Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

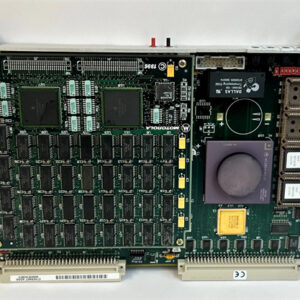

| Product Model | MOTOROLA FLN3524A |

| Manufacturer | Motorola |

| Product Category | Remote data acquisition and connectivity module for industrial PLC systems |

| Model Type | ACE3600 |

| Dimensions | 2.3″ x 9.0″ x 7.0″ (5.7 cm x 22.9 cm x 17.8 cm) |

| Weight | 1 lbs 0.0 oz (0.5 kg) |

| Tariff Code | 8537109060 |

| Communication Interfaces | – Three serial interfaces: One dedicated to MPI communication, one for Profibus – DP slave interface (both support transfer rates up to 12 Mbit/s), and a standard serial interface for point – to – point (PTP) communication – One Ethernet (RJ – 45) network interface |

| Function | Remote program download and remote data collection for PLC products with RJ – 45 network interface |

| Compatibility | PLC products with RJ – 45 network interface |

| Installation | Plug – and – play, easy integration with PLC supporting software using Yitang “Yiyun” service platform and netcom software |

| Product Status | May be available new or used/refurbished in the market; stock availability varies |

| Warranty | Varies by supplier; some offer a 3 – month warranty for used units, and up to one – year for new units |

MOTOROLA FLN3524A

Product Introduction

The MOTOROLA FLN3524A is an industrial – grade module designed to meet the demands of modern industrial control and monitoring systems. Specifically engineered for PLC (Programmable Logic Controller) products, it offers a seamless solution for remote operations. Its compact dimensions of 2.3″ x 9.0″ x 7.0″ (5.7 cm x 22.9 cm x 17.8 cm) and lightweight design of 1 lbs 0.0 oz (0.5 kg) make it suitable for installation in various industrial setups where space is a constraint.

The FLN3524A serves as a crucial link between PLC systems and remote monitoring or control stations. By leveraging its advanced communication interfaces, it enables efficient data transfer and remote access to PLC programs, enhancing the overall functionality and flexibility of industrial control systems.

Core Advantages and Technical Highlights

Robust Remote Data Acquisition and Program Download

One of the key features of the FLN3524A is its ability to provide remote program download and data collection for PLC products equipped with an RJ – 45 network interface. For example, when integrated with a PLC – 509 (which has an RJ – 45 interface), it can network through the carrier’s 3G network. This allows industrial operators to remotely update PLC programs without the need for on – site physical access. In a large – scale manufacturing plant spread across different locations, engineers can easily upload new control algorithms or software patches to the PLCs, ensuring smooth and optimized operations.

The remote data collection aspect is equally important. It can gather real – time data from the PLC, such as sensor readings, machine status, and production metrics. This data can then be transmitted to a central control room or a cloud – based platform for further analysis. For instance, in a food processing factory, the FLN3524A can collect data on temperature, pressure, and conveyor belt speeds from PLC – controlled equipment, enabling managers to monitor and adjust production processes in real – time.

Multiple Communication Interfaces for Versatility

The FLN3524A comes with three serial interfaces and one Ethernet port, each serving a specific purpose. The serial interfaces are highly versatile. The MPI (Multi – Point Interface) communication interface is useful for communicating with other Siemens – compatible devices in a multi – node network. The Profibus – DP slave interface, with its high transfer rate of up to 12 Mbit/s, is ideal for connecting to Profibus – DP master devices in industrial automation networks. This allows for fast and reliable data exchange between the FLN3524A – equipped PLC and other components in the network, such as sensors, actuators, and other control modules.

The standard serial interface can be used to establish point – to – point (PTP) communication, which is beneficial for connecting to devices that require a direct, dedicated connection. The Ethernet (RJ – 45) port, on the other hand, provides high – speed network connectivity, enabling seamless integration with modern industrial Ethernet networks. This combination of interfaces makes the FLN3524A adaptable to a wide range of industrial communication protocols and network topologies.

Easy Integration and Plug – and – Play Functionality

Installation and integration of the FLN3524A are designed to be hassle – free. It follows a plug – and – play principle, meaning that once physically connected, it can start functioning without extensive configuration. By leveraging the Yitang “Yiyun” service platform and netcom software, it can be easily integrated with PLC supporting software. This eliminates the need for additional integration development work, saving both time and resources for industrial system integrators and end – users. In a retrofit project where an existing PLC system needs to be upgraded to support remote operations, the FLN3524A can be quickly installed and integrated, minimizing downtime and disruption to production.

