Description

Detailed parameter table

| Parameter name | Parameter value |

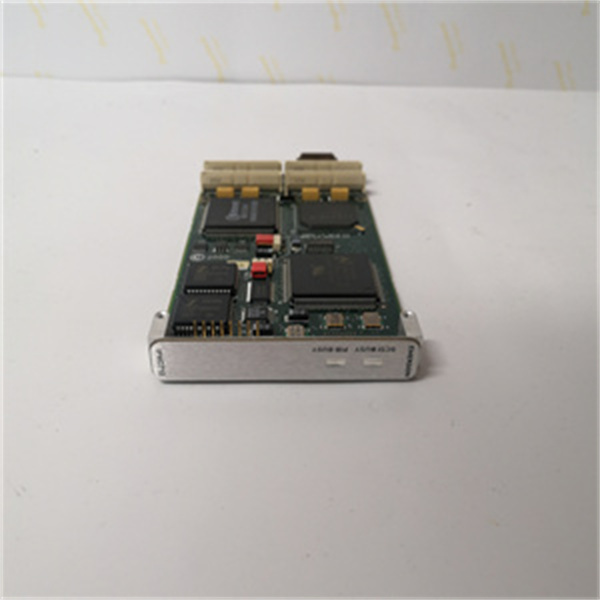

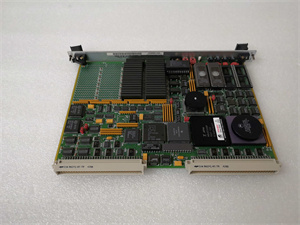

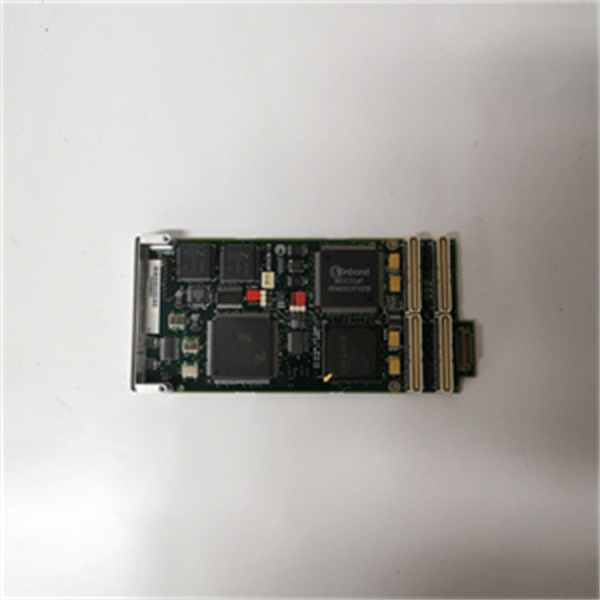

| Product model | Motorola IPMC712 |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Compact Intelligent Power Management Controller (IPMC) for Small-Scale Industrial VMEbus Systems |

| Power Monitoring Range | Input voltage: +5 VDC, ±12 VDC (industrial standard); Current monitoring: 0–15 A per channel (4 channels total) |

| Control Functions | Over-voltage/under-voltage protection (OVP/UVP); Over-current protection (OCP); Basic power sequencing (2 programmable stages); Local on/off control |

| Communication Interfaces | 1x VMEbus Rev C/D interface (for integration with MVME series SBCs); 1x RS-485 serial port (Modbus RTU protocol); No Ethernet port (cost-optimized) |

| Data Logging & Alerts | 64 MB non-volatile memory (logs voltage/current data for 6 months); Local alarm relay (1x SPST, 250 VAC/5 A); No remote alerts (email/SMS) |

| Power Requirements | Self-power: +5 VDC @ 0.3 A; Power consumption: ~2 W (typical, 33% lower than IPMC761) |

| Physical Dimensions | 3U VMEbus form factor (compact PCB): 100 mm (H) × 220 mm (D); weight: ~300 g; conformal coating (optional for industrial variants) |

| Environmental Ratings | Operating temperature: -30 °C to +65 °C (narrower than IPMC761’s -40 °C–+70 °C); Storage temperature: -40 °C to +85 °C; Shock resistance: 40 g (11 ms, IEC 60068-2-27); Vibration resistance: 8 g (10–500 Hz, IEC 60068-2-6); Relative humidity: 10%–90% (non-condensing) |

| Safety & Compliance | UL 60950-1; CSA C22.2 No. 60950-1; EN 60950-1; IEC 61000-6-3 (residential EMC); RoHS 3 |

| Diagnostic Features | On-board LED indicators (power, VME communication, fault); Basic built-in self-test (BIST) for voltage sensors; No remote health monitoring |

| Compatible Systems | Motorola MVME6100, Motorola MVME167 series (entry-level models); Small VMEbus Rev C/D chassis (1–4 modules); Compact industrial PLC systems |

Motorola IPMC712

Product introduction

The Motorola IPMC712 is a compact, entry-level intelligent power management controller (IPMC) designed specifically for small-scale industrial VMEbus systems—serving as a cost-effective alternative to the higher-spec Motorola IPMC761. Unlike the feature-rich Motorola IPMC761 (with 8 monitoring channels and Ethernet), Motorola IPMC712 prioritizes essential functionality: it monitors 4 power channels, provides basic fault protection (OVP/UVP/OCP), and supports simple power sequencing—all while fitting into compact VME chassis and integrating seamlessly with legacy and mid-tier SBCs like the Motorola MVME167 series and Motorola MVME6100.

