Description

Detailed Parameter Table

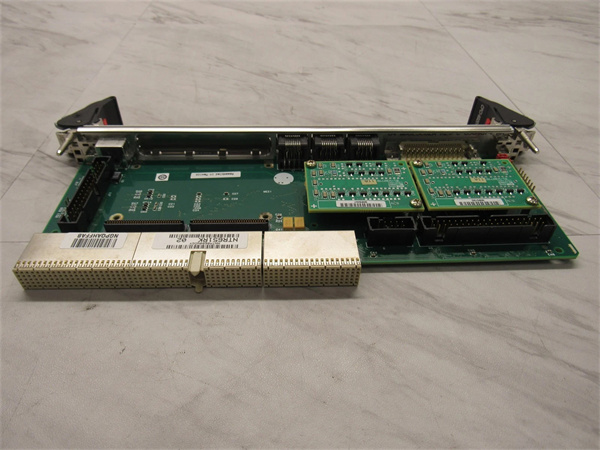

| Parameter name | Parameter value |

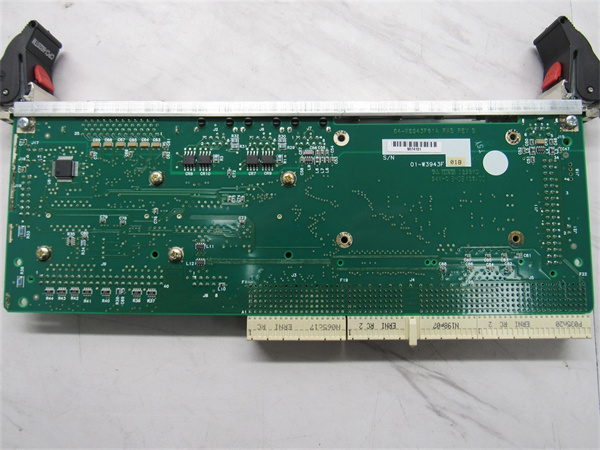

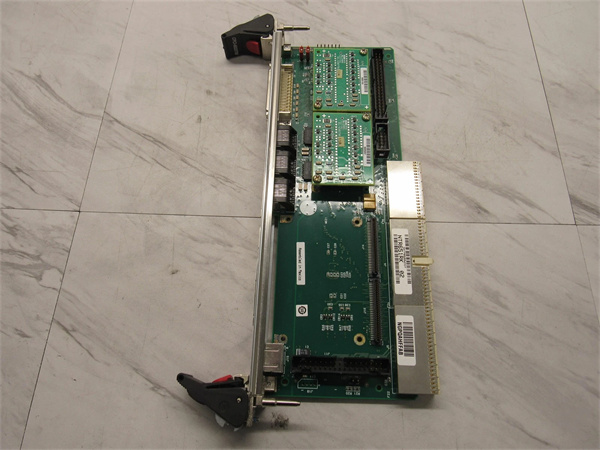

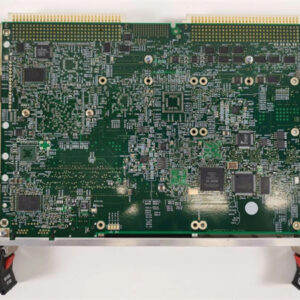

| Product model | Motorola CPCI-6020TM |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial CompactPCI (CPCI) Rugged Mid-Performance Single-Board Computer (SBC) |

| Processor | 1.0 GHz Intel Pentium M 735A processor; 2 MB L2 cache; 400 MHz FSB (Front-Side Bus); No FPU (integrated in Pentium M) |

| Memory Configuration | 512 MB DDR SDRAM (expandable to 2 GB, non-ECC); 40 GB 2.5-inch IDE hard drive (or optional 1 GB CompactFlash); 512 KB battery-backed SRAM (non-volatile) |

| Communication Interfaces | 2x 10/100/1000Base-T Gigabit Ethernet ports (RJ-45, IEEE 802.3); 2x RS-232/422/485 serial ports (software-configurable); 1x USB 2.0 port; 1x VGA video output (1280×1024 max resolution) |

| Expansion Interfaces | 3x 32-bit/64-bit CPCI peripheral slots (compliant with PICMG 2.0); 1x PC/104+ expansion connector (for legacy I/O modules); 1x IDE interface (for external storage) |

| Power Requirements | Input voltage: +5V DC (±5%) and +12V DC (±10%); Power consumption: Typical 15 W (25°C, no expansion); Maximum 25 W (2 GB RAM + 2 Ethernet active) |

| Environmental Ratings | Operating temperature: -40°C–70°C (-40°F–158°F); Storage temperature: -55°C–85°C (-67°F–185°F); Humidity: 5%–95% (non-condensing, 40°C dew point); Vibration: 10–2000 Hz, 3.0 g (rms); Shock: 100 g (peak, 1 ms); EMC Compliance: MIL-STD-461F (military), EN 61000-6-2 (industrial) |

