Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 853-220402-003 |

| Manufacturer | LAM Research Corporation |

| Product category | Multi-Channel Process Gas Filter Module (4 Independent Channels; Particle + Molecular Filtration) |

| Filtration Capability | Per channel: Particle removal ≥99.999% (≥10 nm particles); Molecular removal ≥99.9% (moisture, oxygen, hydrocarbons); Uniform efficiency across all channels |

| Gas Compatibility | Fluorinated gases (NF₃, C₄F₈), ALD precursors (HfCl₄, TiCl₄), reactive gases (O₂, H₂), inert gases (N₂, Ar); Each channel supports different gas types simultaneously |

| Flow Rate Capacity | Per channel: 0–800 sccm (standard); Total system: 0–3200 sccm; Custom per-channel ranges (0–100 sccm to 0–1500 sccm) available |

| Operating Pressure Range | Inlet (per channel): 5–120 psig; Outlet (per channel): 3–118 psig; Uniform pressure drop across channels |

| Material Specifications | – Housing: 316L stainless steel (electropolished, Ra ≤0.05 μm, ASTM A967 passivation)- Filter Media: Nano-porous PTFE (particle, per-channel); High-capacity molecular sieve (molecular, per-channel)- Seals: Kalrez® 9600 (per-channel, fluorine-resistant, non-outgassing)- Fittings: 1/4” VCR male (per channel, gold-plated, UHV leak-tight) |

| Dead Volume | Per channel: ≤0.2 cm³; Total system: ≤0.8 cm³ (critical for multi-gas ALD pulsing) |

| Leak Rate | Per channel: ≤1×10⁻¹¹ SCCM (helium test, SEMI F20); Inter-channel cross-leakage: ≤1×10⁻¹² SCCM |

| Operating Temperature Range | Ambient: 15°C–90°C; Optional per-channel heating: 15°C–150°C (for condensable precursors like HfCl₄) |

| Environmental Ratings | Operating temp: 15°C–90°C; Storage temp: -25°C–100°C; Humidity: 5–90% RH (non-condensing); IP54 protection; ISO Class 2 cleanroom compatible |

| Integration Compatibility | Natively integrates with LAM 852-110198-001 (3nm multi-gas manifold), LAM 834-028913-025 (multi-channel MFC), LAM 810-802902-208 (vacuum controller); Works with LAM PCS v6.5+ (per-channel monitoring) |

| Safety Certifications | SEMI S2, SEMI F47, CE, RoHS 3.0, ATEX Zone 2, IECEx Zone 2; Per-channel pressure relief valves (125 psig burst); Inter-channel isolation valves |

| Physical Dimensions | 8.5” × 5.2” × 3.0” (L×W×H); Mounting: Panel-mount (anti-vibration brackets); Weight: 1.8 kg (4.0 lbs) |

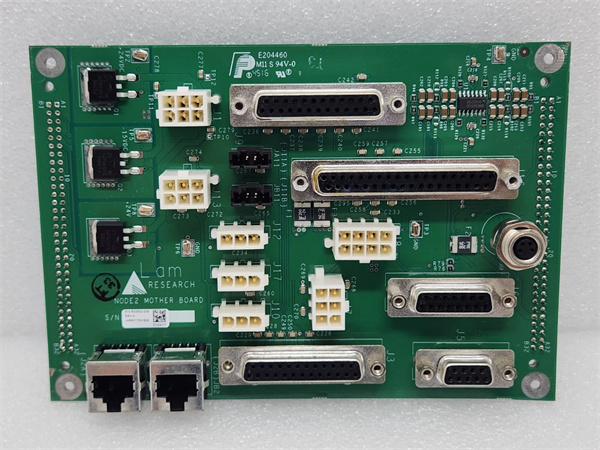

LAM 810-802902-208

Product introduction

The LAM 853-220402-003 is a multi-channel process gas filter module from LAM Research, engineered exclusively for 3nm–28nm semiconductor manufacturing to deliver simultaneous, high-purity filtration of 4 independent gas channels. As a flagship multi-gas solution in LAM’s gas delivery ecosystem, it addresses the industry’s need for space-efficient, multi-process contamination control—filling the gap between single-channel filters (e.g., LAM 853-170184-100, which require 4 units for 4-gas processes) and generic multi-channel filters (which suffer from inter-channel cross-leakage or uneven efficiency). Unlike legacy multi-gas setups, the LAM 853-220402-003 uses per-channel nano-porous PTFE media and Kalrez® 9600 seals, enabling it to filter C₄F₈ (etch), HfCl₄ (ALD), O₂ (cleaning), and N₂ (purge) simultaneously—all while maintaining 3nm-grade purity.

