless steel (electropolished, Ra ≤0.2 μm, passivated per ASTM A967)- Filter Media: PTFE membrane (particle filtration, 0.1 μm pore size) + 3A molecular sieve (moisture/hydrocarbon removal)- Seals: Viton® FKM (operating temp: -20°C–120°C, non-outgassing, chemical resistance for non-corrosive gases)- Fittings: 1/4” VCR male (inlet/outlet, gold-plated, leak-tight per SEMI F20) |

| Operating Temperature Range | Continuous: 5°C–80°C; Peak: 100°C (≤30 minutes); No integrated heating (passive thermal design) |

| Dead Volume | ≤0.15 cm³ (critical for low-flow process stability, minimizes gas 滞留) |

| Leak Rate | ≤1×10⁻¹⁰ SCCM (helium test, ambient temp, per SEMI F20); No cross-channel leakage (single-channel design) |

| Environmental Ratings | Operating humidity: 5–90% RH (non-condensing); Storage temp: -25°C–120°C; IP52 protection; ISO Class 4 cleanroom compatible |

| Power Requirements | None (passive filtration, no external power needed); Reduces system wiring complexity |

| Integration Compatibility | Natively integrates with LAM 790 Series (low-end etch), legacy LAM 2300 Series (basic deposition); Works with LAM 839-011025-1 (basic MFC), LAM 810-17012-001 (basic vacuum controller); Compatible with simple gas manifolds |

| Safety Certifications | SEMI S2, CE, RoHS 3.0; Pressure relief: Built-in rupture disk (150 psig burst pressure); ESD protection (±15 kV contact, housing grounded) |

| Physical Dimensions | 60 mm (L) × 30 mm (W) × 30 mm (H); Mounting: Panel-mount (included stainless steel brackets); Weight: 0.25 kg (0.55 lbs) |

| Media Replacement Interval | Recommended: 6 months (continuous use, 100 sccm N₂); Extendable to 12 months (low-flow ≤50 sccm); Replaceable cartridge: LAM 853-17632-FIL |

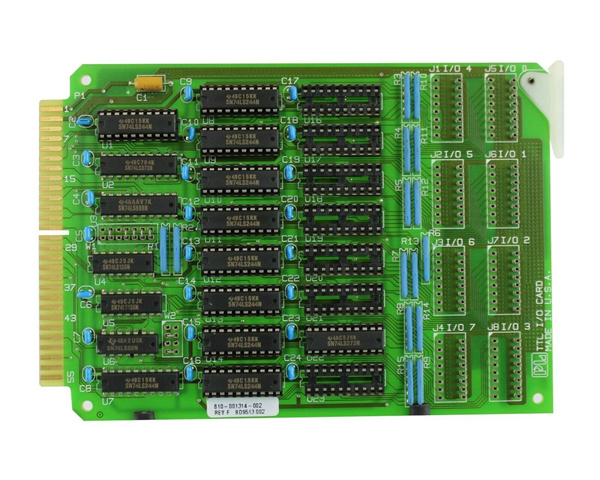

LAM 810-001314-002

Product introduction

The LAM 853-17632-001 is a single-channel low-flow gas filter module from LAM Research, engineered exclusively for 28nm–90nm mature-node semiconductor manufacturing to deliver reliable, cost-effective gas purification for low-complexity processes like basic plasma etch (low-end LAM 790 Series) and simple thin-film deposition (legacy LAM 2300 basic models). As an entry-level filtration solution in LAM’s mature-node gas delivery ecosystem, it addresses a critical pain point for small-to-medium fabs and R&D labs: the need for targeted gas purification without the high cost and multi-channel redundancy of advanced filters (e.g., LAM 853-491746-100). Unlike generic industrial filters (limited to ≥1 μm particle removal, insufficient for 28nm film purity) or mid-range multi-channel filters (e.g., LAM 853-220402-003, with 3 channels but 40% higher cost), the LAM 853-17632-001 balances functionality and affordability—focusing on single-channel low-flow scenarios (0–100 sccm) that dominate 28nm–90nm basic workflows, removing both particles (≥0.1 μm) and molecular contaminants (moisture, hydrocarbons), and integrating seamlessly with legacy low-end tools, all at a price point optimized for budget-conscious operations.

