Description

D633-317B: Product Overview

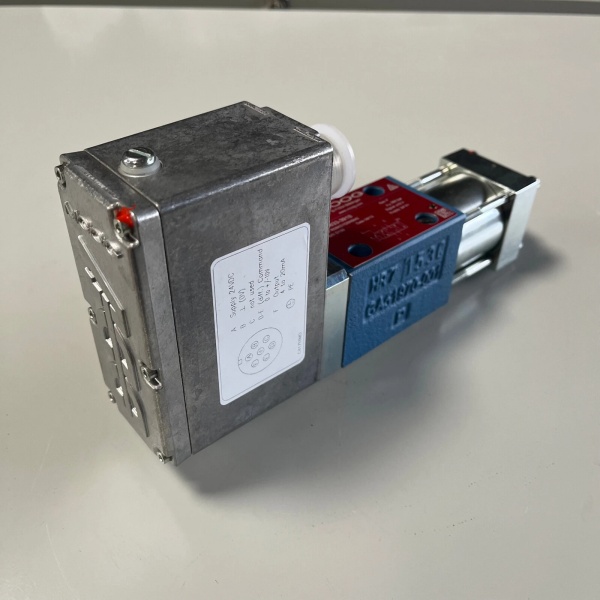

The D633-317B is a direct-drive electrohydraulic servo valve (DDV) engineered for precision control of hydraulic actuators in dynamic systems. Within an automation architecture, it serves as the critical interface between electronic controllers (e.g., PLCs, motion controllers) and hydraulic actuators (cylinders, motors), converting low-power electrical command signals into proportional hydraulic flow and pressure to regulate actuator position, velocity, or force.

This valve belongs to the D633 Series, a platform defined by its direct-drive architecture. Unlike traditional two-stage servo valves that rely on a pilot stage for signal amplification, the D633 Series uses a torque motor to actuate the spool directly. This design eliminates pilot-stage complexity, reduces response time, and enhances reliability by minimizing potential leak points and moving parts. The D633-317B is typically integrated into closed-loop control systems with position/force feedback, ensuring stable actuator behavior critical for high-accuracy applications. Its role is to provide deterministic, high-speed hydraulic modulation, making it suitable for scenarios requiring millisecond-level adjustments, such as small-scale robotics or laboratory test rigs. The D633 Series platform emphasizes compatibility with MOOG servo valve amplifiers (e.g., G631 series) and compact integration, reducing engineering effort for system designers.

Moog D633-481B

D633-317B: Technical Specifications

-

Model Number: D633-317B

-

Manufacturer: Moog Inc.

-

Product Type: Electrohydraulic Servo Valve (Direct-Drive/DDV)

-

Valve Configuration: 4-way spool (symmetrical flow paths, spring-centered)

-

Nominal Flow: 10 GPM (37.9 L/min) @ 1000 psi (69 bar) differential pressure

-

Maximum Pressure: 3000 psi (207 bar) per port

-

Input Signal: ±10VDC (standard), ±40mA (via optional G631 series amplifier)

-

Response Time: <5 ms (step input to 90% flow)

-

Resolution: <0.1% of full scale

-

Operating Temperature: -20°C to +80°C (fluid-dependent)

-

Fluid Compatibility: Petroleum-based oils (ISO VG 32/46), phosphate ester synthetic fluids

-

Weight: 2.0 kg (4.4 lbs, valve body only)

-

Dimensions: 140mm (L) x 76mm (W) x 102mm (H) (approximate)

-

Certifications: CE, ISO 9001, AS9100

Core Features & Customer Value

The direct-drive architecture of the D633-317B eliminates the pilot stage, reducing response time to under 5 milliseconds—substantially faster than two-stage valves. For engineers managing high-speed systems like small robotic arms or material testing rigs, this minimizes actuator lag, enabling precise control during rapid movements. The 10 GPM nominal flow provides adequate capacity for moderate-sized actuators, avoiding the complexity of multi-valve setups.

With resolution below 0.1% of full scale, the valve delivers linear, predictable output proportional to the ±10VDC input. This precision is critical in applications like low-frequency fatigue testing, where maintaining exact force profiles ensures valid data collection. The compact design, a byproduct of simplified mechanics, eases integration into space-constrained environments such as laboratory benchtops or mobile equipment.

The robust torque motor resists contamination better than pilot-operated designs, extending service life to 15,000+ operating hours with proper filtration. Native compatibility with Moog G631 amplifiers and standard analog controllers simplifies system integration, reducing setup time. For maintenance teams, the field-replaceable spool/sleeve assembly minimizes downtime during repairs. The spring-centered return mechanism ensures safe actuator positioning during power loss, enhancing system safety.

Moog D633-481B

Typical Applications

The D633-317B is applied in systems requiring moderate-flow, high-speed hydraulic control. In small industrial robotics, it manages joint actuators for pick-and-place arms, where its <5 ms response ensures positioning accuracy within ±0.1mm during repetitive tasks. Material testing laboratories use it in fatigue rigs applying cyclic loads up to 20 Hz, with its precision replicating real-world stress conditions for composite material evaluation.

Aerospace simulation platforms employ the valve to control auxiliary actuators in flight control simulators, providing realistic response for training systems. Manufacturing settings, such as small plastic injection molding machines, utilize it for precise clamp/unclamp sequencing, reducing cycle times through rapid, controlled movement. Its balance of flow capacity and speed also suits hydraulic presses for small-part forming, where accurate force application prevents material waste.