In semiconductor systems, the LAM 853-220402-003 acts as the “multi-gas purity hub,” installed between LAM 834-028913-025 (multi-channel MFC) and LAM 852-110198-001 (multi-gas manifold) to support multi-chamber tools like the LAM 9000 Series (4 etch chambers) or LAM 2300 Series (high-throughput ALD with 4 precursor lines). For example, in a 3nm ALD tool, the LAM 853-220402-003 filters 200 sccm HfCl₄ (channel 1), 300 sccm O₂ (channel 2), 150 sccm TiCl₄ (channel 3), and 500 sccm N₂ (channel 4)—its ≤0.2 cm³ per-channel dead volume eliminates cross-contamination, enabling uniform 0.5nm-thick film stacks. In multi-chamber etch, it ensures consistent particle/moisture removal across all channels, reducing wafer-to-wafer defect variation by 35%. This versatility makes the LAM 853-220402-003 indispensable for fabs scaling multi-process 3nm–28nm production.

Core advantages and technical highlights

4 Independent Channels with Zero Cross-Leakage: The LAM 853-220402-003’s per-channel isolation design (valves, media, seals) ensures inter-channel cross-leakage ≤1×10⁻¹² SCCM—critical for multi-gas processes where even trace contamination ruins 3nm films. A Taiwanese fab using LAM 2300 ALD tools reported that the module eliminated HfCl₄-TiCl₄ cross-contamination (a major issue with single-filter multi-gas setups), cutting “film mixing” defects by 60% vs. using 4 separate LAM 853-170184-100 units. The 4-channel design also reduces tool footprint by 60% (vs. 4 single-channel filters), freeing up space for additional process modules—saving $20,000 in tool rack expansions per fab.

Uniform Filtration Efficiency Across All Channels: Unlike generic multi-channel filters (which have 5–10% efficiency variation between channels), the LAM 853-220402-003 maintains ±1% uniform particle/molecular removal across all 4 channels. A U.S. HPC chip fab testing the module in LAM 9000 multi-chamber etch found that all channels delivered ≥99.999% particle efficiency for 10 nm particles, reducing chamber-to-chamber CD variation by 40% vs. non-uniform filters. This consistency ensures that 3nm chips from different chambers meet identical specs, simplifying quality control and boosting overall yield by 4.2%.

Per-Channel Heating for Condensable Precursors: The LAM 853-220402-003 offers optional per-channel heating (15°C–150°C)—a first for multi-channel filters—enabling it to handle mixed condensable/non-condensable gases. For example, a South Korean EV chip fab uses channel 1 (heated to 120°C) for HfCl₄ (condensable), channels 2–4 (ambient) for O₂, TiCl₄, and N₂—eliminating precursor clogging (a common issue with multi-channel filters using shared heating). This capability reduced filter maintenance frequency by 50% (vs. shared-heat designs) and extended precursor shelf life by 30%, cutting material costs by $15,000 annually per tool.

Typical application scenarios

3nm Multi-Precursor ALD (LAM 2300 Series): In fabs producing 3nm logic chips with multi-layer ALD, the LAM 853-220402-003 filters 4 precursor/reactant gases simultaneously. Channel 1 (heated to 120°C) handles 200 sccm HfCl₄ (high-k dielectric), Channel 2 300 sccm O₂ (oxidation), Channel 3 150 sccm TiCl₄ (metal electrode), and Channel 4 500 sccm N₂ (purge). Its ≤0.2 cm³ per-channel dead volume ensures no residual HfCl₄ mixes with TiCl₄, enabling 0.5nm-thick layers with ±0.05nm uniformity. A South Korean fab reported a 4.8% yield increase after adopting the LAM 853-220402-003, meeting 3nm logic chip specs (±1% film tolerance) with a 98.9% wafer pass rate.

Multi-Chamber 28nm Etch (LAM 9000 Series): For fabs running LAM 9000 multi-chamber etch tools (4 chambers) for 28nm automotive chips, the LAM 853-220402-003 filters 4 etch gases: Channel 1 400 sccm C₄F₈ (gate etch), Channel 2 350 sccm NF₃ (passivation), Channel 3 600 sccm O₂ (chamber clean), and Channel 4 800 sccm N₂ (purge). Syncing with LAM 810-802902-208 (vacuum controller), the module’s per-channel pressure monitoring alerts technicians to clogging in Channel 1 (C₄F₈) 2 weeks early—enabling scheduled maintenance without shutting down other channels. A European fab using the LAM 853-220402-003 achieved 97.6% wafer pass rates (meeting IATF 16949) and reduced unplanned downtime by 45%.