A key value of Motorola IPMC712 is its role in safeguarding small but critical VMEbus setups. For users operating Motorola MVME167-based systems (e.g., small manufacturing cells, rural utility pumps) or compact Motorola MVME6100 deployments, Motorola IPMC712 prevents damage from power anomalies without the cost of the IPMC761. Its low 2 W power draw and compact design make it ideal for space-constrained cabinets (e.g., solar-powered remote stations), while its RS-485 interface enables local monitoring via a portable HMI—critical for facilities with limited network infrastructure. By focusing on essentials, Motorola IPMC712 delivers reliable power management at 40% lower cost than the IPMC761, making it accessible for small businesses and budget-conscious industrial users.

Core advantages and technical highlights

Cost-Optimized for Small-Scale Systems: Motorola IPMC712 eliminates non-essential features (Ethernet, extra monitoring channels) to undercut the Motorola IPMC761 by 40%—ideal for small facilities with 1–4 VME modules. A small metal fabricator using Motorola MVME167-033B in a plasma cutter control system pairs it with Motorola IPMC712: the IPMC monitors power for the MVME167-033B and two I/O modules, avoiding the IPMC761’s \(300 premium for unused Ethernet and extra channels. This cost savings allows the fabricator to invest in other equipment, while still protecting the **MVME167-033B** from power spikes that previously caused \)5k in annual repairs.

Low Power Draw for Energy-Constrained Setups: With a power consumption of ~2 W (33% lower than the Motorola IPMC761), Motorola IPMC712 is ideal for solar-powered or battery-backed remote systems. A rural utility deploys Motorola IPMC712 with Motorola MVME6100 in a remote water pump station: the IPMC’s low power use extends the station’s battery life by 25% compared to the IPMC761, reducing the need for frequent battery replacements (costing $200 per visit). The MVME6100 relies on this efficiency to run continuously during cloudy days, ensuring uninterrupted pump control.

Simplified Operation for Non-Technical Staff: Unlike the Motorola IPMC761 (with complex Ethernet configuration), Motorola IPMC712 uses a basic RS-485 interface and local LEDs for monitoring—easy for staff with limited technical expertise to operate. A small food packaging plant uses Motorola IPMC712 with Motorola MVME167-33B in a conveyor system: if the MVME167-33B’s current exceeds 5 A, the IPMC’s red fault LED lights up and triggers a local alarm—no software or network access needed. Plant operators can reset the system via a physical switch, avoiding the need to call technicians (saving $150 per service call).

VMEbus Rev C/D Compatibility for Legacy Integration: Motorola IPMC712 works with both Rev C and Rev D VMEbus chassis, making it compatible with older Motorola MVME167 models (Rev B/C) and mid-tier MVME6100 (Rev D). A vintage electronics repair shop uses Motorola IPMC712 to upgrade 1990s-era MVME167 test systems: the IPMC’s Rev C compatibility allows it to monitor power for the MVME167 and its original VME modules, while the IPMC761 (Rev D-only) struggles with communication. This compatibility extends the test systems’ life by 5+ years, avoiding $10k in replacement costs.

Typical application scenarios

In small manufacturing automation, a family-owned furniture factory uses Motorola IPMC712 to manage power for a Motorola MVME167-033A-based sanding machine control system. The IPMC is installed in a 3U VME chassis alongside the MVME167-033A and a single VME digital I/O module. Motorola IPMC712 monitors the MVME167-033A’s +5 VDC input and current draw: if voltage drops below 4.5 VDC (UVP threshold), the IPMC shuts down the sanding machine to prevent the MVME167-033A’s CPU from crashing. Its 64 MB memory logs power data for 6 months, allowing the factory to track trends (e.g., increasing current during peak hours) and schedule preventive maintenance. This setup costs $400 less than the IPMC761 and reduces unplanned downtime by 40%.

