Description

G122-824A002: Product Overview

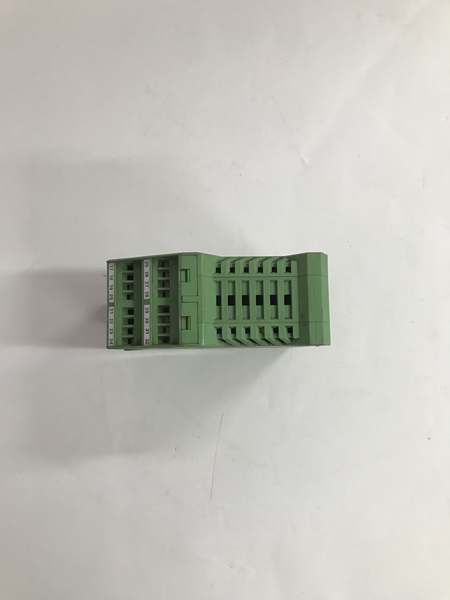

The Moog G122-824A002 is a servo valve amplifier from the G122 Series, designed to interface electronic controllers with Moog electrohydraulic servo valves. In an automation system, it serves as a signal conditioner and driver, converting low-power command signals (e.g., from PLCs, motion controllers) into the precise current outputs required to modulate servo valve spools. The G122 Series is recognized for its stability and compatibility with Moog’s D660/D661 series servo valves, forming the backbone of closed-loop hydraulic control in applications demanding micrometer-level positioning or force accuracy. This amplifier provides dual ±40mA outputs, enabling simultaneous control of two servo valves or redundant actuation systems. It incorporates built-in filtering (to reject EMI), current limiting (to protect valves), and thermal shutdown (for fault tolerance), ensuring reliable operation in industrial environments. Typical integration involves connecting the amplifier to a 24V DC power supply, receiving analog command signals, and outputting current to the servo valve’s torque motor—critical for maintaining actuator stability in dynamic systems like press brakes or flight simulators.

Moog G122-824A002

G122-824A002: Technical Specifications

-

Model Number: G122-824A002

-

Manufacturer: Moog Inc.

-

Product Type: Servo Valve Amplifier

-

Amplifier Class: Linear, dual-output

-

Input Signal: ±10VDC (standard), ±20mA (optional via jumper), 10kΩ input impedance

-

Output Signal: Dual ±40mA current outputs (independent channels), 0-500Ω load capability

-

Supply Voltage: 24V DC (±10%, 2A max current draw)

-

Gain Adjustment: 10-turn potentiometer per channel (0.5-2.0 mA/V)

-

Operating Temperature: 0°C to +60°C (32°F to 140°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Dimensions: 114mm (L) x 89mm (W) x 38mm (H) (DIN rail mountable)

-

Weight: 0.45 kg (1.0 lb)

-

Protection Features: Overcurrent limiting, thermal shutdown, reverse polarity protection

-

Certifications: CE, UL/cUL Listed, RoHS

Core Features & Customer Value

Dual-Channel Independent Control: The two ±40mA outputs allow simultaneous driving of two servo valves (e.g., for dual-acting cylinders) or redundant control paths. For engineers, this simplifies system design in applications like plastic injection molding machines, where separate valves control clamping and injection—eliminating the need for multiple amplifiers.

Precision Signal Conditioning: Built-in low-pass filtering (10Hz cutoff) removes high-frequency noise from controller outputs, while adjustable gain (0.5-2.0 mA/V) matches the amplifier to valve requirements. This ensures linear current output proportional to the input signal, critical for maintaining actuator positioning accuracy in metal stamping presses (±0.01mm tolerance).

Robust Fault Protection: Overcurrent limiting prevents damage to servo valve torque motors during short circuits, and thermal shutdown (at 85°C) safeguards against overheating in enclosed control cabinets. For maintenance teams, this reduces unplanned downtime—e.g., avoiding valve failure in a paper mill calender stack due to transient current spikes.

Seamless Moog Servo Valve Integration: Optimized for Moog D660/D661 series valves (e.g., D661-4651), the amplifier’s output impedance and response time (≤1ms) match valve dynamics. Plug-and-play compatibility with Moog’s G123 configuration software simplifies setup, allowing technicians to calibrate gains and offsets without oscilloscopes.

Compact DIN Rail Mounting: The small footprint (114x89mm) and DIN rail clips enable dense panel installation, ideal for retrofits in crowded control rooms. For procurement managers, this reduces cabinet space requirements and installation labor costs.

Moog G122-824A002

Typical Applications

The G122-824A002 is deployed in hydraulic systems requiring precise valve control:

-

Industrial Machinery: Plastic injection molders (clamp force/flow control), metal stamping presses (ram positioning), press brakes (bend angle accuracy).

-

Test & Simulation: Material testing machines (tension/compression control), wind tunnel actuators (vane positioning).

-

Aerospace: Flight simulator hydraulic actuators (pitch/roll control), landing gear deployment systems.

-

Manufacturing: Paper mill calenders (roller pressure control), textile looms (warp tension adjustment).

In a automotive parts stamping line, for example, the amplifier drives two D661-4651 servo valves to control a dual-acting cylinder—one valve for blank holder force, the other for punch stroke. Its fast response (<1ms) ensures the punch follows the programmed profile within ±0.02mm, reducing defective parts by 15%.