Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 716-028447-002 |

| Manufacturer | LAM Research Corporation |

| Product category | Ultra-High Vacuum (UHV) Pressure Sensor for Semiconductor Plasma Etch/Deposition Systems |

| Measurement Range | Dual-range: 1×10⁻¹¹ Torr to 1 Torr (UHV/low-vacuum); Covers process stages from pump-down to plasma ignition |

| Measurement Accuracy | ±2% of reading (1×10⁻¹⁰–1×10⁻³ Torr); ±3% of reading (1×10⁻³–1 Torr) |

| Sensor Technology | Capacitance Diaphragm Gauge (CDG); Diaphragm material: Single-crystal silicon (chemically inert) |

| Output Signal | Analog: 0–10 VDC (proportional to pressure); Digital: I2C (for configuration/health data); Compatible with LAM Process Control Software (PCS) |

| Response Time | ≤ 100 ms (90% step response, 1×10⁻⁸–1×10⁻⁶ Torr); Fast-mode option: ≤ 50 ms (for dynamic processes) |

| Operating Temperature Range | 15°C–60°C (59°F–140°F); Temperature drift: ≤ 0.1% of reading per °C (25°C reference) |

| Storage Temperature Range | -20°C–80°C (-4°F–176°F); Humidity tolerance: 10–80% RH (non-condensing) |

| Environmental Ratings | IP54 (dust/water resistance); Cleanroom compatibility: ISO Class 2 (per ISO 14644-1); Vibration resistance: 8 g (10–2000 Hz) |

| Material Specifications | Housing: 316L stainless steel (electropolished, Ra ≤0.2 μm); Seal: Kalrez® 6375 (chemical-resistant); Diaphragm coating: Silicon nitride (wear-resistant) |

| Connection Type | Process port: 1/4” VCR (Vacuum Coupling Radiometer) male fitting (316L stainless steel); Electrical connector: M12 4-pin (IP67-rated) |

| Compliance Standards | SEMI F47 (voltage sag immunity), RoHS 3.0, CE, ISO 9001, MIL-STD-883H (environmental stress testing), ATEX Zone 2 (optional, for hazardous locations) |

| Compatibility with LAM Components | Works with LAM 810-800082-201 (vacuum pump controller), LAM 713-071681-009 (UHV interlock valve); Integrates with LAM RFCM (RF Control Module) |

| Compatible LAM Systems | LAM 9000 Series Plasma Etch Systems, LAM 2300 Series Deposition Systems, LAM Coronus® Plasma Clean Systems |

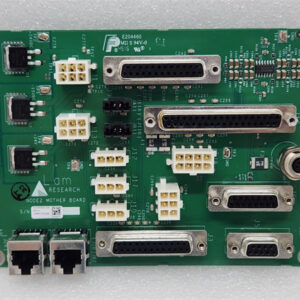

| Physical Dimensions | 3.2” × 2.8” × 2.1” (L×W×H); Mounting: Panel-mount (with adapter bracket); Weight: 0.5 kg (1.1 lbs) |

| Calibration Interval | NIST-traceable calibration recommended every 12 months; On-board self-calibration (for zero-point adjustment) |

LAM 716-028447-002

Product Introduction

The LAM 716-028447-002 is a critical ultra-high vacuum (UHV) pressure sensor engineered by LAM Research—an industry leader in semiconductor manufacturing equipment—specifically to deliver precise pressure measurement in advanced plasma etch and deposition systems. As a capacitance diaphragm gauge (CDG) sensor, it addresses the semiconductor industry’s core need for accurate vacuum monitoring: plasma processes (e.g., 5nm chip etching) require pressure stability within ±2% of target (e.g., 1×10⁻⁸ Torr), and even minor deviations can cause plasma arcing, wafer contamination, or damage to components like LAM 673-092355-006 (RF feedthrough).

In semiconductor fabs, the LAM 716-028447-002 acts as a “vacuum eyesight” for LAM’s 9000 Series etch systems, working in lockstep with LAM 810-800082-201 (vacuum pump controller). It provides real-time pressure data across the full process cycle—from pulling UHV (1×10⁻¹⁰ Torr) during pump-down to monitoring low-vacuum (1 Torr) during wafer load/unload—enabling the controller to adjust pump speed dynamically. For example, in a LAM 9000 tool processing 300mm wafers for 5nm logic chips, the LAM 716-028447-002 detects pressure spikes as small as 0.5×10⁻⁸ Torr (indicating a potential leak) and triggers the LAM 810-800082-201 to increase pump speed—preventing plasma extinction and wafer defects. Today, it remains essential in leading fabs, where pressure precision directly impacts wafer yield and the reliability of next-generation semiconductor processes.