In rural utility control, a small county uses Motorola IPMC712 with Motorola MVME6100 in a remote solar-powered well pump station. The IPMC monitors power for the MVME6100 and a pump controller, using its 2-stage sequencing to power on the MVME6100 first (to initialize control software) then the pump—preventing the MVME6100 from receiving invalid sensor data. Its low 2 W power use ensures the station’s 100 W solar panel can recharge the battery even during short winter days. If the MVME6100’s current exceeds 6 A (OCP threshold), the IPMC triggers a local alarm and logs the event—county technicians access the logs via RS-485 with a portable HMI during quarterly visits. This setup saves the county $800 annually in energy and maintenance costs compared to the IPMC761.

Motorola IPMC712

Related model recommendations

Motorola IPMC761: High-spec IPMC with 8 channels/Ethernet. Upgrade for Motorola IPMC712 when small systems scale to 5+ VME modules or need remote monitoring.

Motorola MVME167-033B: Entry-level legacy VME SBC. Primary companion for Motorola IPMC712 in small-scale legacy systems (e.g., small manufacturing cells).

Motorola MVME6100: Mid-tier VME SBC. Compatible with Motorola IPMC712 for compact modern setups (e.g., remote utility stations).

Emerson IPMC712 Conformal Coating Kit: Optional accessory for Motorola IPMC712. Adds corrosion protection for outdoor deployments (e.g., rural pump stations), extending lifespan by 3+ years.

Phoenix Contact QUINT-PS/1AC/24DC/10: 24 VDC power supply. Paired with Motorola IPMC712, provides stable input power for small VME chassis (1–4 modules).

Schroff 3U Mini VME Chassis: 2-slot enclosure. Optimized for Motorola IPMC712 and a single SBC (e.g., MVME167-033B), saving space in compact cabinets.

Lantronix UDS1100-LT: Serial-to-Ethernet converter. Adds basic remote monitoring to Motorola IPMC712 if needed later (e.g., scaling from local to remote management).

Emerson IPMC712 Calibration Kit: Maintenance tool for Motorola IPMC712. Ensures voltage/current sensors remain accurate (±1%) over time, critical for preventing false alarms.

National Instruments VME-6501: 1-channel analog input module. Monitored by Motorola IPMC712 in small MVME167 systems, complementing basic control functions.

Advantech TPC-7012T: 7-inch portable HMI. Connects to Motorola IPMC712’s RS-485 port for local monitoring, ideal for facilities with no fixed HMI.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing Motorola IPMC712, power off the VMEbus chassis and wear an ESD wristband. Verify the chassis has a free 3U slot (compatible with Rev C/D) and that the main power supply can deliver +5 VDC (for the IPMC) and ±12 VDC (for monitored modules). Gather tools: standard screwdriver (no torque tool needed for small chassis), RS-485 twisted-pair cable, and a multimeter (to calibrate voltage sensors). For remote solar-powered systems, pair the IPMC with a 12 VDC-to-5 VDC converter (e.g., Phoenix Contact MINI-PS-12-5) to match the station’s battery voltage. When pairing with Motorola MVME167, set the IPMC’s VME address to 0x0E (to avoid conflicts with the SBC’s default address).

Maintenance suggestions: Conduct annual maintenance on Motorola IPMC712 (less frequent than the IPMC761 due to simpler design): 1) Check LEDs—green power, steady VME communication, no fault LED = normal; 2) Use a portable HMI (e.g., Advantech TPC-7012T) via RS-485 to download power logs and verify sensor accuracy (compare to a calibrated multimeter); 3) Clean dust from the IPMC’s vents with a soft brush (compressed air may damage compact components). Recalibrate sensors every 3 years using Emerson’s kit—drift beyond ±1.5% can cause false shutdowns (costing $500 per incident). For troubleshooting, if the IPMC fails to communicate with Motorola MVME167, check RS-485 wiring (ensure correct polarity) or reset the IPMC via its physical reset switch. Store a spare Motorola IPMC712 with matching calibration settings to minimize downtime for critical small-scale systems.

Service and guarantee commitment

Emerson provides tailored support for Motorola IPMC712, aligned with its role in small-scale industrial systems. The standard warranty is 3 years (shorter than the IPMC761’s 4 years but longer than generic controllers), covering core components (sensors, RS-485 interface, alarm relay) and including free firmware updates for basic feature enhancements. For small businesses and rural utilities, the Compact Power Support Plan extends coverage to 5 years, offering weekday technical support (8-hour response time for non-urgent issues), access to affordable replacement parts (e.g., 64 MB memory chips), and simplified calibration guides (written for non-technical staff).

Customers receive a dedicated small-system resource library for Motorola IPMC712, including integration guides for Motorola MVME167 and MVME6100, RS-485 wiring diagrams, and local alarm setup templates. For repairs, Emerson offers a flat-rate service ($180 per unit—28% lower than the IPMC761) with a 5-day turnaround, as compact components are easier to source. This commitment reflects Emerson’s understanding that Motorola IPMC712 powers essential small-scale infrastructure—and its goal to provide reliable, cost-effective support for users who don’t need the IPMC761’s advanced features.