| Physical Dimensions | 3U CPCI form factor: 100mm × 160mm × 25mm (3.94in × 6.30in × 0.98in); Weight: 550 g (1.21 lbs) |

| Diagnostic Features | LED indicators (power, CPU activity, Ethernet link/activity, hard drive status); Built-in hardware monitor (temperature, voltage); BIOS-based self-test (POST, 90% component coverage); Fault logging (non-volatile) |

| Compatible Peripherals | Motorola CPCI-7300 (8-channel analog I/O), Motorola CPCI-8200 (16-channel digital I/O), Motorola PC104-COM4 (4-port serial module), Emerson CPCI-PSU-300W (300W CPCI power supply) |

| Product Life Cycle | Discontinued/Obsolete |

MOTOROLA CPCI-6020TM

Product Introduction

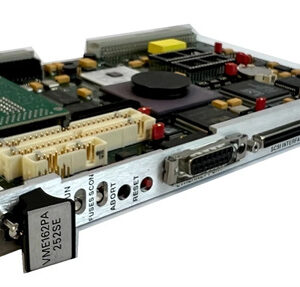

The Motorola CPCI-6020TM is a legacy industrial CompactPCI (CPCI) rugged mid-performance SBC designed for 2000s-era harsh-environment automation—filling the gap between entry-level CPCI modules (e.g., low-power 300 MHz processors) and high-end rugged SBCs (e.g., military-grade 2.0 GHz Xeon models). Unlike older VME-based SBCs like Motorola MVME162-210 (16 MHz MC68020, 16-bit VMEbus), Motorola CPCI-6020TM integrates a 1.0 GHz Pentium M processor, Gigabit Ethernet, and CPCI/PICMG 2.0 compliance—making it ideal for applications like military vehicle control, railway signaling, or offshore oil rig monitoring, where ruggedness, speed, and modular expansion are critical.

As a versatile rugged SBC in Motorola’s 2000s CPCI lineup, Motorola CPCI-6020TM acts as a “harsh-environment control hub.” It processes high-volume data from industrial sensors (via Motorola CPCI-7300 analog I/O) and communicates with remote systems via Gigabit Ethernet—all while withstanding extreme temperatures, vibration, and shock. For example, in a 2000s railway signaling system, Motorola CPCI-6020TM monitored track occupancy sensors (via Motorola CPCI-8200 digital I/O) and sent real-time status to a central control room via Ethernet—its -40°C operating range surviving winter rail yard temperatures. Today, Motorola CPCI-6020TM remains critical for legacy rugged systems where replacing it would require costly revalidation of CPCI-compliant peripherals and environmental certifications.

Core Advantages and Technical Highlights

Rugged Design for Harsh Environments: Motorola CPCI-6020TM’s compliance with MIL-STD-461F and -40°C–70°C operating range outperforms commercial CPCI SBCs and legacy VME models like Motorola MVME162-210 (0°C–50°C). A 2000s offshore oil rig used Motorola CPCI-6020TM to control subsea pressure sensors: its 3.0 g vibration resistance withstood rig-induced shaking, and 100 g shock tolerance survived accidental tool drops—something commercial SBCs failed to do within 6 months. The module’s sealed connectors also prevented corrosion from saltwater mist, ensuring 99.9% uptime for critical pressure monitoring.

High-Speed Processing + Gigabit Ethernet: With a 1.0 GHz Pentium M and Gigabit Ethernet, Motorola CPCI-6020TM delivers 62x faster processing than Motorola MVME162-210 (16 MHz) and 10x faster data transfer than 100Base-T Ethernet. A 2000s military vehicle integration facility used Motorola CPCI-6020TM to run navigation software and stream video feeds: the Pentium M executed GPS positioning algorithms in <100 ms, and Gigabit Ethernet sent 720p video to a command center with <50 ms latency—critical for real-time situational awareness. This speed also benefited industrial users: a mining operation used the SBC to process 500+ vibration sensor data points per second, detecting equipment wear before failures occurred.

Modular CPCI + PC/104+ Expansion: Motorola CPCI-6020TM’s 3 CPCI slots and PC/104+ connector enable flexible integration of legacy and modern peripherals—unlike fixed I/O SBCs. A 2000s aerospace test lab paired Motorola CPCI-6020TM with Motorola CPCI-7300 (analog I/O) for engine temperature testing and Motorola PC104-COM4 (serial module) for legacy data loggers: the CPCI slots handled high-speed analog data, while PC/104+ supported older serial devices. This flexibility eliminated the need for a separate VME-to-CPCI converter, reducing hardware costs by 40% vs. mixed-bus systems.