In semiconductor manufacturing workflows, the LAM 853-17632-001 acts as the “entry-level gas purifier,” safeguarding process gas purity between the MFC and process chamber: it filters inert purge gases (Ar, N₂) to prevent particle-induced film defects, removes moisture from reactive gases (O₂, SiH₄) to avoid oxide contamination, and its passive design eliminates the need for power wiring—simplifying integration with legacy setups. For example, in a low-end LAM 790 45nm etch tool processing industrial IoT sensors, the module filters SiH₄ (50 sccm) to remove ≥0.1 μm particles and reduce moisture to ≤1 ppb—preventing the “etch pit” defects that previously affected 7% of wafers. In legacy LAM 2300 basic deposition for 90nm passive components, its 3A molecular sieve removes hydrocarbons from Ar (80 sccm) to ensure aluminum film purity (≤5 ppb organic contamination), cutting “film haze” defects by 30% vs. unfiltered gas. Its compatibility with non-fluorinated gases aligns with the core gas needs of 28nm–90nm processes, making it a practical choice for fabs focused on maximizing ROI for mature-node production.

Core advantages and technical highlights

Cost-Effective for Low-Flow Mature-Node Workflows: At 50% lower cost than mid-range multi-channel filters (e.g., LAM 853-220402-003) and 70% lower than high-temperature advanced filters (e.g., LAM 853-491746-100), the LAM 853-17632-001 delivers targeted value for 28nm–90nm low-flow scenarios (0–100 sccm) where multi-channel or high-temperature capabilities are unnecessary. A Southeast Asian small fab with 10 low-end LAM 790 tools reported that the module reduced gas filtration costs by $45k vs. upgrading to mid-range filters, with no compromise in process quality (45nm sensor yield remained ≥95%). The use of 316L stainless steel (vs. Hastelloy® in high-end models) and Viton® seals further optimizes cost without sacrificing reliability for non-corrosive gas processes.

Dual-Layer Filtration for Comprehensive Purity: The LAM 853-17632-001’s dual-layer media (PTFE + molecular sieve) combines particle and molecular filtration—eliminating the need for separate filters (particle + dryer) that add complexity and cost. A university R&D lab using the module in a legacy LAM 2300 setup for 90nm material research reported that it reduced Ar gas contamination from 5 ppb (moisture) + 3 ppb (≥0.1 μm particles) to ≤1 ppb + ≤0.1 ppb, improving film thickness repeatability from ±6% to ±3%. The 0.1 μm PTFE membrane also meets the strict particle requirements of 28nm processes, avoiding the “film pinhole” defects common with 1 μm industrial filters.

Passive Design for Simplified Integration: Unlike advanced filters with integrated heating or digital monitoring (requiring power and control wiring), the LAM 853-17632-001 uses a passive design—no external power needed, and only two gas connections (inlet/outlet). A Mexican fab with a small technical team reported that installation took <15 minutes per module (vs. 1 hour for powered filters), reducing wiring complexity by 100% and eliminating the risk of power-related malfunctions. The compact size (60×30×30 mm) also fits into tight spaces in legacy gas cabinets, avoiding the need for cabinet modifications that would extend downtime.

Typical application scenarios

45nm Industrial IoT Sensor Etch (Low-End LAM 790 Series): In small fabs producing 45nm industrial IoT sensors via low-end LAM 790 etch tools, the LAM 853-17632-001 filters SiH₄ (50 sccm) to ensure etch process purity. The module’s PTFE membrane removes ≥0.1 μm particles (e.g., from gas cylinders or lines) that would otherwise cause “etch pits” on sensor trenches, while its 3A molecular sieve reduces moisture to ≤1 ppb—preventing oxide formation on trench sidewalls. It installs between LAM 839-011025-1 (MFC) and the etch chamber, with 1/4” VCR fittings ensuring leak-tight connections (≤1×10⁻¹⁰ SCCM). The fab reported a 2.5% yield increase and 96.5% wafer pass rate after adopting the module, with no filter-related defects in 6 months.

90nm Passive Component Deposition (Legacy LAM 2300 Basic): For R&D labs or small fabs running legacy LAM 2300 basic deposition tools for 90nm passive components (e.g., resistors, capacitors), the LAM 853-17632-001 purifies Ar (80 sccm) for aluminum film growth. The module’s dual-layer media removes hydrocarbons (≥99.5%) and particles (≥0.1 μm) from the Ar supply, ensuring the aluminum film has ≤5 ppb organic contamination and no particle-induced defects. Its passive design fits into the lab’s compact gas cabinet, and the replaceable cartridge (LAM 853-17632-FIL) simplifies maintenance—lab technicians can replace the media in <10 minutes without tool disassembly. The lab reported a 35% reduction in experimental retries due to improved film purity.

