Description

Detailed Parameter Table

**

| Parameter Name | Parameter Value |

| Product Model | MOTOROLA MPC2004 |

| Manufacturer | Motorola |

| Product Category | Industrial – grade controller, suitable for simplex, dual redundant, and triple redundant systems |

| Dimensions | N/A (not specified in common sources, but designed for industrial installation) |

| Weight | N/A (not specified in common sources) |

| Communication Interfaces | – Industrial standard Ethernet for monitoring interfaces of I/O, controllers, operators, and maintenance stations, as well as third – party systems – Four RJ – 45 connectors for serial ports on the front panel of the board – An AUI connector for Ethernet – A 68 – pin SCSI interface connector |

| Processor | Superscalar MC 68060 microprocessor (risc hybrid architecture); optional MC 68LC060 for cost – sensitive applications without high floating – point performance needs |

| Memory Options | SDRAM with ECC option, EPROM/ROM, flash, and battery – backed SRAM |

| Industry Pack Interface | 32 – bit data path for industry pack modules to the local MC 68060 bus; supports up to two single – wide industry pack modules while occupying only one VME slot |

| Power Requirements | N/A (designed to operate with standard industrial power sources, but specific values not provided) |

| Operating Temperature Range | N/A (designed for industrial environments, but exact range not specified) |

| Product Status | May be available new or used/refurbished in the market; stock availability varies |

| Warranty | Some sources offer a one – year warranty, but it may vary by supplier |

| Compatibility | Compatible with industrial systems that require high – speed network I/O; works well in VMEbus – based systems |

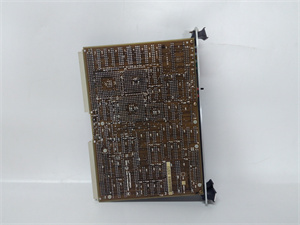

MOTOROLA MPC2004

Product Introduction

The MOTOROLA MPC2004 is an industrial – grade controller that stands out for its versatility and high – performance capabilities. Engineered to meet the demands of complex industrial setups, it is well – suited for simplex, dual redundant, and triple redundant systems. The use of industrial standard Ethernet communication in the MPC2004 enables seamless connectivity between various components such as I/O devices, controllers, operator stations, maintenance stations, and third – party systems. This makes it an ideal choice for industries where reliable and high – speed data transfer is crucial.

The MPC2004’s design allows for easy integration into existing industrial infrastructure. With its well – defined interface options, including multiple serial ports, Ethernet connectors, and an SCSI interface, it can be connected to a wide range of peripheral devices. This flexibility in connectivity makes it adaptable to different industrial applications, whether it’s in manufacturing plants, aerospace facilities, or military equipment.

Core Advantages and Technical Highlights

High – Performance Processor for Intensive Computing

The MPC2004 features the superscalar MC 68060 microprocessor, which is based on a RISC hybrid architecture. This processor is a powerhouse when it comes to integer and floating – point performance. Its object – code compatibility with earlier generations of processors is a significant advantage. It allows for a substantial performance increase in new applications while still preserving the software investment made in older systems. For example, in industrial control applications where complex algorithms need to be executed in real – time, the MC 68060 can handle the computational load efficiently.

In cost – sensitive applications where floating – point performance is not a primary requirement, the optional MC 68LC060 can be selected. This provides users with the flexibility to choose a processor configuration that best suits their budget and application needs without sacrificing essential functionality.

Robust Memory Options for Data Storage

The MPC2004 offers a diverse set of memory options, including SDRAM with an ECC (Error – Correcting Code) option, EPROM/ROM, flash memory, and battery – backed SRAM. The SDRAM with ECC option ensures data integrity, especially in environments where data corruption due to electrical noise or other factors is a concern. The battery – backed SRAM is useful for storing critical data that needs to be retained even during power outages. For instance, in a manufacturing process control system, the battery – backed SRAM can store the current state of the production line, allowing for a seamless restart when power is restored.

The availability of different memory types caters to various data storage and retrieval requirements. Flash memory can be used for storing firmware and other non – volatile data, while EPROM/ROM can hold permanent program code. This combination of memory options provides the MPC2004 with the ability to handle different types of data in an industrial setting.

Versatile Industry Pack Interface

The industry pack logic interface in the MPC2004 is a key feature. It provides a 32 – bit data path for industry pack modules to the local MC 68060 bus. Industry pack modules are highly versatile and can offer a wide range of connections to “real – world” applications. These include I/O, control, interface, analog, and digital functions. The ability to support up to two single – wide industry pack modules while occupying only one VME slot is a space – saving and cost – effective advantage.

As industrial processes evolve and I/O needs change, new industry pack modules can be easily installed in the MPC2004. This preserves the overall investment made in the system, as users don’t need to replace the entire controller but can simply upgrade the relevant modules. For example, if a manufacturing plant decides to add new sensors or actuators to its production line, new industry pack modules can be added to the MPC2004 to interface with these devices.