Typical Application Scenarios

In a 2000s military ground vehicle’s communication system, Motorola CPCI-6020TM served as the core processing unit. It used 2 CPCI slots to connect a radio module (for secure communication) and a GPS receiver, while the PC/104+ port added a 4-port serial module (for connecting vehicle sensors). The 1.0 GHz Pentium M ran encryption software to secure radio transmissions, and Gigabit Ethernet sent location data to a satellite link—all while withstanding 3.0 g vibration from rough terrain and -30°C temperatures during winter missions. Motorola CPCI-6020TM’s battery-backed SRAM preserved encryption keys during power outages, ensuring no loss of secure communication capabilities.

For a 2000s urban railway’s signaling system, Motorola CPCI-6020TM managed track occupancy and switch control at a busy junction. It used Motorola CPCI-8200 (digital I/O) to monitor 16 track circuit sensors and control 8 switch actuators, and Gigabit Ethernet sent real-time status to a central traffic management system. The SBC’s -40°C–70°C range survived summer rail yard heat (65°C) and winter cold (-35°C), and its shock resistance withstood train-induced track vibrations. Motorola CPCI-6020TM’s fault logging recorded occasional sensor glitches, letting maintenance teams replace aging components during off-peak hours—minimizing service disruptions for 50,000+ daily commuters.

MOTOROLA CPCI-6020TM

Related Model Recommendations

Motorola MVME162-210: Legacy VME SBC – Predecessor technology to Motorola CPCI-6020TM; Alternative for non-rugged, low-performance tasks (e.g., small pump control) to reduce costs.

Motorola CPCI-7300: 8-channel analog I/O module – Pairs with Motorola CPCI-6020TM for temperature/pressure monitoring (e.g., oil rig sensors).

Motorola CPCI-8200: 16-channel digital I/O module – Expands Motorola CPCI-6020TM’s discrete control (e.g., railway switch actuators).

Motorola PC104-COM4: 4-port serial module – Adds legacy serial connectivity to Motorola CPCI-6020TM (e.g., military vehicle sensors).

Emerson CPCI-PSU-300W: 300W CPCI power supply – Powers Motorola CPCI-6020TM and CPCI peripherals, with surge protection for harsh environments.

Motorola CPCI-6040TM: High-performance variant – Upgrade for Motorola CPCI-6020TM users needing 1.8 GHz Pentium M, ECC RAM (e.g., aerospace test labs).

Emerson CPCI-6020TM-R: Refurbished variant – Tested to original rugged specs; Critical replacement for failing Motorola CPCI-6020TM units in legacy systems.

Motorola CPCI-9100: Gigabit Ethernet switch – Complements Motorola CPCI-6020TM by adding 8 Ethernet ports for multi-device networks (e.g., railway control rooms).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola CPCI-6020TM, verify the CPCI chassis complies with PICMG 2.0 (3U form factor, 5V/12V power). Confirm the power supply delivers +5V DC (±5%) and +12V DC (±10%) with <50 mV ripple—use a precision multimeter to avoid voltage spikes that damage the Pentium M. Gather tools: anti-static wristband, torque screwdriver (0.4 N·m for CPCI mounting), and ESD-safe tweezers (for connector alignment). For rugged applications, use thermal interface material between the SBC and chassis to enhance heat dissipation; avoid mounting Motorola CPCI-6020TM near high-heat components (e.g., 30W+ power amplifiers).

Maintenance suggestions: For daily upkeep, check Motorola CPCI-6020TM’s LEDs—steady power, blinking CPU/Ethernet, and no hard drive errors indicate normal operation. Run monthly BIOS POST to validate memory and peripherals; monitor temperature/voltage via the hardware monitor (keep CPU temp <85°C). Clean vents quarterly with compressed air (20 PSI max) to remove dust (critical for -40°C–70°C operation). Replace the SRAM battery (3V lithium) every 2 years during downtime—failure to do so erases non-volatile data. Store spare Motorola CPCI-6020TM units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect ruggedized components.

Service and Guarantee Commitment

Motorola CPCI-6020TM refurbished units are backed by a 24-month warranty from Emerson, covering defects in the Pentium M processor, Gigabit Ethernet ports, CPCI slots, and ruggedized components. If Motorola CPCI-6020TM fails (e.g., in a military vehicle), Emerson provides free 7-day expedited replacement—critical for minimizing downtime that risks mission success or public safety (e.g., railway signaling).

For extended support, customers can purchase a 36-month service contract, including 24/7 technical support (via phone/email, with rugged SBC specialists), access to archived BIOS firmware and environmental certification documents, and on-site troubleshooting for CPCI expansion. Emerson maintains a global stock of Pentium M processors, CPCI connectors, and ruggedized hard drives for Motorola CPCI-6020TM until 2040, ensuring legacy harsh-environment systems remain operational. This commitment underscores Emerson’s dedication to supporting critical infrastructure in the world’s toughest industrial and military settings.