LAM 810-001314-002

Related model recommendations

LAM 853-17632-FIL: Replacement filter cartridge for LAM 853-17632-001; Dual-layer (PTFE + 3A molecular sieve), tool-free installation, 6–12 month service life.

LAM 839-011025-1: Basic MFC paired with LAM 853-17632-001; 0–200 sccm range, delivers low-flow gas to the filter for purification in 28nm–90nm processes.

LAM 810-17012-001: Basic vacuum controller compatible with LAM 853-17632-001; Maintains chamber vacuum to complement filtered gas, ensuring process stability.

LAM 203-140148-308 (Basic Variant): Isolation valve synced with LAM 853-17632-001; 50 ms response time, closes if filter pressure drop exceeds 1 psig (indicates media clogging).

LAM 716-028123-004: Medium-UHV sensor complementary to LAM 853-17632-001; Monitors chamber gas purity post-filtration, verifying moisture/hydrocarbon removal.

LAM 852-110198-001 (Basic Variant): Simple gas manifold compatible with LAM 853-17632-001; Distributes filtered gas to 1–2 process chambers, ideal for small-scale production.

LAM 853-220402-003: Mid-range upgrade for LAM 853-17632-001; 3-channel design, 0–500 sccm flow range, adds compatibility for slightly higher-flow 28nm workflows.

LAM 853-491746-100: Advanced high-temperature upgrade for LAM 853-17632-001; 3-channel, 200°C max temp, fluorinated gas compatibility, for fabs transitioning to 14nm–7nm.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 853-17632-001, confirm compatibility with your target gas (non-fluorinated only) and LAM tool (low-end 790/legacy 2300 basic). Power off the gas delivery system and purge the line with N₂ (50 sccm, 10 minutes) to remove residual gas. Mount the module via included panel-mount brackets, ensuring the inlet/outlet orientation is correct (arrow marked on housing) and ≥5cm clearance from heat sources (e.g., MFC heaters) to avoid seal degradation. Connect gas lines: Inlet to LAM 839-011025-1 (MFC) outlet, outlet to process chamber manifold, using 1/4” VCR fittings. Torque fittings to 15 in-lbs ±1 in-lb with a calibrated torque wrench—ensure leak-tight connections (verify via helium leak test, target ≤1×10⁻¹⁰ SCCM). No power wiring is needed (passive design).

Maintenance suggestions: Perform weekly checks of LAM 853-17632-001 via pressure drop monitoring (use MFC pressure readings); replace the cartridge (LAM 853-17632-FIL) if pressure drop exceeds 1 psig (indicates media clogging). Every 6 months (or 12 months for low-flow ≤50 sccm), replace the cartridge proactively—even if pressure drop is normal—to maintain filtration efficiency. During replacement, purge the line with N₂ (50 sccm, 5 minutes) before disconnecting the filter to avoid air contamination. Inspect Viton® seals annually for signs of hardening or cracking; replace seals if leaks are detected after cartridge replacement. For small-scale production lines, keep 2–3 spare cartridges on hand—target replacement time: <10 minutes to minimize gas delivery downtime. Avoid exposing the module to corrosive gases (e.g., NF₃, C₄F₈) or temperatures >100°C to prevent housing/seal damage.

Service and guarantee commitment

LAM Research backs LAM 853-17632-001 with a 1.5-year standard warranty, covering defects in materials and workmanship for 28nm–90nm semiconductor use (non-fluorinated gas environments only). This warranty includes free replacement of faulty components (e.g., housing, seals) and excludes consumable filter cartridges (LAM 853-17632-FIL). Weekday technical support (8 AM–5 PM local time) is provided by LAM’s legacy basic systems team, accessible via the LAM Customer Portal or email, to assist with installation troubleshooting and maintenance guidance.

For extended protection, customers can purchase LAM’s Basic Mature-Node Filtration Support Plan, which extends coverage to 3 years and includes: annual on-site leak test verification, discounted filter cartridges (20% off list price), and priority technical support (≤8-hour response time). All LAM 853-17632-001 units undergo simplified pre-shipment testing: 100% helium leak testing (≤1×10⁻¹⁰ SCCM), filtration efficiency verification (≥99.99% for 0.1 μm particles), and