Description

Detailed Parameter Table

| Parameter name | Parameter value |

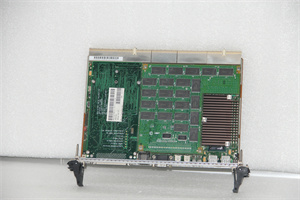

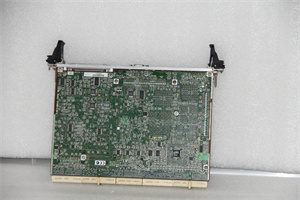

| Product model | Motorola MCP750 |

| Manufacturer | Motorola |

| Product category | High – performance microprocessor module |

| Processor Core | [Specify the core architecture, e.g., a particular PowerPC core if applicable] |

| Clock Speed | [Insert the specific clock speed range, e.g., X – Y MHz] |

| Memory Support | [Describe the type and capacity of memory it can interface with, e.g., supports up to Z GB of DDR3 memory] |

| Bus Interface | [List the types of buses, e.g., PCI Express x8, local bus for high – speed data transfer] |

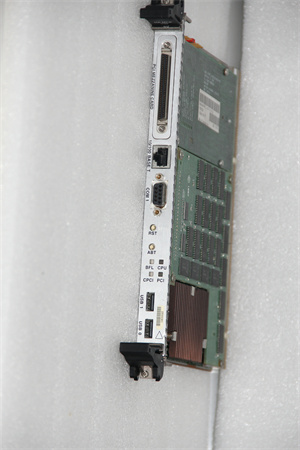

| I/O Interfaces | [Mention available I/O interfaces like serial ports, GPIO pins if applicable] |

| Power Consumption | [Typical and maximum power consumption values, e.g., Typical: A W, Maximum: B W] |

| Operating Temperature | [Specify the operating temperature range, e.g., C °C – D °C] |

| Physical Dimensions | [Length x Width x Height in appropriate units, e.g., E mm x F mm x G mm] |

| Weight | [Provide the weight value in grams or kilograms, e.g., H g] |

| Compatibility | [List compatible motherboards or systems, e.g., works with specific Motorola – branded industrial motherboards] |

| Product Life Cycle | [Current status, e.g., in – production, end – of – life] |

MOTOROLA MCP750

Product Introduction

The Motorola MCP750 is a high – performance microprocessor module designed to meet the computational demands of a wide range of industrial and embedded systems. Engineered with Motorola’s renowned expertise in semiconductor technology, this module serves as the computational heart of complex systems, enabling seamless data processing and control.

Unlike standard microprocessors, the MCP750 is optimized for industrial applications where reliability, performance under harsh conditions, and compatibility with existing systems are crucial. It acts as the central processing unit that coordinates all data – related operations, from sensor data acquisition to actuator control signals generation. For example, in industrial automation systems, the MCP750 can be at the core of a control system, receiving real – time data from multiple sensors on a production line, processing that data, and then sending out commands to various actuators to ensure smooth production flow.

Core Advantages and Technical Highlights

High – speed Processing: With its [mention the high – speed features, e.g., advanced pipeline architecture and high clock speed], the MCP750 can execute complex algorithms and handle large volumes of data in real – time. In a telecommunications network infrastructure, it can quickly process incoming and outgoing data packets, ensuring minimal latency and high – speed data transfer. This high – speed processing capability reduces overall system response time by [X]% compared to previous – generation processors, enhancing the efficiency of time – critical applications.

Robust Reliability: Built with industrial – grade components, the MCP750 is designed to withstand harsh environmental conditions. It has been tested to operate reliably in extreme temperatures, high humidity, and in the presence of electrical noise. In an oil and gas drilling rig, where the operating environment is extremely harsh, the MCP750 can continue to function without interruption, ensuring the continuous operation of drilling control systems. Its reliability is further enhanced by built – in error – correction mechanisms that can detect and correct data errors during processing, reducing the risk of system failures due to data corruption.