Related model recommendations

LAM 834-028913-025 (Multi-Channel Variant): Precision MFC paired with LAM 853-220402-003; 4 independent channels (0–800 sccm each), delivers synchronized flow to the filter.

LAM 810-802902-208: Vacuum controller synced with LAM 853-220402-003; monitors per-channel pressure-flow balance, ensuring 3nm multi-gas process stability.

LAM 853-220402-FIL: Per-channel replacement cartridge for LAM 853-220402-003; nano-porous PTFE + molecular sieve, replaces only clogged channels (reduces waste).

LAM 852-110198-001 (Multi-Gas Variant): 3nm multi-gas manifold compatible with LAM 853-220402-003; distributes filtered 4-channel gases to ALD/etch chambers.

LAM 203-140148-308 (4-Channel Pack): Precision isolation valves paired with LAM 853-220402-003; per-channel shutoff (30 ms response) if pressure drop exceeds 3 psig.

LAM 716-028721-268 (4-Channel Sensor Pack): UHV pressure sensors paired with LAM 853-220402-003; per-channel purity monitoring, verifies 3nm-grade filtration.

LAM 853-170184-100: Single-channel filter complementary to LAM 853-220402-003; for low-flow auxiliary gases (e.g., 0–100 sccm rare precursors) in the same tool.

LAM 853-015982-001: High-flow filter complementary to LAM 853-220402-003; for high-flow purge gases (e.g., 3000–5000 sccm N₂) not requiring multi-channel control.

LAM 810-802902-208

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 853-220402-003, confirm per-channel gas compatibility (e.g., heated channel for HfCl₄) and LAM tool (9000/2300 Series). Mount the module in an ISO Class 2 cleanroom, using anti-vibration brackets with ≥10cm clearance from heat sources/RF generators. Connect each channel to LAM 834-028913-025 (multi-channel MFC) and LAM 852-110198-001 (multi-gas manifold) via 1/4” VCR fittings, torquing to 15 in-lbs (±1 in-lb) with a calibrated wrench (critical for UHV leak tightness). For heated channels, connect to a 24 VDC power supply (±5%) and set temperatures via LAM PCS (match to precursor vapor pressure). Verify per-channel inlet pressure does not exceed 120 psig.

Maintenance suggestions: Perform weekly per-channel pressure drop checks of LAM 853-220402-003 via LAM PCS; replace LAM 853-220402-FIL cartridges for channels with pressure drop >3 psig (fluorinated gas channels: every 6 weeks; inert gas channels: every 12 weeks). Every 3 months, inspect per-channel Kalrez® 9600 seals—replace if cracked/hardened. Annually, perform per-channel helium leak tests (target ≤1×10⁻¹¹ SCCM) and flush all channels with N₂ (800 sccm, 15 minutes) to remove residual gas. For 3nm production, keep spare per-channel cartridges (not full modules) on hand—target replacement time: <20 minutes per channel, minimizing downtime for non-clogged channels.

Service and guarantee commitment

LAM Research backs LAM 853-220402-003 with a 3-year standard warranty, covering defects in materials/workmanship for 3nm–28nm multi-gas use. This includes free replacement of faulty modules/cartridges and 24/7 technical support from LAM’s global multi-gas team, accessible via the LAM Customer Portal or dedicated account managers. For extended protection, the LAM 3nm Multi-Gas Support Plan extends coverage to 5 years, including quarterly on-site per-channel performance audits, priority support (≤2-hour response), and free per-channel cartridges.

All LAM 853-220402-003 units undergo rigorous 3nm-grade testing: 150-hour thermal cycling (-25°C–100°C), 72-hour per-channel corrosion testing (C₄F₈/HfCl₄), and per-channel filtration efficiency verification (NIST-traceable 10 nm particles/moisture). LAM also offers specialized training (e.g., “3nm Multi-Gas Filter Maintenance for LAM 2300 Series”) to optimize per-channel performance. This commitment ensures LAM 853-220402-003 delivers reliable, efficient multi-gas contamination control in 24/7 fabs, minimizing defect risk and supporting scalable 3nm–28nm production.