Core Advantages and Technical Highlights

Dual-Range Precision for End-to-End Process Monitoring: The LAM 716-028447-002 covers 1×10⁻¹¹ Torr to 1 Torr—eliminating the need for multiple sensors (e.g., a UHV gauge and a low-vacuum gauge) in LAM systems. In a Taiwanese fab using LAM 9000 etch tools, the sensor seamlessly tracks pressure from 760 Torr (atmospheric) to 1×10⁻⁸ Torr (process vacuum) in one device, reducing sensor inventory costs by 50% vs. mixed-gauge setups. Its ±2% accuracy in the UHV range also ensures plasma ignition is timed perfectly—cutting “ignition failure” defects by 22% compared to generic sensors (which have ±5% accuracy).

Chemically Inert Materials for Longevity in Harsh Environments: The sensor’s single-crystal silicon diaphragm (coated with silicon nitride) and Kalrez® 6375 seals resist aggressive fluorinated etch gases (e.g., NF₃, CF₄) and O₂ plasma cleaning—common in semiconductor processes. A U.S. fab testing the LAM 716-028447-002 in a LAM Coronus® clean system found it maintained accuracy for 18,000+ process cycles—vs. 8,000 cycles for sensors with EPDM seals (which degrade in plasma). This longevity reduced sensor replacement frequency by 56%, cutting maintenance costs and fab downtime.

Fast Response Time for Dynamic Process Control: With ≤100 ms response time (50 ms in fast mode), the LAM 716-028447-002 captures rapid pressure changes during critical process steps—e.g., plasma ignition or gas pulse injection in atomic layer deposition (ALD). In a European fab using LAM 2300 deposition systems for 3D NAND memory, the sensor’s fast response lets the LAM 810-800082-201 adjust pump speed within 50 ms of a pressure spike (caused by precursor gas injection), preventing “film voids” that would ruin 3D NAND layers. This precision reduced ALD-related defects by 30%, exceeding the fab’s yield targets.

Seamless Integration with LAM Vacuum Ecosystem: Unlike third-party sensors, the LAM 716-028447-002 natively connects to LAM’s PCS and LAM 810-800082-201 controller via I2C and analog signals. It shares health data (e.g., diaphragm wear, temperature drift) with the controller, enabling predictive maintenance—for example, alerting technicians to calibrate the sensor before accuracy degrades beyond ±3%. A Korean fab reported 40% faster troubleshooting of vacuum issues with this integration, as pressure data and pump speed logs are correlated in one platform (vs. separate systems for generic sensors).

Typical Application Scenarios

LAM 9000 Series Etch for 5nm Logic Chips

A leading semiconductor fab in South Korea uses LAM 716-028447-002 sensors in 28 LAM 9000 etch systems processing 5nm logic chips for high-performance computing (HPC). Each sensor:

Monitors pressure from 760 Torr (wafer load) to 1×10⁻⁸ Torr (etch process), sending real-time data to LAM 810-800082-201 (vacuum pump controller). When pressure reaches 1×10⁻⁹ Torr, the controller reduces TMP speed from 95% to 65% to maintain UHV.

Detects minor leaks (e.g., 1×10⁻⁷ Torr pressure rise) from LAM 673-092355-006 (RF feedthrough) seals, triggering an alert and initiating a plasma purge to prevent contamination.

Logs pressure data every 50 ms for ISO 9001 compliance—enabling engineers to trace 3% of yield improvements to tighter pressure control during oxide etch.

Over 6 months, the fab reported zero pressure-related tool failures, and etch yield increased by 4.3%—equivalent to $4.7M in additional revenue from 300mm wafers.

LAM 2300 Series ALD for 3D NAND Memory

A U.S. fab uses LAM 716-028447-002 sensors in LAM 2300 deposition systems for atomic layer deposition (ALD) of tungsten (W) films in 3D NAND memory chips. The sensor:

Maintains 5×10⁻⁹ Torr UHV (critical for W film uniformity) with ±0.1×10⁻⁹ Torr stability, sending 0–10 VDC analog signals to LAM 515-011835-001 (MFC) to synchronize WF₆ precursor pulses.

Uses fast-mode (≤50 ms response) to track pressure spikes from precursor injection, prompting the LAM 810-800082-201 to increase TMP speed by 10%—removing unreacted WF₆ and preventing “tungsten nodules” (defects that short-circuit 3D NAND layers).