Typical Application Scenarios

Industrial Automation in Manufacturing Plants

In manufacturing plants, the FLN3524A plays a vital role in industrial automation. It can be integrated with PLCs that control various manufacturing processes, such as robotic arms, conveyor systems, and packaging machines. For example, in an automotive assembly line, PLCs control the movement of robotic arms that perform tasks like welding, painting, and part installation. The FLN3524A can be used to remotely monitor the performance of these PLC – controlled robotic arms, collect data on cycle times, error rates, and component usage. This data can then be used to optimize the production process, improve efficiency, and reduce maintenance costs.

Moreover, if there is a need to update the control programs of the robotic arms to accommodate a new product design or production requirement, the FLN3524A enables engineers to remotely download the new programs to the PLCs, eliminating the need for technicians to physically access each robot on the factory floor.

Remote Monitoring and Maintenance of Industrial Equipment

For industrial equipment located in remote areas or harsh environments, the FLN3524A is an invaluable tool. Consider a wind farm spread across a large geographical area. PLCs are used to control the operation of wind turbines, including blade pitch adjustment, generator speed control, and power conversion. The FLN3524A can be installed in each turbine’s control system to provide remote monitoring and maintenance capabilities. Technicians can remotely access the PLCs to check the status of the turbines, collect data on power generation, wind speed, and turbine health.

In case of a fault or maintenance requirement, they can use the FLN3524A to remotely download software updates or diagnostic tools to the PLCs. This significantly reduces the need for on – site visits, which can be costly and time – consuming, especially in remote or difficult – to – access locations. It also improves the overall service efficiency, as issues can be detected and resolved more quickly, minimizing downtime and maximizing the energy production of the wind farm.

Related Product Recommendations

PLC – Compatible Accessories: To fully utilize the capabilities of the FLN3524A, consider pairing it with PLC – compatible accessories such as additional communication cables (both serial and Ethernet), terminal blocks for secure wiring connections, and power adapters if the module requires a specific power source. These accessories ensure a stable and reliable connection between the FLN3524A and the PLC system.

Industrial – Grade Routers and Switches: Since the FLN3524A relies on network connectivity for remote operations, high – quality industrial – grade routers and switches are recommended. These devices are designed to withstand harsh industrial environments, provide stable network connections, and support the necessary network protocols for seamless communication between the FLN3524A – equipped PLCs and remote monitoring stations. For example, some industrial routers offer features like VPN (Virtual Private Network) support, which is crucial for secure remote access to the PLC systems.

PLC Supporting Software and Configuration Tools: To effectively configure and manage the FLN3524A and the associated PLCs, use reliable PLC supporting software and configuration tools. These software solutions provide an intuitive user interface for programming the PLCs, setting up communication parameters for the FLN3524A, and monitoring the overall system performance. Some software also offers advanced features like data visualization, historical data logging, and alarm management, enhancing the overall functionality of the industrial control system.

MOTOROLA FLN3524A

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installation, ensure that the target PLC system has an available RJ – 45 network interface. Verify that the physical installation location has sufficient space to accommodate the FLN3524A’s dimensions. Gather the necessary cables, such as Ethernet cables for network connectivity and appropriate serial cables if using the serial interfaces. Use anti – static equipment, such as an anti – static wristband, to protect the module from electrostatic discharge during handling.

Commissioning

Physically connect the FLN3524A to the PLC’s RJ – 45 network interface using a suitable Ethernet cable. If using the serial interfaces, connect the relevant serial cables to the appropriate devices. Power on the PLC system and the FLN3524A (if it has its own power source). The module should automatically detect the network and start functioning in a plug – and – play manner. Use the PLC supporting software to verify the connection and check the status of the FLN3524A. Ensure that the communication parameters, such as IP address (for Ethernet) and serial baud rate, are correctly configured.

Maintenance

Regularly check the network connectivity of the FLN3524A. Monitor for any dropped connections or slow data transfer rates, which could indicate a network issue. Inspect the physical connections of all cables to ensure they are secure. Periodically update the firmware of the FLN3524A if new versions are available from Motorola. This can improve performance, fix bugs, and add new features. In case of any hardware failures, such as a malfunctioning Ethernet port or serial interface, contact the manufacturer or an authorized service provider for replacement or repair.

Service and Guarantee Commitment

The service and guarantee for the MOTOROLA FLN3524A vary depending on the supplier. Some suppliers offer a 3 – month warranty for used units, while new units may come with a one – year warranty. The warranty typically covers defects in materials and workmanship. Technical support may be available from the manufacturer or authorized resellers. They can provide assistance with installation, configuration, and troubleshooting. In case of any issues, customers can contact the support team for guidance on resolving problems or initiating the warranty claim process if the module fails under normal use conditions.