Typical Application Scenarios

Industrial Control in Manufacturing Plants

In manufacturing plants, the MPC2004 can be at the heart of the industrial control system. It can be used to control and monitor various manufacturing processes, such as the operation of robotic arms, conveyor systems, and automated assembly lines. For example, in an automotive manufacturing plant, the MPC2004 can control the movement of robotic arms that perform tasks like welding, painting, and part installation. The high – speed network I/O capabilities of the MPC2004 enable it to receive real – time data from sensors on the production line, such as position sensors on robotic arms and proximity sensors on conveyor belts.

Based on this data, the MPC2004 can make quick decisions to adjust the manufacturing process. It can also communicate with other controllers and operator stations in the plant, ensuring that the entire production process runs smoothly and efficiently. In case of any issues or malfunctions, the MPC2004 can send alerts to maintenance stations, allowing for timely repairs and minimizing downtime.

Aerospace and Military Applications

In aerospace and military applications, reliability and high – performance computing are of utmost importance. The MPC2004 meets these requirements with its robust design and powerful processor. In aerospace, it can be used in aircraft avionics systems to control and monitor various functions, such as flight control systems, navigation systems, and communication systems. The ability to operate in simplex, dual redundant, or triple redundant configurations ensures that the avionics system remains operational even in the event of component failures.

In military applications, the MPC2004 can be used in military vehicles, weapons systems, and communication networks. Its industrial – grade construction makes it suitable for harsh environments, and its high – speed data transfer capabilities are essential for real – time communication and control in military operations. For example, in a military command and control center, the MPC2004 can be used to manage and analyze data from multiple sources, including surveillance drones, ground – based sensors, and communication networks.

MOTOROLA MPC2004

Related Product Recommendations

Industry Pack Modules: To fully utilize the capabilities of the MPC2004’s industry pack interface, a variety of industry pack modules are recommended. These can include I/O modules for expanding digital and analog input/output capabilities, communication modules for adding additional network interfaces (such as CAN bus or wireless communication), and control modules for specific industrial control functions.

Ethernet Switches and Routers: Since the MPC2004 relies on Ethernet communication, high – quality industrial – grade Ethernet switches and routers are essential. These devices can provide reliable network connectivity, manage network traffic, and ensure seamless communication between the MPC2004 and other components in the industrial network. Some industrial Ethernet switches offer features like redundant power supplies and advanced network management capabilities, which are beneficial in industrial environments.

Power Supplies: A suitable industrial – grade power supply should be selected to power the MPC2004. The power supply should be able to provide stable power in industrial environments, with features like over – voltage protection, under – voltage protection, and noise filtering. Some power supplies are designed to work with a wide range of input voltages, which is useful in different geographical locations or industrial setups.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installation, ensure that the target industrial system has a suitable location for the MPC2004. Verify that the power source is compatible with the controller’s requirements (although specific power requirements are not widely documented, it is designed for standard industrial power sources). Gather the necessary cables, such as Ethernet cables for network connectivity, serial cables for the serial ports, and any cables required for connecting to SCSI devices. Use anti – static equipment, such as an anti – static wristband, to protect the MPC2004 from electrostatic discharge during handling.

Commissioning

Physically install the MPC2004 in the appropriate location, such as a VMEbus slot if applicable. Connect all the necessary cables, including the Ethernet cables to the network, serial cables to relevant devices, and SCSI cables if using SCSI – connected peripherals. Power on the system. The MPC2004 should start initializing. Use appropriate software tools (such as those provided by Motorola or third – party industrial control software) to configure the communication parameters, such as IP addresses for Ethernet, serial baud rates, and SCSI settings. Verify the connectivity with other devices in the network and test the functionality of the MPC2004 by running basic diagnostic tests.

Maintenance

Regularly check the network connectivity of the MPC2004. Monitor for any dropped connections or slow data transfer rates, which could indicate network issues. Inspect the physical connections of all cables to ensure they are secure. Periodically update the firmware of the MPC2004 if new versions are available from Motorola. This can improve performance, fix bugs, and add new features. In case of any hardware failures, such as a malfunctioning Ethernet port or serial interface, contact the manufacturer or an authorized service provider for replacement or repair. If using industry pack modules, also check the functionality of these modules regularly and replace them if they show signs of failure.

Service and Guarantee Commitment

The service and guarantee for the MOTOROLA MPC2004 vary depending on the supplier. Some sources offer a one – year warranty, which typically covers defects in materials and workmanship. Technical support may be available from the manufacturer or authorized resellers. They can provide assistance with installation, configuration, and troubleshooting. In case of any issues, customers can contact the support team for guidance on resolving problems or initiating the warranty claim process if the MPC2004 fails under normal use conditions. However, it’s important to note that as the product may be available in new or used/refurbished states, the warranty terms and availability of support may differ based on the product’s condition and the source of purchase.