Description

T164-905A-10-C3-2-1A: Product Overview

The Moog T164-905A-10-C3-2-1A is a proportional control valve from the T Series, designed for electrohydraulic systems requiring precise flow and pressure regulation. In an automation architecture, it serves as the interface between electronic controllers (e.g., PLCs, PID controllers) and hydraulic actuators (e.g., cylinders, motors), converting low-power electrical command signals into proportional hydraulic outputs. The T Series is recognized for its stability in variable-load applications, making it suitable for industrial presses, material testing rigs, and mobile machinery where consistent actuator behavior is critical. This valve operates on a proportional solenoid pilot stage and a sliding spool main stage, ensuring linear response across its operating range. It is typically integrated into closed-loop systems with feedback from position/force sensors, adjusting output to maintain desired parameters—essential for avoiding overshoot in high-force applications like metal forming.

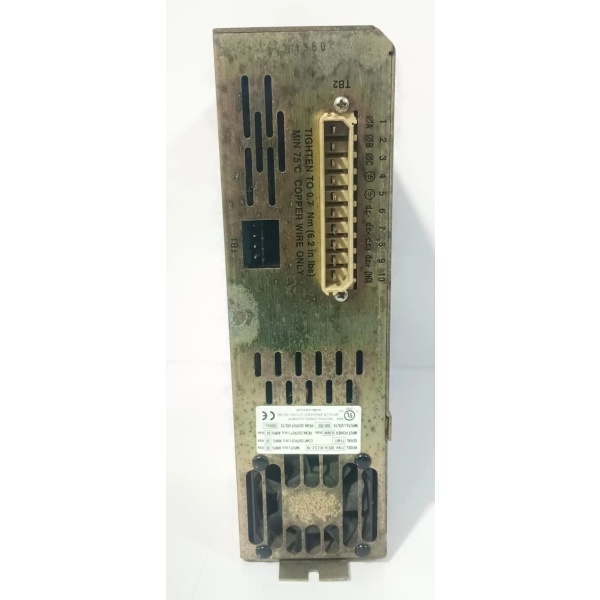

MOOG T164-905A-10-C3-2-1A

T164-905A-10-C3-2-1A: Technical Specifications

-

Model Number: T164-905A-10-C3-2-1A

-

Manufacturer: Moog Inc.

-

Product Type: Electrohydraulic Proportional Valve

-

Valve Configuration: 4-way 3-position spool (C3 configuration: tandem center, float detent)

-

Nominal Flow: 10 GPM (37.9 L/min) @ 1000 psi (69 bar) differential pressure

-

Maximum Pressure: 3000 psi (207 bar) per port

-

Input Signal: 4-20mA (standard), 0-10VDC (optional via jumper)

-

Response Time: <20 ms (step input to 90% flow)

-

Hysteresis: <0.5% of full scale

-

Operating Temperature: -20°C to +80°C (-4°F to 176°F)

-

Fluid Compatibility: Petroleum-based oils (ISO VG 32/46), HFC fluids (e.g., Houghto-Safe 620)

-

Weight: 2.1 kg (4.6 lbs, valve body only)

-

Dimensions: 178mm (L) x 102mm (W) x 76mm (H) (approximate)

-

Certifications: CE, ISO 9001 (manufacturing standard)

Core Features & Customer Value

Proportional Flow/Pressure Control: The valve’s spool position adjusts linearly with the input signal, delivering flow proportional to 4-20mA commands (e.g., 12mA = 50% max flow). For engineers, this enables precise actuator speed/force control in plastic injection molding machines, where ±2% flow accuracy prevents part defects.

Fast Dynamic Response: A <20 ms response time allows rapid adjustment during transient conditions (e.g., sudden load changes in a press brake). In material testing rigs, this minimizes lag between command and force application, ensuring accurate stress-strain data.

Durable Construction for Industrial Environments: The valve body is forged steel with a hardened spool, resisting wear from contaminated fluids (common in construction equipment). For maintenance teams, this extends service life to 8,000+ operating hours, reducing replacement costs.

Flexible Signal Compatibility: While optimized for 4-20mA, it accepts 0-10VDC inputs via internal jumpers—simplifying integration with analog controllers or upgraded digital systems (e.g., retrofitting a paper mill calender with modern PLCs).

Stable Performance Under Variable Loads: Internal pressure compensators maintain consistent flow output even as system pressure fluctuates by ±15%. In mobile hydraulic systems (e.g., excavator booms), this ensures smooth operation regardless of engine speed variations.

MOOG T164-905A-10-C3-2-1A

Typical Applications

The T164-905A-10-C3-2-1A is deployed in systems requiring proportional hydraulic control:

-

Industrial Presses: Metal stamping presses (ram force control), hydraulic presses (blank holder pressure regulation).

-

Test & Simulation: Material testing machines (tension/compression force control), fatigue test rigs (cyclic loading).

-

Mobile Machinery: Excavator boom/arm control, agricultural tractor hydraulic implements.

-

Manufacturing: Injection molding machines (clamp force adjustment), die-casting machines (shot velocity control).

In a metal stamping operation, for example, the valve regulates pressure to a 500-ton press, with its 4-20mA input linked to a PLC that adjusts force based on material thickness—reducing scrap by 10% through consistent part formation.