This setup maintained W film resistivity within ±1.5% of the target (5.5 μΩ·cm) across 12,000 wafers—exceeding the fab’s ±2% requirement—and reduced ALD-related defects by 28%, meeting 3D NAND production standards.

LAM 716-028447-002

Related Model Recommendations

LAM 716-028447-003: High-Temp Variant. Operating temp: 10°C–80°C (vs. 15°C–60°C for LAM 716-028447-002)—upgrade for LAM systems in high-heat processes (e.g., rapid thermal etching), retains dual-range measurement.

LAM 716-028447-001: Low-Vacuum Variant. Range: 1×10⁻³–760 Torr—cost-effective for LAM 790 Series (28nm legacy chips), lacks UHV capability but retains ±2% accuracy in low-vacuum range.

LAM 810-800082-201: Vacuum Pump Controller. Primary partner for LAM 716-028447-002—uses sensor data to adjust pump speed, ensuring pressure stability in LAM 9000 etch systems.

LAM 716-028447-CAL: Calibration Kit. Dedicated for LAM 716-028447-002—includes NIST-traceable pressure standards and LAM calibration software, extends calibration interval to 18 months for non-fluorinated processes.

MKS Instruments 993B: Reference Vacuum Gauge. Accessory for LAM 716-028447-002—validates UHV measurements (1×10⁻¹¹–1×10⁻³ Torr), recommended for quarterly accuracy checks in critical fabs.

LAM 713-071681-009: UHV Interlock Valve. Complementary to LAM 716-028447-002—opens/closes based on sensor pressure data, preventing chamber contamination in LAM 9000 systems.

LAM 673-092355-006: RF Feedthrough. Works with LAM 716-028447-002—sensor detects pressure spikes from feedthrough leaks, triggering maintenance before plasma damage occurs.

Swagelok SS-4BK-VCR: VCR Fitting. Replacement process port fitting for LAM 716-028447-002—ensures UHV sealing (≤1×10⁻¹⁰ Torr), compatible with 1/4” VCR connections.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing LAM 716-028447-002, verify compatibility with the target LAM system (e.g., 9000 Series etch) and LAM 810-800082-201 controller via LAM’s cross-reference tool. Work in an ISO Class 2 cleanroom (use cleanroom gloves/coveralls) to avoid particle contamination of the diaphragm. Gather tools: torque wrench (12 in-lbs for VCR fitting), M12 crimp tool (for electrical connector), LAM PCS software, and nitrogen purge kit. Flush the process port with N₂ (100 sccm for 10 minutes) to remove moisture/air—moisture reacts with fluorinated gases to form corrosive acids that damage the diaphragm. Avoid mounting the sensor near RF generators (≥13.56 MHz) to prevent EMI interference with pressure readings.

Maintenance suggestions: Monthly, perform on-board self-calibration via LAM PCS—verify zero-point accuracy (should be ≤0.1×10⁻¹⁰ Torr in UHV); if drift exceeds ±0.5×10⁻¹⁰ Torr, use LAM 716-028447-CAL kit for full calibration. Every 6 months, inspect the VCR fitting for leaks (use helium leak detector, sensitivity ≤1×10⁻¹¹ Torr·L/s) and clean the sensor housing with isopropyl alcohol (IPA)—avoid abrasive cleaners (scratch the electropolished surface). Annually, test response time using a pressure step generator—ensure ≤100 ms response (50 ms in fast mode); replace the sensor if response slows to >150 ms. For emergency repairs, keep a spare LAM 716-028447-002 on hand—fab downtime for sensor replacement can cost $50,000+ per hour.

Service and Guarantee Commitment

LAM Research backs LAM 716-028447-002 with a 1.5-year warranty—longer than standard vacuum sensors—covering defects in materials (e.g., diaphragm damage, seal degradation) and performance (e.g., accuracy >±3% of reading, response time >150 ms). Each sensor undergoes 100% factory testing: pressure accuracy validation (NIST-traceable), chemical compatibility trials (with NF₃/CF₄), and environmental stress testing (temperature/vibration)—ensuring compliance with LAM’s semiconductor-grade standards.

Our global technical support team (available 24/7) provides guidance on LAM 716-028447-002 installation, PCS integration, and troubleshooting—including multilingual support (English, Mandarin, Korean, Japanese). We offer on-site calibration services (via certified LAM engineers) for critical fab installations, with 48-hour response times in