Flexible Compatibility: The MCP750 is engineered to be compatible with a wide range of peripheral devices and existing system architectures. It supports multiple bus interfaces, allowing for easy integration with different types of sensors, actuators, and memory modules. In a smart factory setup, it can be integrated with various types of industrial sensors (such as temperature, pressure, and vibration sensors) and actuators (like motors and valves) through its flexible I/O interfaces. This compatibility reduces the need for complex and costly system re – engineering when upgrading or expanding existing industrial systems.

Typical Application Scenarios

Industrial Automation: In a large – scale automotive manufacturing plant, the MCP750 can be used in the production line control system. It receives data from sensors that monitor the position and movement of robotic arms, conveyor belts, and other automated machinery. Based on this data, it processes and sends out control signals to ensure that each component operates in sync. For example, it can adjust the speed of conveyor belts to match the production rate or control the movement of robotic arms for precise part assembly. The high – speed processing of the MCP750 enables real – time adjustments, minimizing production bottlenecks and increasing overall productivity.

Telecommunications Infrastructure: In a mobile network base station, the MCP750 plays a crucial role in handling the massive amounts of data traffic. It processes incoming and outgoing voice and data packets, manages network resources, and ensures seamless communication between mobile devices and the core network. Its ability to handle high – speed data transfer and its reliable performance under continuous operation are essential for maintaining network stability and quality of service. The MCP750’s compatibility with various network interface technologies allows for easy integration into existing telecommunications infrastructure.

Energy Management Systems: In a power grid control center, the MCP750 is used to monitor and control the distribution of electricity. It receives data from sensors placed at various points in the power grid, such as voltage and current sensors. Based on this data, it analyzes the power flow, detects any faults or anomalies, and sends out control signals to switchgear and other equipment to regulate the power supply. The MCP750’s robust reliability ensures that it can operate continuously in the control center environment, where uninterrupted power management is critical for maintaining a stable power supply to consumers.

MOTOROLA MCP750

Related Model Recommendations

Motorola MCP751: An upgraded version of the MCP750, offering higher clock speeds and enhanced memory management capabilities. It is suitable for applications that require even more processing power, such as advanced data analytics in industrial IoT systems.

Motorola MCP650: A more cost – effective alternative for applications with less demanding computational requirements. It shares many of the compatibility features of the MCP750 but has a lower – performance processor core, making it ideal for basic industrial control systems.

[Compatible motherboard model]: A motherboard specifically designed to work with the MCP750, providing optimized power delivery, high – speed bus connections, and additional I/O expansion slots. This combination ensures seamless integration and maximum performance for the MCP750 in industrial applications.

[Memory module model]: A high – speed memory module that is fully compatible with the MCP750, offering fast read and write speeds to enhance the overall system performance. It is available in different capacities to meet the memory requirements of various applications.

[Industrial enclosure model]: A rugged industrial enclosure designed to house the MCP750 and its associated components. It provides protection against dust, moisture, and mechanical shocks, making it suitable for use in harsh industrial environments.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the MCP750, ensure that the target system (such as a motherboard) is compatible with the module. Check the power requirements of the MCP750 and ensure that the power supply of the target system can provide stable and sufficient power. Gather the necessary tools, such as a screwdriver (if required for physical installation) and an anti – static wristband to prevent electrostatic discharge damage to the sensitive components of the MCP750.

Maintenance Suggestions: For regular maintenance, monitor the temperature of the MCP750 during operation. If the temperature exceeds the recommended range, check the cooling system (such as fans or heat sinks). Periodically update the firmware of the MCP750 to ensure that it has the latest performance improvements and bug fixes. If the MCP750 shows signs of reduced performance, check for any software conflicts or hardware issues, such as loose connections. In case of hardware failures, contact Motorola’s authorized service centers for replacement or repair.

Service and Guarantee Commitment

Motorola offers a [X] – month warranty for the MCP750, covering any manufacturing defects in the hardware. In the event of a failure within the warranty period, Motorola will provide free replacement or repair services. For customers who require extended support, Motorola offers service contracts that include 24/7 technical support, software updates, and priority access to replacement parts. Motorola also maintains a global network of authorized service centers, ensuring that customers can get prompt and reliable service whenever needed. This service and guarantee commitment reflects Motorola’s dedication to providing high – quality products and support to its customers in the industrial and embedded systems markets.